A kind of separator for seed cotton

A technology of separator and seed cotton, which is applied in textiles and papermaking, mechanical treatment, fiber treatment, etc. It can solve the problems that the output cannot meet the market demand, the structure limitation of the fixed mesh separator, and the inability to discharge impurities, etc., and achieve good impurity removal effect, Easy to apply and popularize, with remarkable beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

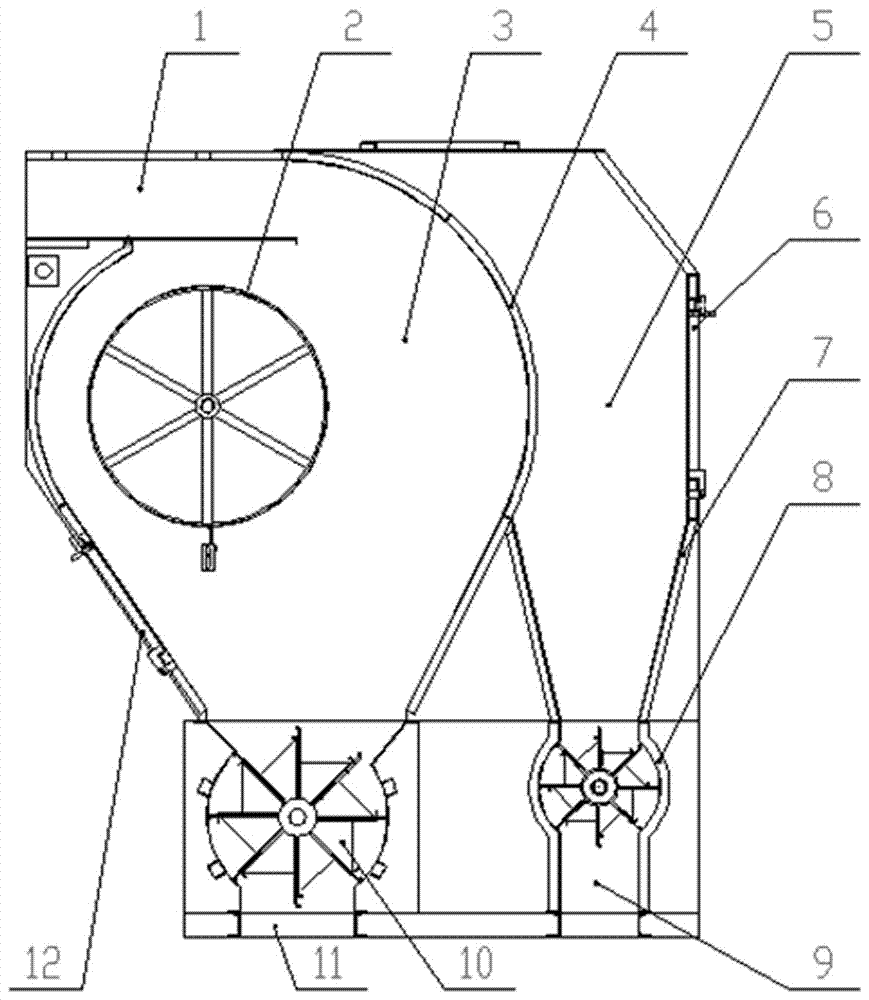

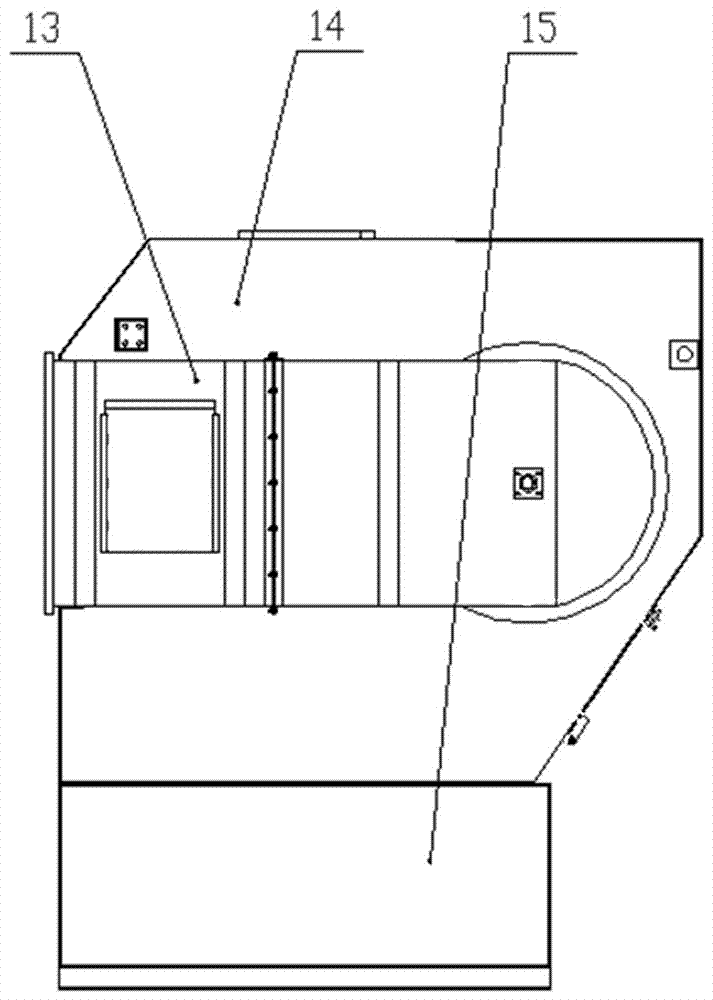

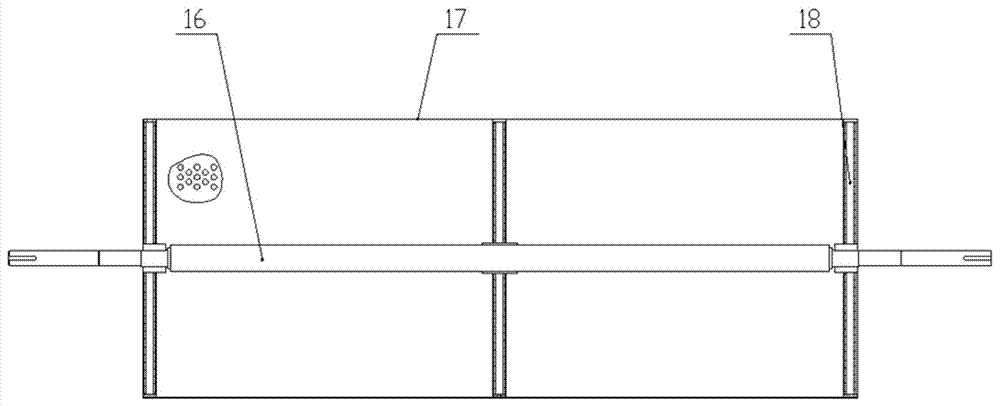

[0019] Such as figure 1 and figure 2 As shown, the sectional structure schematic diagram and the external structure schematic diagram of the seed cotton decontamination separator of the present invention are respectively provided, which include a feed bin 3, an impurity settling bin 5, a seed cotton feed channel 1, a transfer dust cage 2, Suction duct 13, miscellaneous orifice plate 4, miscellaneous wind shelter valve 8, impurity outlet 9, unloading wind shelter valve 10, and seed cotton discharge port 11 are formed. The shown seed cotton feeding channel 1 is located at the upper part of the feeding bin 3, and the seed cotton enters the feeding bin 3 through the seed cotton feeding bin channel 1, and the transfer dust cage 2 is arranged in the feeding bin 3, and one or both ends thereof are connected There is a suction duct 13, under the suction nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com