Highly-efficient cotton fluffer

A kind of popping machine and high-efficiency technology, which is applied in the direction of fiber opening and cleaning machines, tooth-shaped tools, etc., can solve the problems of inability to meet the requirements of cotton looseness, insufficient cotton supply, and the need for more labor, so as to achieve flexible operation of the equipment Stable, self-adjusting and soft, ensuring clean and hygienic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

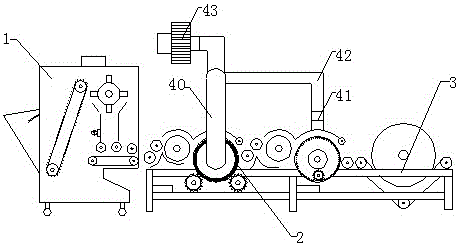

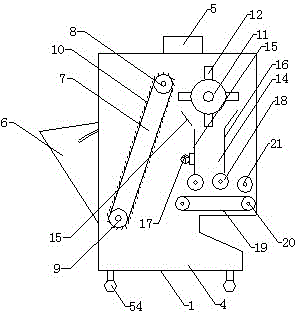

[0029] Such as figure 1 -shown in 6: a kind of high-efficiency popping machine, including automatic cotton feeding device 1, carding device 2 and cotton receiving device 3, described automatic cotton feeding device 1 includes organic casing 4, described casing 4 The top is equipped with a driving motor A5, and the left side of the casing 4 is provided with a cotton feeding port 6, and the inside of the casing 4 is provided with a cotton guiding device 7 obliquely at the cotton feeding port 6, and the cotton guiding device 7 is arranged on the inside of the casing 4. The device 7 is composed of an upper roller 8, a lower roller 9 and a conveyor belt 10. The inside of the casing 4 is provided with a cotton pulling roller 11 at the top position of the cotton guide device 7, and the cotton pulling roller 11 is provided with a cotton pulling roller 11. Teeth 12, a cotton guide plate 13 is provided below the cotton picking roller 11, a cotton storage box 14 is provided below the cot...

Embodiment 2

[0036] Such as figure 1 Shown in -7, a kind of high-efficiency popping machine includes automatic cotton feeding device 1, carding device 2 and cotton receiving device 3, and described automatic cotton feeding device 1 includes organic casing 4, and described casing 4 The top is equipped with a driving motor A5, and the left side of the casing 4 is provided with a cotton feeding port 6, and the inside of the casing 4 is provided with a cotton guiding device 7 obliquely at the cotton feeding port 6, and the cotton guiding device 7 is arranged on the inside of the casing 4. The device 7 is composed of an upper roller 8, a lower roller 9 and a conveyor belt 10. The inside of the casing 4 is provided with a cotton pulling roller 11 at the top position of the cotton guide device 7, and the cotton pulling roller 11 is provided with a cotton pulling roller 11. Teeth 12, a cotton guide plate 13 is provided below the cotton picking roller 11, a cotton storage box 14 is provided below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com