Mixed-flow-channel double-effect solar heat collection plate core and heat collector

A technology of solar heat collecting plate and heat collecting plate core, which is applied in the direction of solar thermal power generation, solar thermal device, heating device, etc., which can solve the problem that the heat energy of air heat collecting system cannot be utilized in summer, increase system investment and operating cost, and reduce solar energy. Use efficiency and other issues to achieve the effect of improving the effective utilization rate, enhancing the heating effect, and solving the effect of freezing and antifreezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

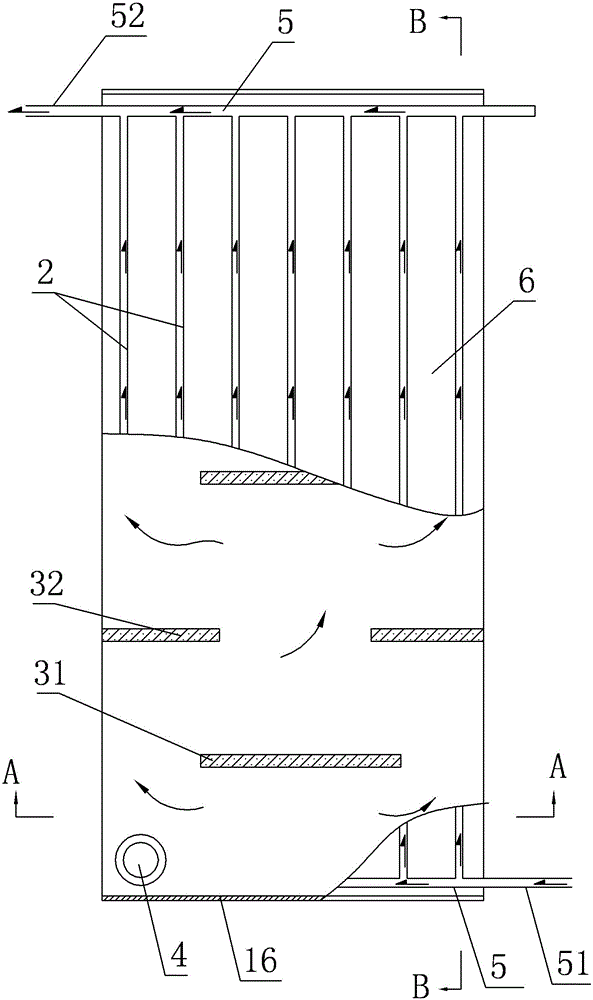

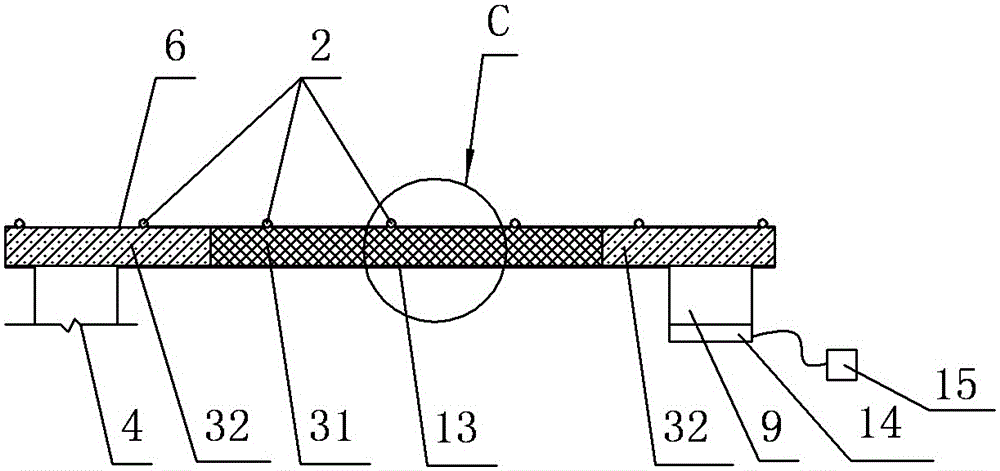

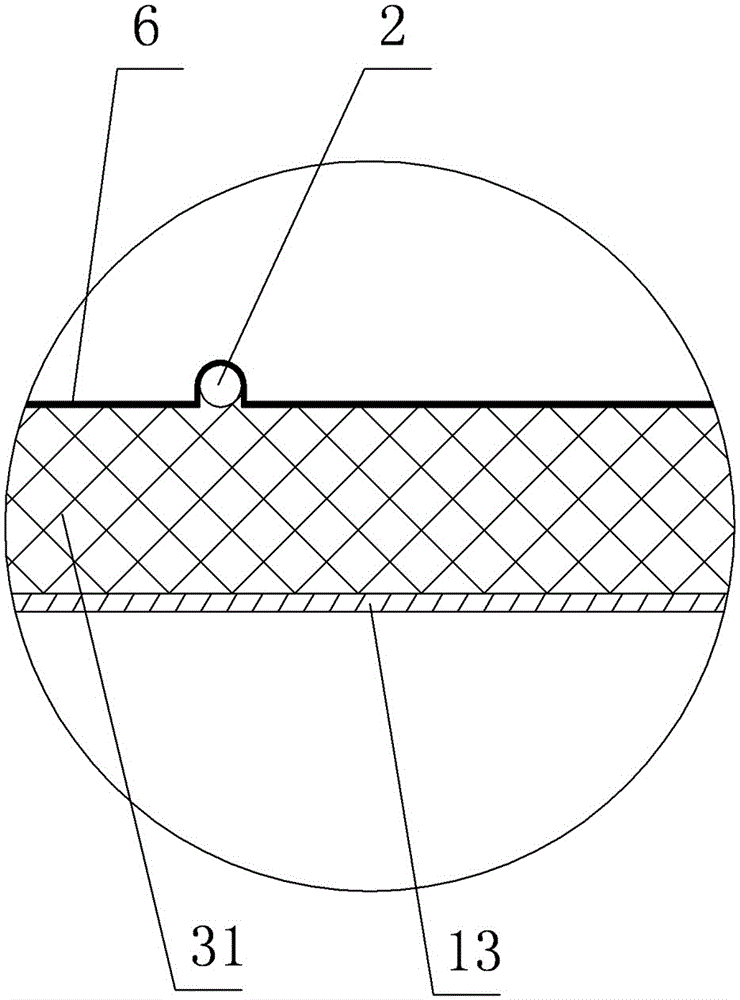

[0031] Mixed channel double-effect solar heat collector core, its structure is as follows Figure 1~5 As shown, it includes end faces 16 located at both ends of the plate core, a heat absorbing plate 6 is arranged between the two end faces 16, a bottom plate 13 is arranged below the heat absorbing plate 6, and the space between the heat absorbing plate 6, the bottom plate 13 and the end faces 16 The cavity is a ventilation layer 12, a cylindrical air inlet pipe 4 and a cylindrical air outlet pipe 9 are arranged at the diagonal position of the bottom plate 13, and an automatic damper 14 is arranged on the air outlet pipe 9, and the automatic damper 14 is connected with a controller 15; There is a U-shaped groove on the back of the plate 6, and the U-shaped groove is wrapped with a vertically arranged liquid flow channel branch pipe 2, and the two ends of the branch pipe 2 are connected with a horizontal liquid flow channel main pipe 5 that is set in the heat-absorbing plate 6 an...

Embodiment 2

[0036] Mixed channel double-effect solar heat collector core, its structure is as follows Figure 8 As shown, it includes end faces 16 located at both ends of the plate core, a heat absorbing plate 6 is arranged between the two end faces 16, a bottom plate 13 is arranged below the heat absorbing plate 6, and the space between the heat absorbing plate 6, the bottom plate 13 and the end faces 16 The cavity is a ventilation layer 12, and the two end faces 16 are provided with a rectangular air inlet pipe 4 and a rectangular air outlet pipe 9, and the width b of the air inlet pipe 4 and the air outlet pipe 9 is greater than that of the heat collecting board core. One-half, connect circular transition pipe 18 on the rectangular parallelepiped air outlet pipe 9, the side wall of transition pipe 18 is provided with the opening that is consistent with the outlet size of rectangular parallelepiped air outlet pipe 9, and rectangular parallelepiped air outlet pipe 9 inserts In the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com