Novel support structure for PVC roof

A new type of bracket and rectangular bracket technology, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules and other directions, can solve the problems of fixing photovoltaic modules and other problems, and solve the problems of bearing and long-term reliability, easy installation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

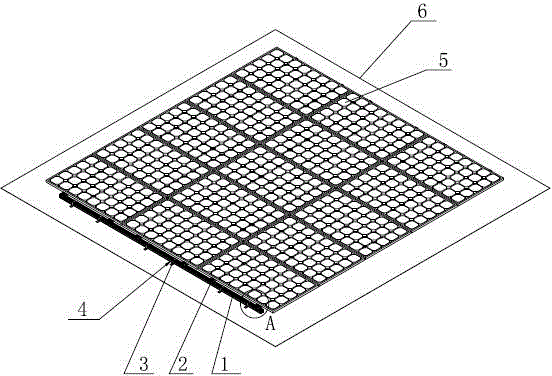

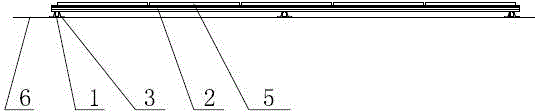

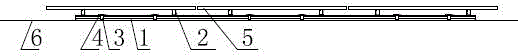

[0025] like figure 1 , figure 2 and image 3 As shown, firstly, the bottom beams 1 and purlins 2 are combined and arranged to form a 3*5 rectangular support, wherein there are three bottom beams 1, and each bottom beam 1 plays a supporting role. There are six purlins 2 , and each purlin 2 is used to fix the photovoltaic modules 5 . In order to prevent the displacement of the bracket and reduce the deformation of the fixing material, a plurality of fixing parts 4 are installed on the bottom beam 1. Since the second upper transverse plate 402 on the fixing parts 4 and the upper surface of the bottom beam 1 form a cavity, the cavity is used for Install the first upper horizontal plate 301 of the fixing bar 3, after welding the first lower horizontal plate 303 at both ends of the fixing bar 3 to the roof 6 during installation, and then connect the second lower horizontal plate 401 at both ends of the fixing member 4 to the bottom beam 1. After welding, the second upper horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com