Automatic multi-layer conveying system

An automatic conveying and conveyor belt technology, applied in the field of conveying systems, can solve the problems of increasing operating costs, increasing transportation time, wasting energy, etc., and achieve the effects of improving cargo transportation efficiency, reducing transportation time, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

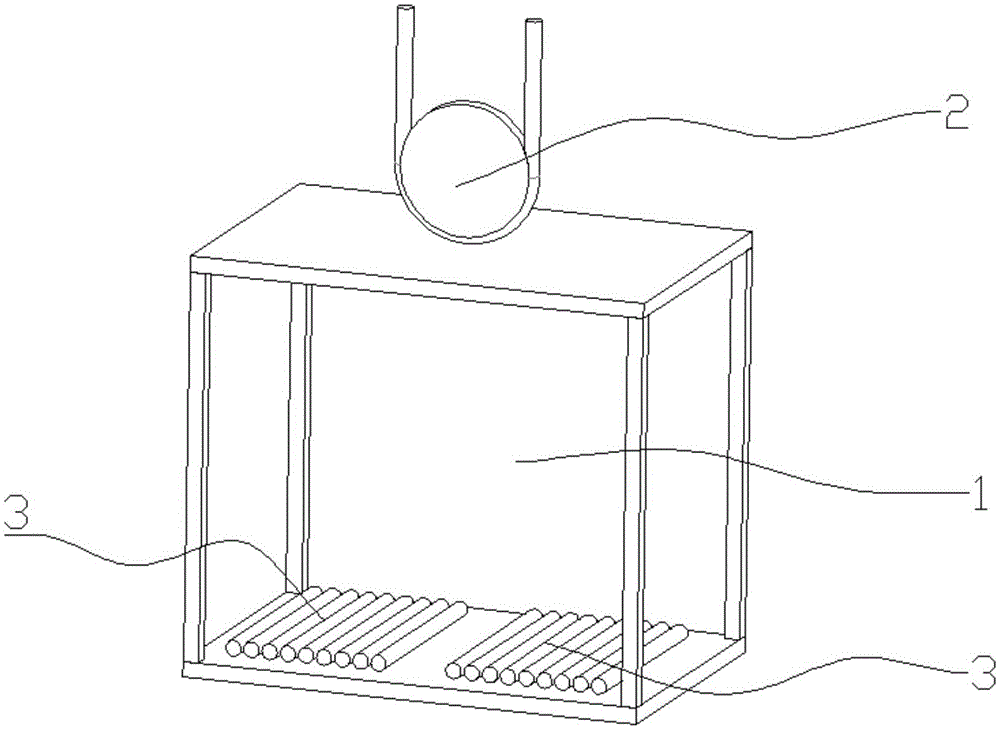

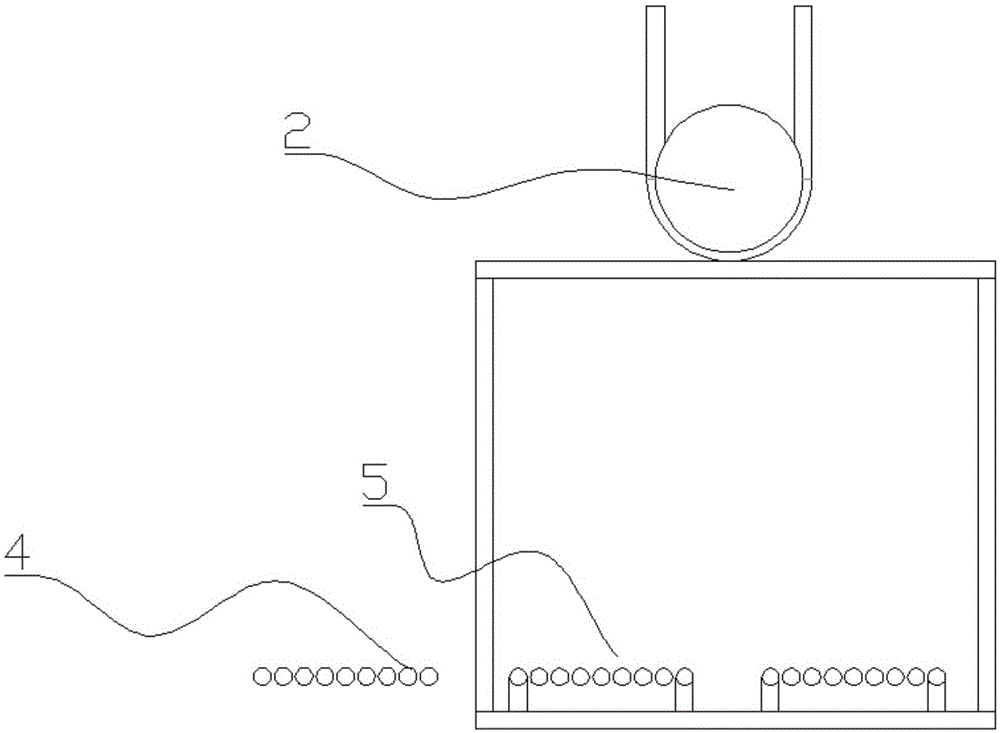

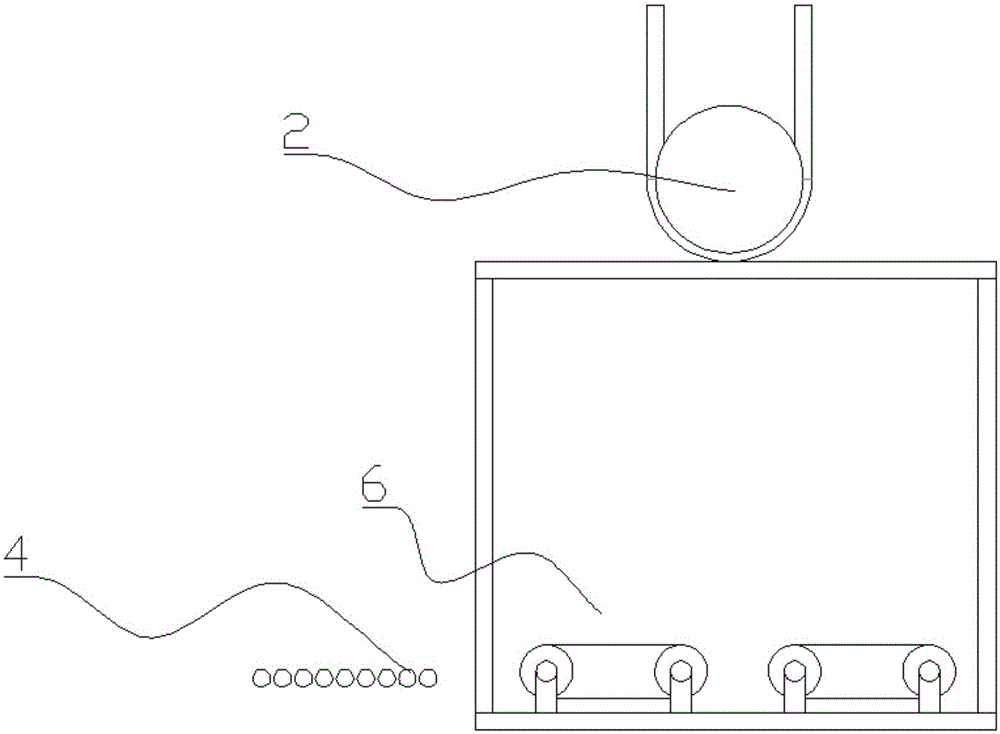

[0029] In order to achieve the purpose of the present invention, as Figure 1-4 As shown, one of the implementations is: a multi-layer automatic conveying system, including a carrying platform 1 and a lifting device 2 that drives the carrying platform up and down, and the carrying platform 1 is provided with at least two sets of cargo conveying devices 3 ; The cargo conveying devices 3 are provided with mutually independent drive units, and each set of cargo conveying devices 3 can work independently or synchronously at the same time, and the cargo conveying devices 3 can choose roller conveying devices 5 or conveyor belts Conveying device 6 or slide rail conveying device 7, lifting device 2 can choose traction device or hydraulic lifting device or cross arm lifting device or chain lifting device or rack lifting device, carrying platform 1 can choose car or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com