Easily-dispersible aluminum pigment used for ink and preparation method thereof

An easy-to-disperse aluminum pigment technology, applied in the field of aluminum pigments, can solve problems such as affecting ink adhesion, large dust, and weak solvent polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

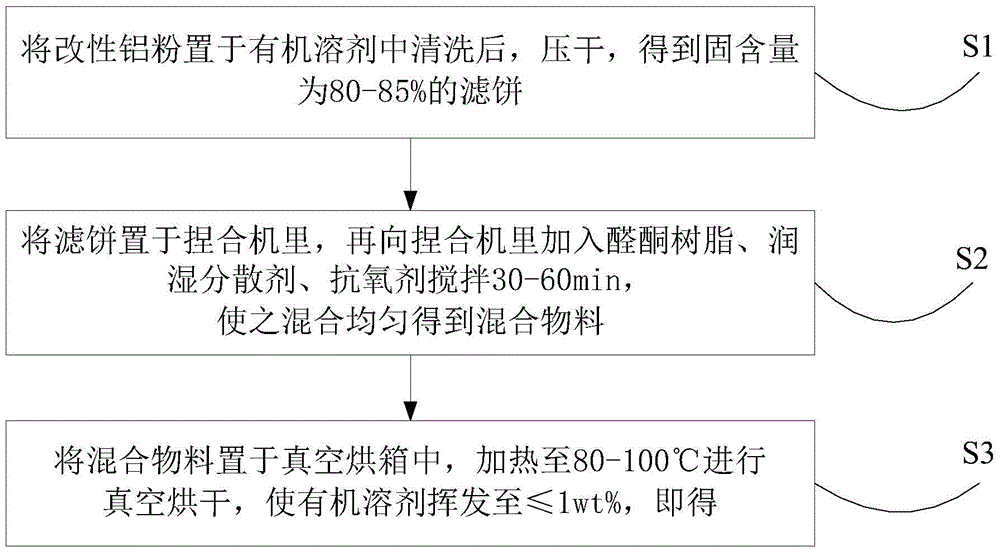

[0026] refer to figure 1 , the preparation method of a kind of printing ink that the present invention proposes is easy to disperse aluminum pigment, comprises the steps:

[0027] S1. After cleaning the modified aluminum powder in an organic solvent, press dry to obtain a filter cake with a solid content of 80-85%;

[0028] S2. Put the filter cake in a kneader, then add aldehyde and ketone resin, wetting and dispersing agent, and antioxidant into the kneader and stir for 30-60 minutes to make it evenly mixed to obtain a mixed material;

[0029] S3. Put the mixed material in a vacuum oven, heat to 80-100° C. for vacuum drying, and volatilize the organic solvent to ≤ 1 wt%.

Embodiment 1

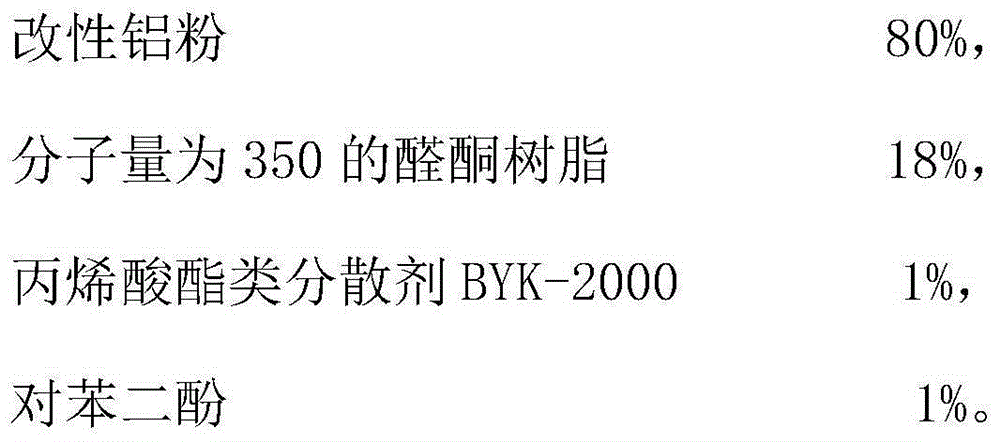

[0032] A kind of easily dispersible aluminum pigment for printing ink that the present invention proposes, its raw material comprises by weight percentage:

[0033]

[0034] Among them, the preparation method of the modified aluminum powder is as follows: put 800 mesh spherical aluminum powder and D80 in a ball mill with a ball-to-material ratio of 10:1, after ball milling for 6 hours, suction filter and dry to obtain the first material; add the first material After 3 hours of low-speed stirring in absolute ethanol, the speed of low-speed stirring is 500rpm, aging for 22 hours, and then drying to obtain the second material; based on the weight of the second material, add 2wt% polydimethylsiloxane to the second material Alkanes and 4wt% vinyltriethoxysilane were evenly mixed, then the temperature was raised to 40° C., kept for 5 hours, washed, and dried to obtain modified aluminum powder.

[0035] The preparation method of the above-mentioned ink that the present invention p...

Embodiment 2

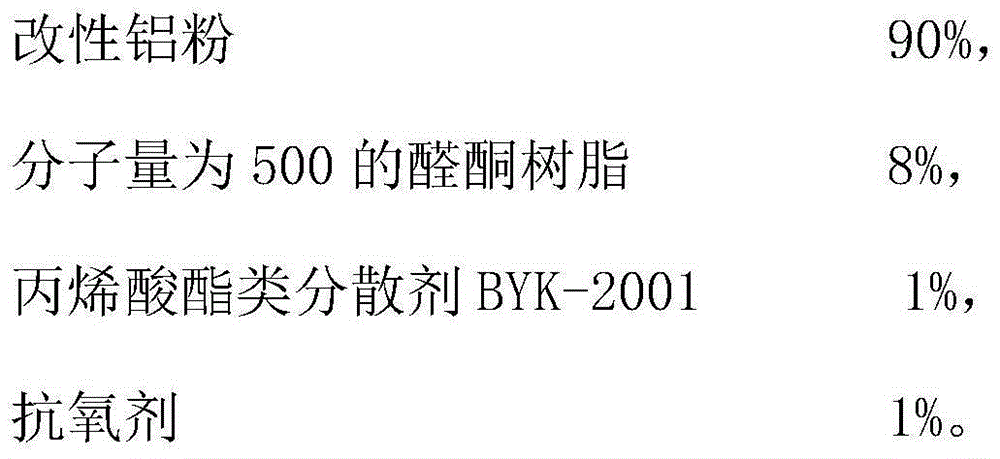

[0040] A kind of easily dispersible aluminum pigment for printing ink that the present invention proposes, its raw material comprises by weight percentage:

[0041]

[0042] Among them, the preparation method of the modified aluminum powder is as follows: put 900 mesh spherical aluminum powder and D80 in a ball mill, the ball-to-material ratio is 8:1, after ball milling for 10 hours, suction filter and dry to obtain the first material; add the first material After 2 hours of low-speed stirring in absolute ethanol, the speed of low-speed stirring is 300rpm, aging for 20 hours, and then drying to obtain the second material; based on the weight of the second material, add 3wt% polydimethylsiloxane to the second material Alkanes and 3wt% vinyltriethoxysilane were evenly mixed, heated to 50°C, kept for 3 hours, washed, and dried to obtain modified aluminum powder.

[0043] The antioxidant is a combination of catechol and hydroquinone.

[0044] The preparation method of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com