A kind of microalloyed 35cr45ninb alloy steel for ethylene cracking furnace tube

An ethylene cracking furnace and micro-alloying technology, which is applied in the field of ethylene cracking furnace tube materials, can solve the problems affecting the long-term safe operation of the device and poor quality stability of the furnace tube, so as to ensure long-term safe operation and improve the high-temperature durable fracture time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

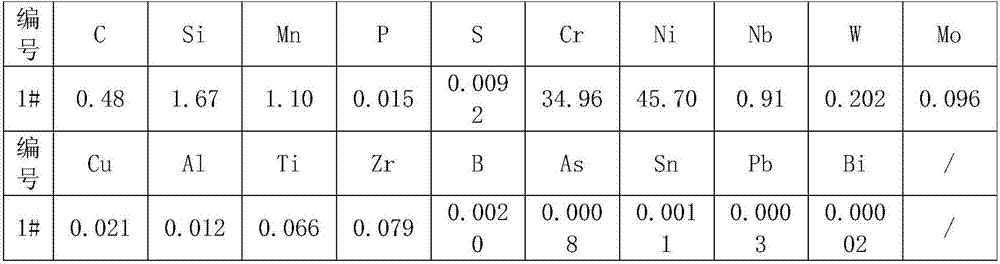

[0056] A microalloyed 35Cr45NiNb alloy steel for ethylene cracking furnace tubes, the chemical composition of which is shown in Table 1.

[0057] Table 1 Chemical composition of microalloyed 35Cr45NiNb alloy steel for ethylene cracking furnace tubes

[0058]

[0059] Note: The unit is mass percent.

[0060] After testing, the microalloyed 25Cr35NiNb furnace tube in this embodiment is etched by aqua regia, and the columnar crystals account for 100% of the wall thickness. After electrolytic etching with a volume fraction of 10% oxalic acid aqueous solution, its grain size grade is Level 5.8.

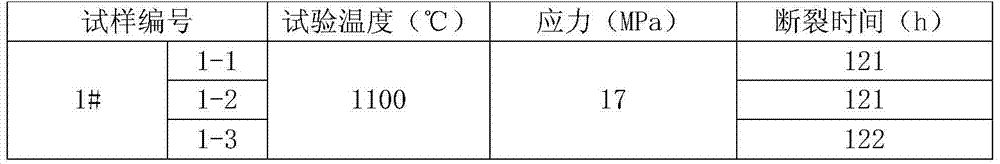

[0061] The 35Cr45NiNb+ microalloyed furnace tube samples made with the ratio in Table 1 were subjected to three high-temperature endurance strength tests under the test conditions of 1100 °C and 17 MPa, and the test results are shown in Table 2.

[0062] Table 2 High temperature durability test results of microalloyed 35Cr45NiNb furnace tube

[0063]

[0064] It can be seen from t...

Embodiment 2

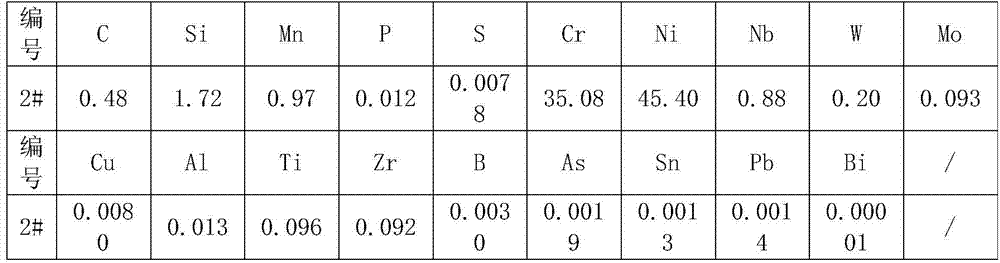

[0066] The chemical composition of a microalloyed 35Cr45NiNb alloy steel for ethylene cracking furnace tubes is shown in Table 3.

[0067] Table 3 Chemical composition of microalloyed 35Cr45NiNb alloy steel for ethylene cracking furnace tubes

[0068]

[0069] Note: The unit is mass percent.

[0070] After testing, the microalloyed 25Cr35NiNb furnace tube in this embodiment is etched by aqua regia, and the columnar crystals account for 100% of the wall thickness. After electrolytic etching with a volume fraction of 10% oxalic acid aqueous solution, its grain size grade is Level 5.0.

[0071] The 35Cr45NiNb+microalloyed furnace tube samples made with the ratios in Table 3 were subjected to three high-temperature endurance strength tests under the test conditions of 1100°C and 17MPa, and the test results are shown in Table 4.

[0072] Table 4 35Cr45NiNb+microalloyed furnace tube high temperature durability test results

[0073]

[0074] It can be seen from the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com