Swing arm type compression garbage can and method for garbage extrusion performed by means of swing arm type compression garbage can

A technology of compression box and swing arm type, which is applied in the field of swing arm type compression garbage box and its squeezed garbage, which can solve the problems that garbage trucks cannot achieve the maximum load capacity, cannot achieve solid-liquid separation, waste time, manpower, etc. Achieve good sealing, prevent garbage from rebounding, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

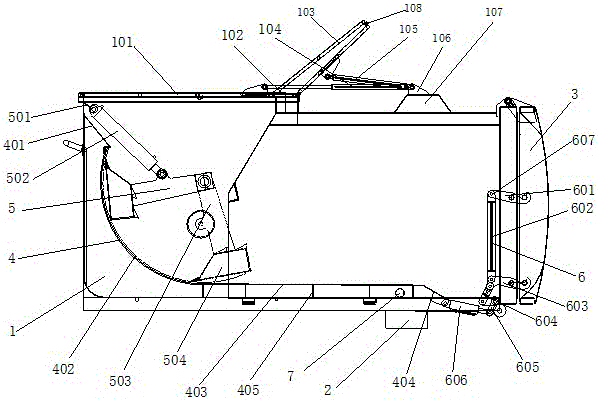

[0042] figure 1 It is a structural schematic diagram of the swing arm type compressed garbage bin of the present invention.

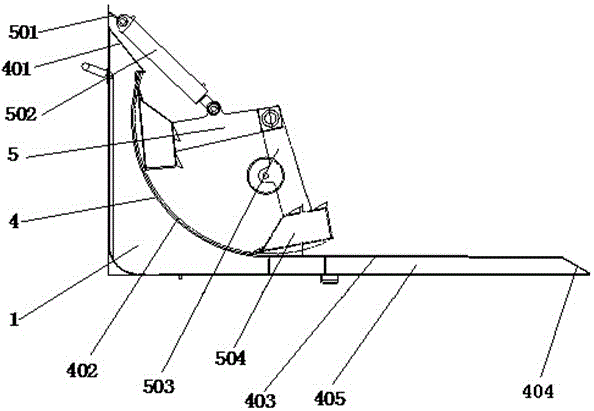

[0043] Such as figure 1As shown, the present invention provides a swing arm type compression garbage bin, comprising: a compression box body 1, a sewage tank 2 and a rear door 3; The sewage interface 7 is connected, and the rear door 3 is connected to the tail of the compression box body; the compression box body 1 is provided with a slide plate 4, a pendulum-type compression head 5 and a locking mechanism 6, and the slide plate 4 is arranged on the compression box body 1. At the bottom, the pendulum-type compression head 5 moves along the slide plate; the pendulum-type compression head 5 includes a rotating rod 501, a compression cylinder 502, a swing arm 503 and a compression push plate 504, and one end of the rotating rod 501 is installed on the body of the compression box 1 At the top corner, the other end is connected with the top of the compre...

Embodiment 2

[0045] The present invention provides a swing arm type compressed garbage box, comprising: a compression box body 1, a sewage tank 2 and a rear door 3; The back door 3 is connected to the tail of the compression box body; the inside of the compression box body 1 is provided with a slide plate 4, a pendulum-type compression head 5 and a locking mechanism 6, the slide plate 4 is arranged at the bottom of the compression box body 1, and the pendulum Type compression head 5 moves along the slide plate;

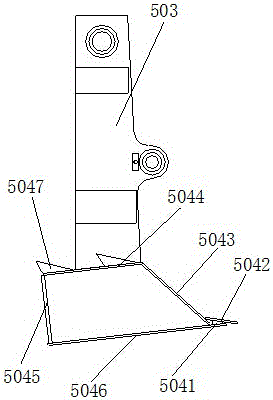

[0046] The pendulum type compression head 5 includes a rotating rod 501, a compression cylinder 502, a swing arm 503 and a compression push plate 504, and one end of the rotation rod 501 is installed at the top corner of the compression box body 1, and the other end is connected to the top of the compression cylinder 502 , the bottom end of the compression cylinder 502 is connected to the swing arm 503 , and the compression push plate 504 is installed on the bottom end of the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com