Detection apparatus of tool escape groove and detection method thereof

A detection device and tool relief technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of short service life, low rib strength, fracture, etc., to improve the pass rate and service life, accurate measurement results, and measurement results accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

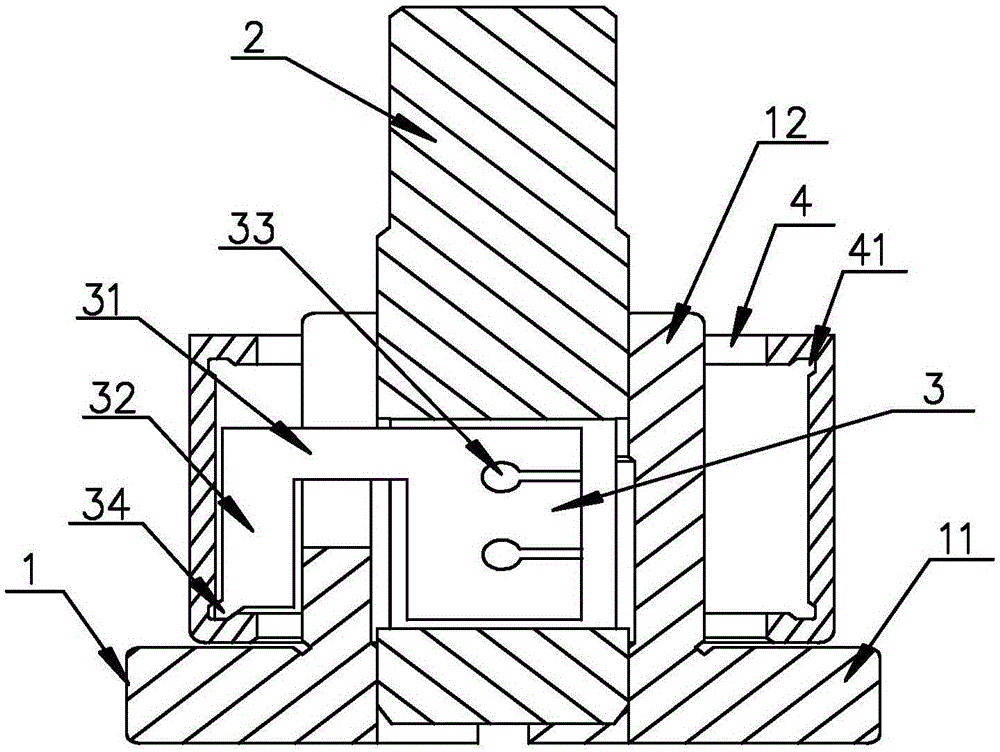

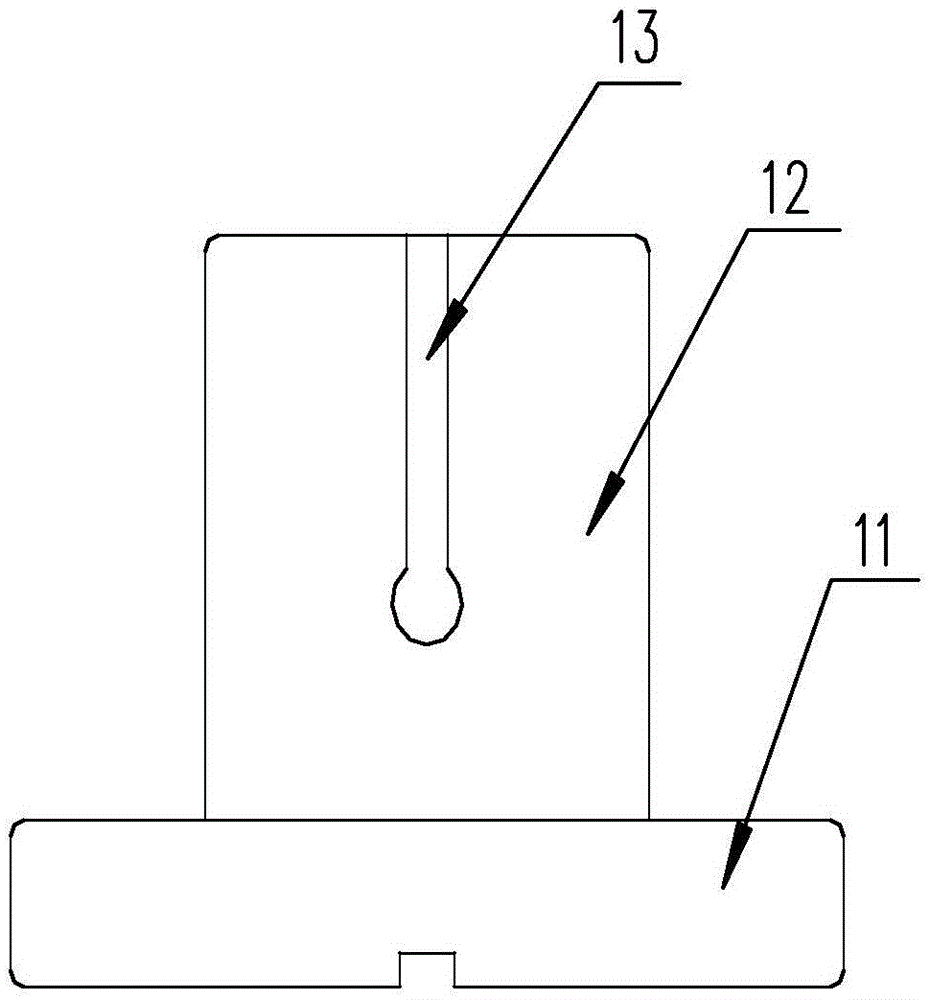

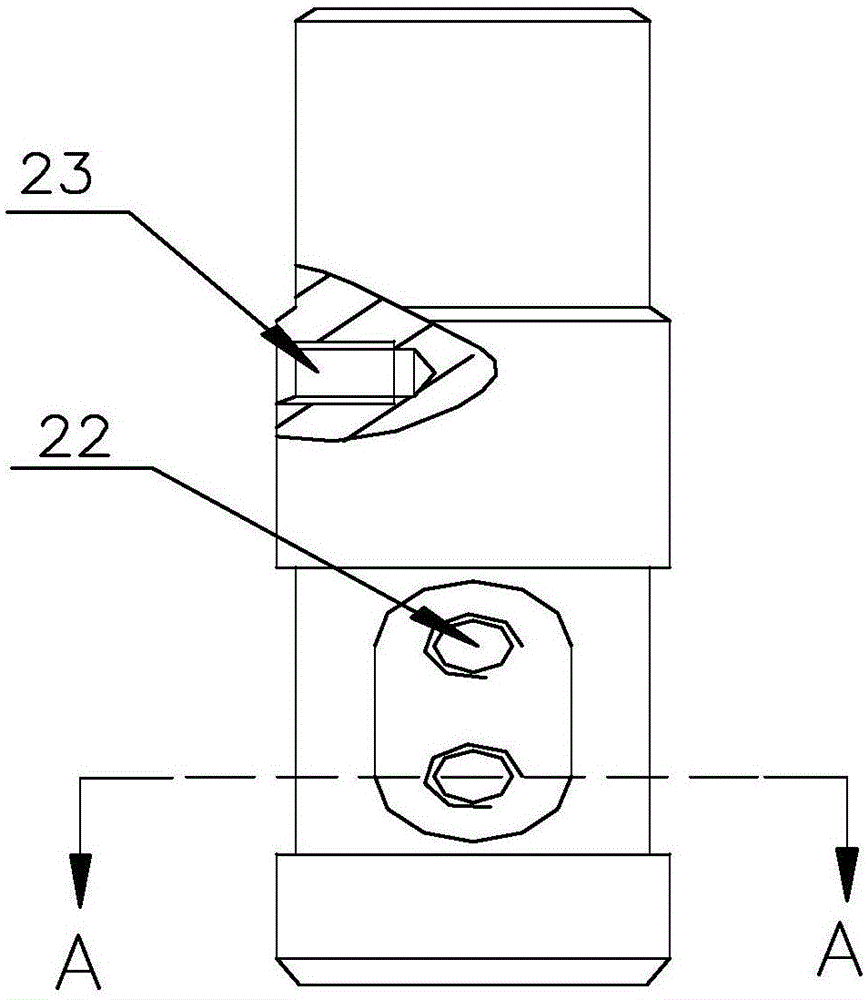

[0032] Such as figure 1 As shown, a detection device for tool undercut, the detection device includes a base 1, a mandrel 2, a detection plate 3 and an altimeter, the base 1 is a sleeve 12 with a flange 11, and the flange 11 is positioned at one end of sleeve 12, and described sleeve 12 is a hollow cylinder; Described mandrel 2 is arranged in sleeve 12, and the outside of described mandrel 2 and the inner side of sleeve 12 are provided with the guide rail ( not shown in the figure). The detection board 3 is "L" shaped and includes a horizontal plate 31 and a vertical plate 32, the horizontal plate 31 is provided with two fixing holes 33, the vertical plate 32 is located outside the sleeve 12, and the vertical plate 32 The ends are provided with bevelled angles 34 . The shape of the measuring angle 34 is the same as that of the undercut 41 , and the inclination angle of the angle measuring 34 is the same as that of the undercut 41 . The present invention adopts the inclined ...

Embodiment 2

[0041] For the case where the shape of the undercut is arc-shaped or other bottom surfaces are non-planar, when measuring, the same parts as in Embodiment 1 will not be repeated, and the difference is:

[0042] The step (2) is: moving the mandrel up and down, driving the detection plate, so that the bottom surface of the angle measurement is offset against the bottom surface of the undercut, and then moving the workpiece to be inspected, so that the angle measurement surface is offset against the undercut surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com