Strong-inhibition anticaving drilling fluid and application thereof

A drilling fluid and strong suppression technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as difficult control of rheology, poor thermal stability, and easy hydration of shale formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

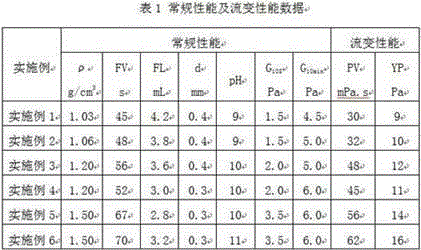

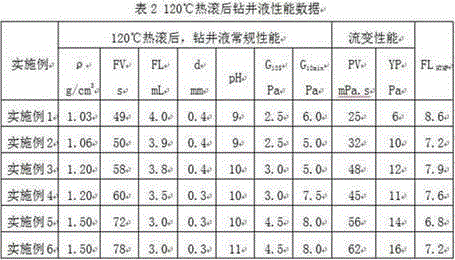

Embodiment 1

[0034] Add 1000 parts of water, 5 parts of soda ash, 5 parts of alkali, and 20 parts of bentonite for drilling fluid into the mud cup at a speed of 500 r / min in parts by weight, and pre-hydrate for 24 hours after dispersing evenly. Add 5 parts of cross-linked starch FLOTROL, 5 parts of xanthan gum, 5 parts of chemical well wall stabilizer ZK-303, 10 parts of plugging agent while drilling, and 10 parts of strong coating inhibitor PLUS into the prehydrated bentonite slurry -L, 5 parts of shale stabilizer HT-201, 5 parts of modified graphite lubricant, fully stir until each reagent is evenly dispersed, then add another, and adjust the pH to 9 with saturated sodium carbonate solution.

Embodiment 2

[0036] Add 1,000 parts of water, 10 parts of soda ash, 10 parts of alkali, and 30 parts of bentonite for drilling fluid into the mud cup at a speed of 500 r / min in parts by weight. After uniform dispersion, pre-hydrate for 24 hours. Add 10 parts of high temperature resistant starch FLO-HT, 10 parts of xanthan gum, 10 parts of potassium chloride, 10 parts of nanoemulsion blocking agent, 10 parts of strong coating inhibitor PLUS-L, 5 parts of shale stabilizer HT-201, 5 parts of liquid lubricant RH-2, fully stir until each reagent is evenly dispersed, then add the other, and adjust the pH to 9 with potassium hydroxide saturated solution.

Embodiment 3

[0038] Add 1,000 parts of water, 10 parts of soda ash, 10 parts of alkali, and 30 parts of bentonite for drilling fluid into the mud cup at a speed of 500 r / min in parts by weight. After uniform dispersion, pre-hydrate for 24 hours. Add 10 parts of sulfonated phenolic resin SMP-1, 10 parts of high-viscosity carboxymethyl cellulose, 10 parts of potassium chloride, 10 parts of non-fluorescence anti-slump plugging agent EP, 10 parts of strong Coating inhibitor PLUS-L, 5 parts of polymer alcohol, 12 parts of liquid lubricant RH-2. Stir well until each reagent is evenly dispersed before adding another, continue to add 40 parts of sodium chloride, adjust the pH to 10 with a saturated solution of sodium carbonate, and use a density of 4.0g / cm 3 The barite is aggravated to a drilling fluid density of 1.20g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com