A kind of micro-alloyed 25cr35ninb alloy steel for ethylene cracking furnace tube

An ethylene cracking furnace and micro-alloying technology, which is applied in the field of ethylene cracking furnace tube materials, can solve the problems affecting the long-term safe operation of the device and the poor quality stability of the furnace tube, so as to ensure the long-term safe operation and improve the high temperature lasting fracture time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

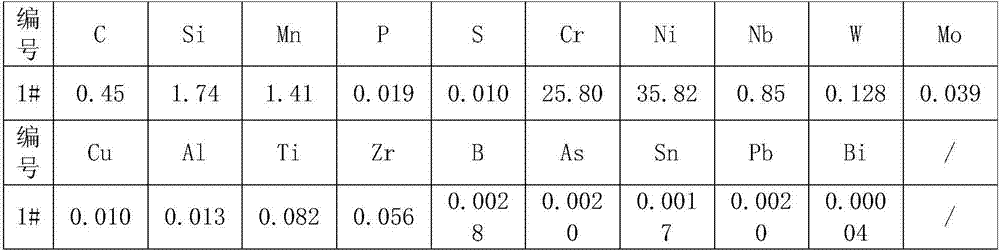

[0056] A microalloyed 25Cr35NiNb alloy steel for ethylene cracking furnace tubes, the chemical composition of which is shown in Table 1.

[0057] Table 1 Chemical composition of microalloyed 25Cr35NiNb alloy steel for ethylene cracking furnace tubes

[0058]

[0059] Note: The unit is mass percent.

[0060] After testing, the microalloyed 25Cr35NiNb furnace tube in this embodiment is etched by aqua regia, and the columnar crystals account for 89% of the wall thickness. After electrolytic etching with a volume fraction of 10% oxalic acid aqueous solution, its grain size grade is Level 5.2.

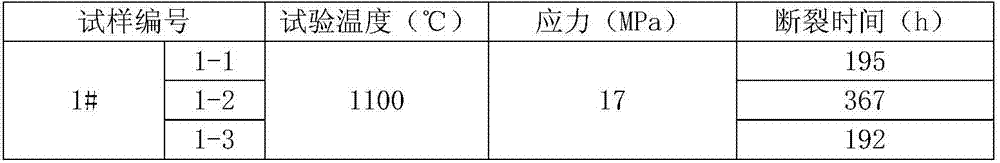

[0061] For the microalloyed 25Cr35NiNb furnace tube sample prepared with the ratio in Table 1, the high temperature endurance strength test was carried out three times under the test conditions of 1100 ° C and 17 MPa, and the test results are shown in Table 2.

[0062] Table 2 High temperature durability test results of microalloyed 25Cr35NiNb furnace tube

[0063]

[0064] It can ...

Embodiment 2

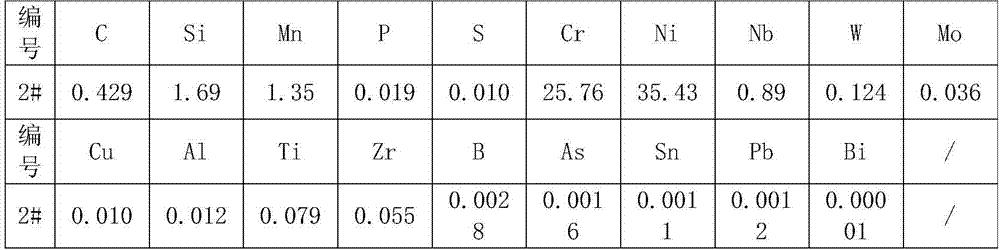

[0066] A microalloyed 25Cr35NiNb alloy steel for ethylene cracking furnace tubes, the chemical composition of which is shown in Table 3.

[0067] Table 3 Chemical composition of microalloyed 25Cr35NiNb alloy steel for ethylene cracking furnace tubes

[0068]

[0069] Note: The unit is mass percent.

[0070] After testing, the microalloyed 25Cr35NiNb furnace tube in this embodiment is etched by aqua regia, and the columnar crystals account for 100% of the wall thickness. After electrolytic etching with a volume fraction of 10% oxalic acid aqueous solution, its grain size grade is Level 5.5.

[0071] For the microalloyed 25Cr35NiNb furnace tube sample prepared in the ratio in Table 3, the high temperature endurance strength test was carried out three times under the test conditions of 1100 ° C and 17 MPa, and the test results are shown in Table 4.

[0072] Table 4 High temperature endurance test results of microalloyed 25Cr35NiNb furnace tube

[0073]

[0074] It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com