Centrifugal pump type water jetting propulsion amphibious device and work method thereof

An amphibious, water-jet propulsion technology, applied to propulsion components, ship propulsion, amphibious vehicles, etc., can solve the problems of propeller damage, high cost, scratches, etc., reduce the risk of downtime, easy maintenance, and convenient implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Centrifugal pump water jet propulsion device

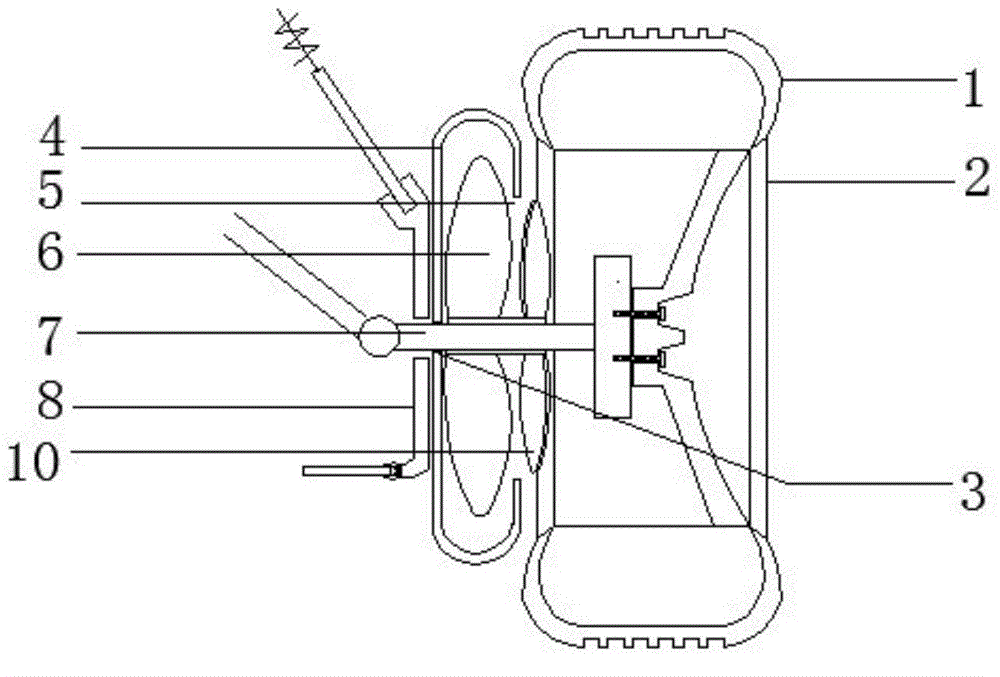

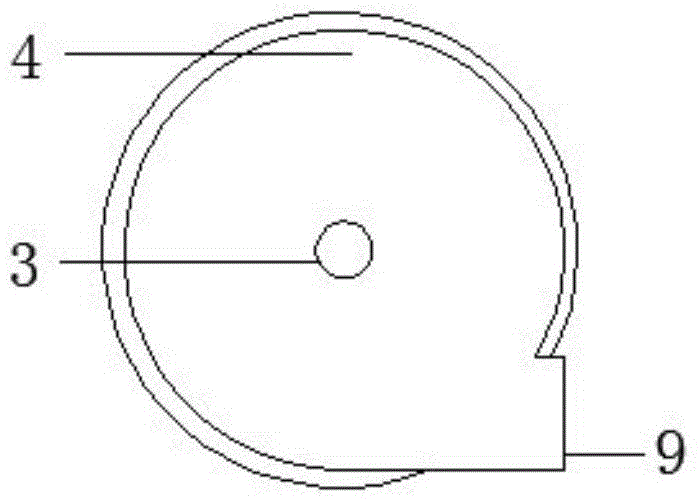

[0050] See attached figure 1 to attach Figure 4 The structure shown is attached for the convenience of explanation figure 1 The direction shown is described as an example, the right side is the outer side of the driving wheel, and the left side is the inner side of the driving wheel; a turbine 8 for installing the driving wheel is installed at the lower part of the propulsion device, and the transmission shaft 7 is installed by rotating the wheel frame. The outer end of the transmission shaft is the same as The shaft drive is equipped with a driving wheel. The driving wheel is composed of a coaxial tightly fitted hub 2 and a tire 1. The transmission shaft drives the driving wheel to rotate. The driving wheel is mainly used for driving on land.

[0051] The innovation of this device lies in:

[0052] A centrifugal pump type water jet propulsion device is installed on the transmission shaft of the driving wheel, and the w...

Embodiment 2

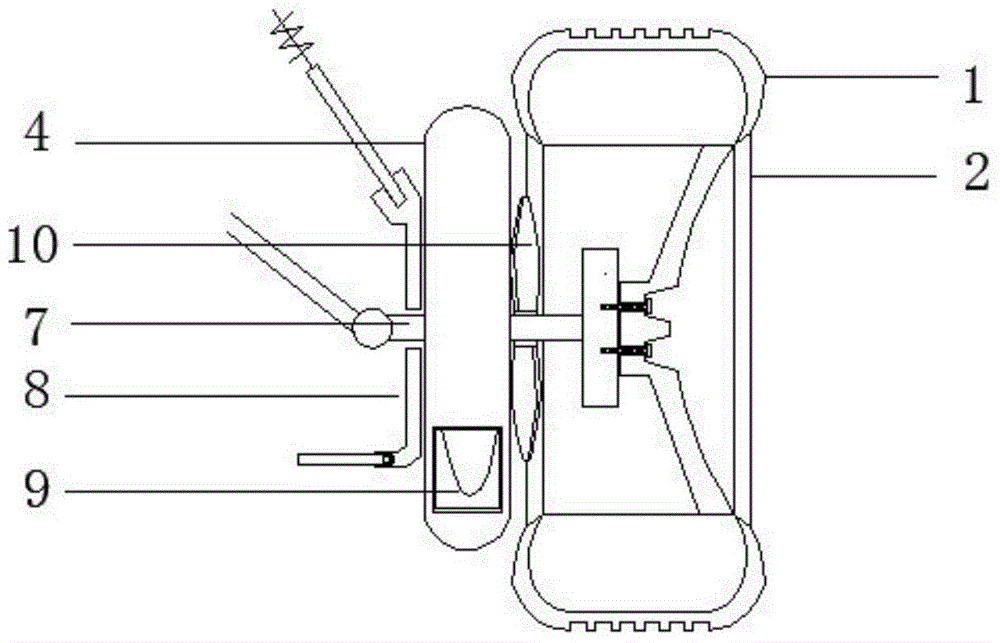

[0061] Hub type centrifugal structure amphibious water jet propulsion device

[0062] See attached Figure 5 to attach Figure 8 The structure shown, in order to facilitate the description of this embodiment with the attached Figure 5 The direction shown is described, the right side is the outside of the drive wheel, and the left side is the inside of the drive wheel; a wheel frame 8 for installing the drive wheel is installed at the bottom of the dual-purpose water jet propulsion device, and the wheel frame is rotated to install the drive shaft 7, and the drive shaft The coaxial drive at the outer end is equipped with a driving wheel. The driving wheel is composed of a coaxial tightly fitted hub 2 and a tire 1. The transmission shaft drives the driving wheel to rotate. The driving wheel is mainly used for driving on land.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com