Preparing method for modified starch in glass fiber impregnating compounds

A modified starch and sizing technology, applied in the field of glass fiber yarn, can solve the problems of complex process, high raw material cost, and increased production cost, and achieve the effects of uniform distribution, good wear resistance, and reduced fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

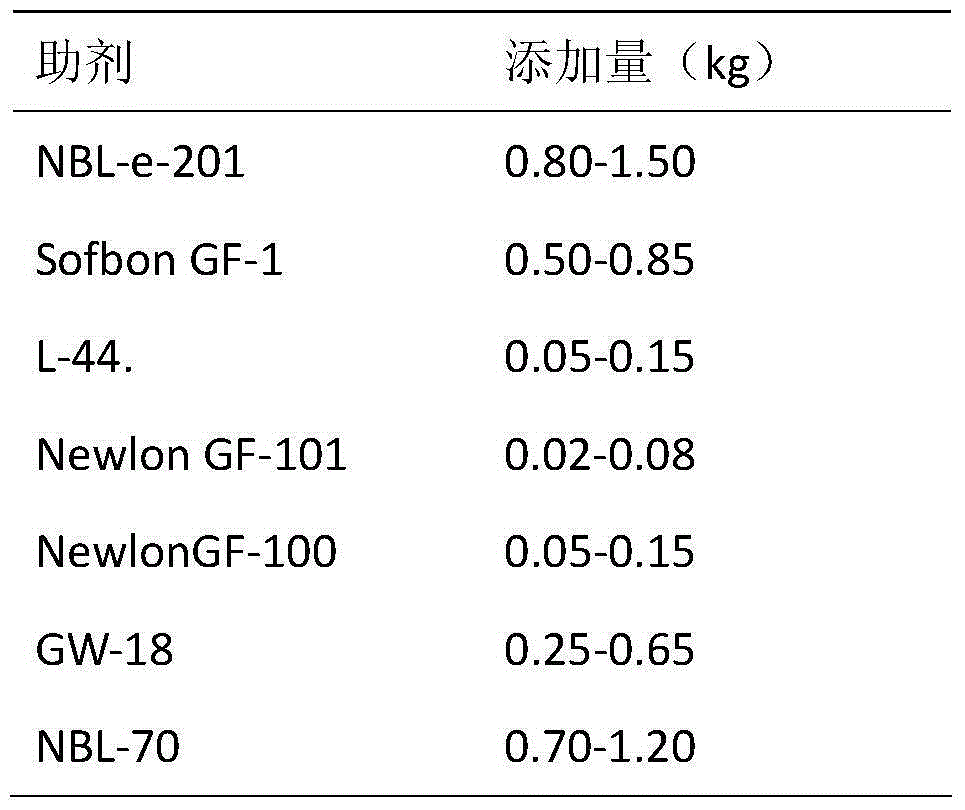

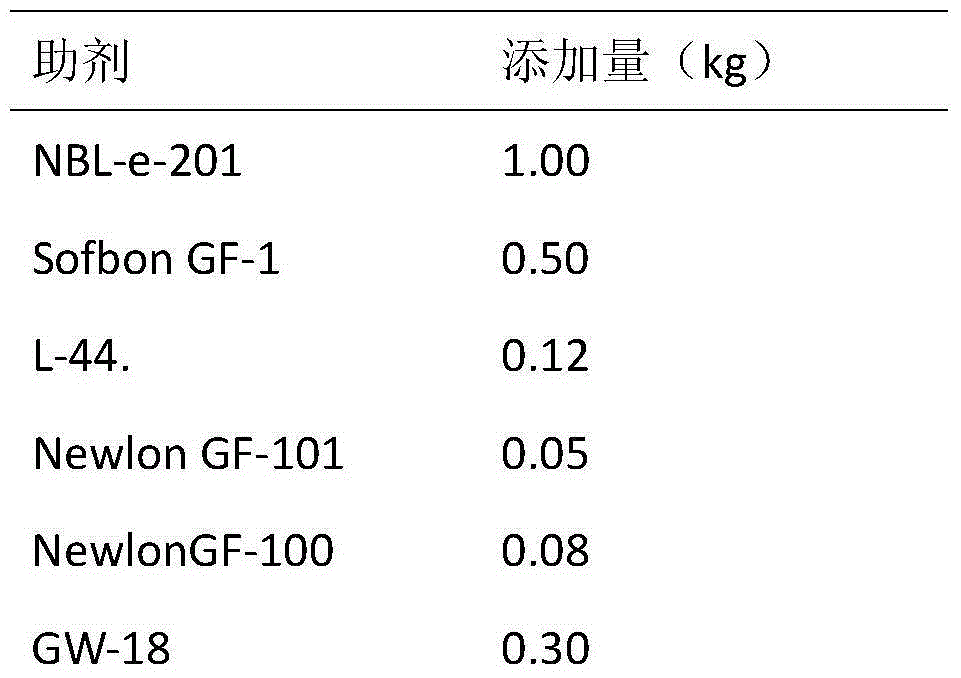

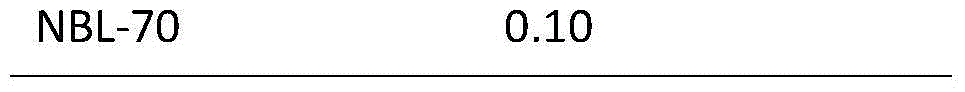

Examples

Embodiment 1

[0035] A modified starch used in glass fiber sizing agent is obtained by mixing cationic starch and amylose, and its preparation method is as follows:

[0036] (1) The cornstarch is adjusted into starch milk with a mass concentration of 35% with distilled water, and sodium sulfate equivalent to 5% of the starch mass is added to the starch milk;

[0037] (2) the pH of the NaOH solution regulating step (1) gained starch milk with 1mol / L is 10.0, adds the alkali catalyst NaOH that is equivalent to starch quality 5%, then adds the etherifying agent CHPTMA that is equivalent to starch quality 8%, in Stir and react at 40°C for 10 hours, then add 1mol / L HCl solution to adjust the pH of the starch milk to 4.0, end the reaction, and obtain the reacted starch milk;

[0038] (3) The starch milk after the reaction described in step (2) is extracted and washed 4 times with ethanol, and then washed 2 times with distilled water, and then the washed product is dried in a blast drying oven at ...

Embodiment 2

[0043] A modified starch used in glass fiber sizing agent is obtained by mixing cationic starch and amylose, and its preparation method is as follows:

[0044] (1) adjusting the pea starch with distilled water into starch milk with a mass concentration of 40%, adding sodium sulfate equivalent to 5% of the starch mass in the starch milk;

[0045] (2) the pH of the NaOH solution regulating step (1) gained starch milk with 1mol / L is 12.0, adds the alkali catalyst NaOH that is equivalent to starch quality 5%, then adds the etherifying agent CHPTMA that is equivalent to starch quality 10%, in Stir and react at 45°C for 16 hours, then add 1 mol / L HCl solution to adjust the pH of the starch milk to 5.0, end the reaction, and obtain the reacted starch milk;

[0046] (3) The starch milk after the reaction described in step (2) is extracted and washed 4 times with ethanol, and then washed 2 times with distilled water, and then the washed product is dried in a blast drying oven at 45°C, pu...

Embodiment 3

[0077] A modified starch used in glass fiber sizing agent is obtained by mixing cationic starch and amylose, and its preparation method is as follows:

[0078] (1) adjusting the rice starch into starch milk with a mass content of 45% with distilled water, adding sodium sulfate equivalent to 5% of the starch mass in the starch milk;

[0079] (2) the pH of the NaOH solution regulating step (1) gained starch milk with 1mol / L is 12.0, adds the alkali catalyst NaOH that is equivalent to starch quality 10%, then adds the etherification agent GTA that is equivalent to starch quality 10%, in Stir and react at 45°C for 12 hours, then add 1mol / L HCl solution to adjust the pH of the starch milk to 5.0, end the reaction, and obtain the reacted starch milk;

[0080] (3) The starch milk after the reaction described in step (2) is extracted and washed 4 times with ethanol, and then washed 2 times with distilled water, and then the washed product is dried in a blast drying oven at 45°C, pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com