Muitlaxial tension test machine

A technology of tensile testing machine and extensometer, which is applied in the direction of applying stable tension/compression to test the strength of materials, and can solve problems such as unevenness and inability to stably stretch and stress thin materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

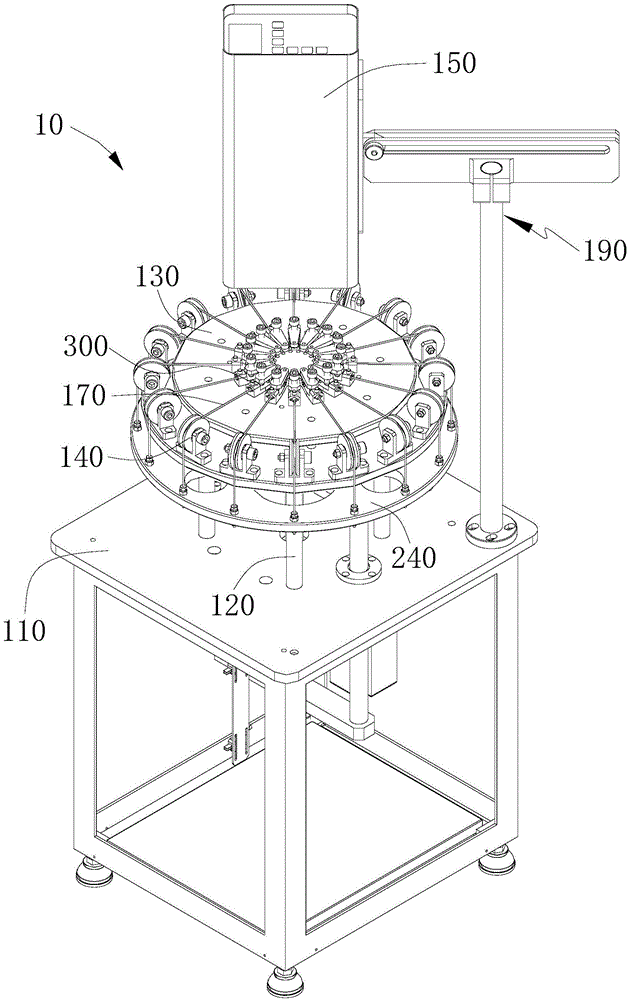

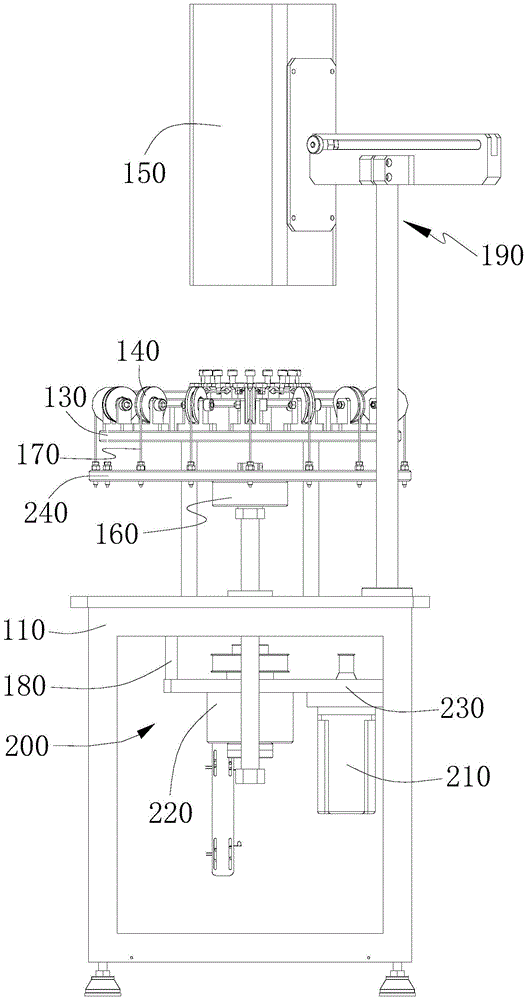

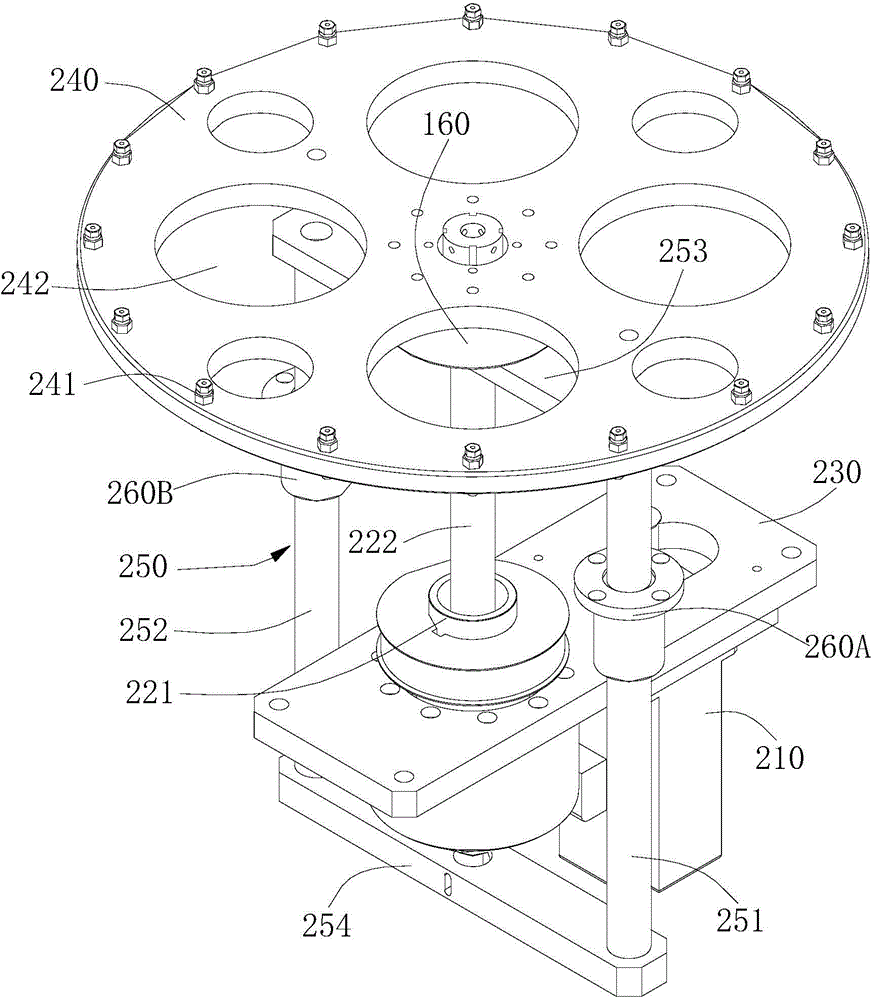

[0031] like figure 1 As shown, it is a schematic structural view of a multiaxial tensile testing machine 10 of a preferred embodiment of the present invention, figure 2 for figure 1 A side view of the multiaxial tensile testing machine 10 shown in .

[0032] The multi-axis tensile testing machine 10 includes: a mounting table 110, a support portion 120, a storage plate 130, several fixed pulleys 140, a laser extensometer 150, a lifting mechanism 200, a force sensor 160, several clamping parts 300 and several steel rods. Cable 170.

[0033] The support part 120 is fixed on the installation platform 110, and the storage board 130 is fixed on the support part 120. In the present embodiment, the support part 120 is a rod-shaped structure, and there are multiple support parts 120. In this way, the storage board 130 is fixed on multiple supports. On the part 120, prevent the storage board 130 from tilting due to excessive force on the storage board 130, so as to increase the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com