Automatic production system of metal bucket cover

A technology of automatic production and metal barrels, which is applied in the field of metal product processing, can solve the problems of unguaranteed quality of stamping products, no identical patent technical documents found, and high labor intensity, so as to improve labor efficiency and product quality and reduce labor The effect of reducing the quantity and operation hazards and improving the product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

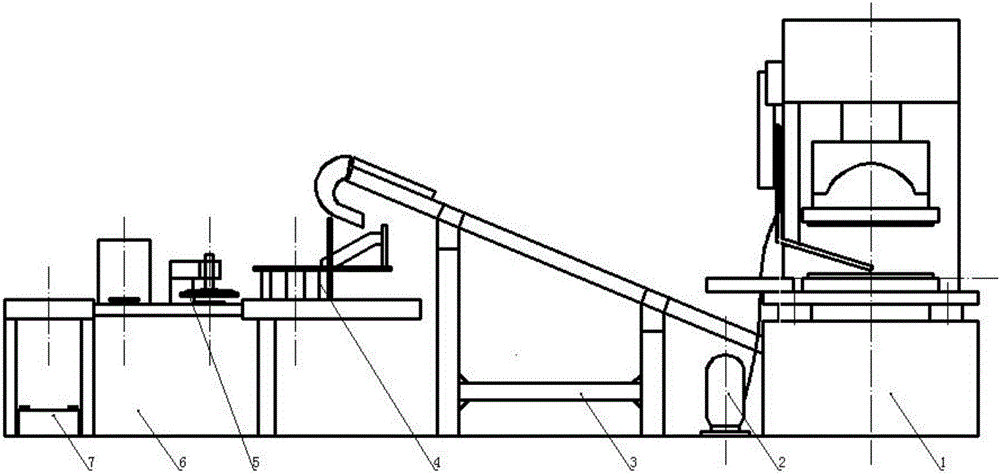

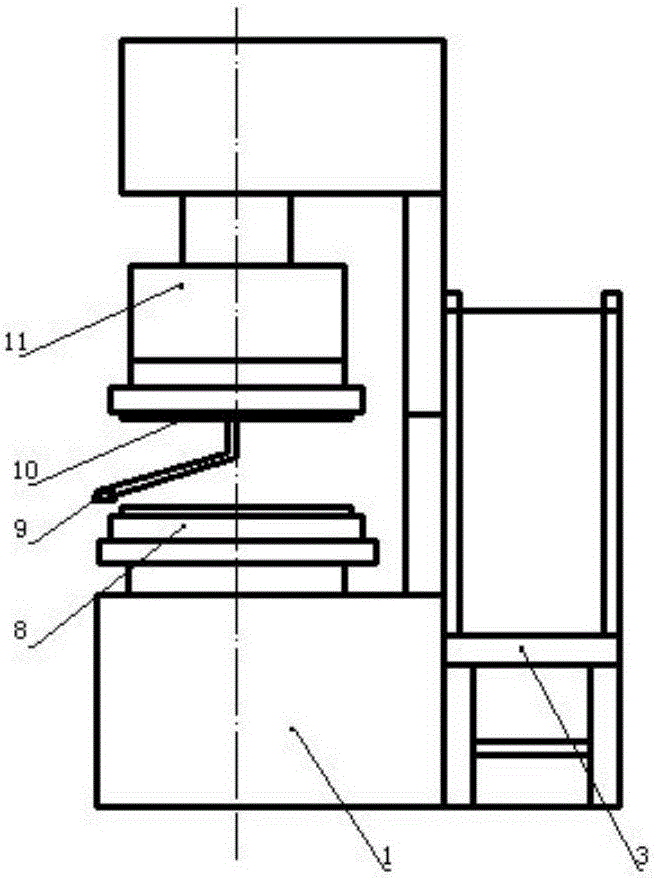

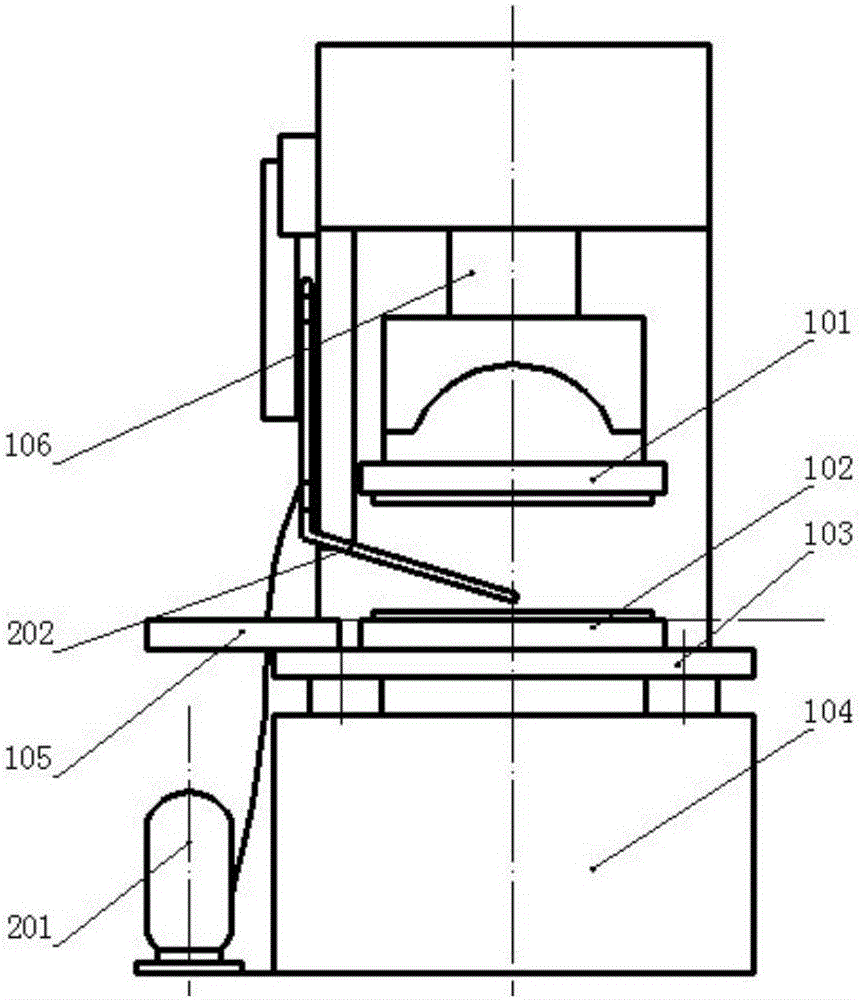

[0027] An automatic production system for metal barrel lids, including a punching machine 1, a pneumatic blowing device 2, a transmission frame 3, an electric control table 6, a limit frame 4, a molding device 5, and a discharge box 7, the punching machine, the transmission frame, The limit frame, the molding device and the discharge box are connected sequentially. In this embodiment, the right side is the input end and the left side is the output end. The output port of the punching machine is connected to the input end of the feeding frame, and the feeding frame is in order from low to high. For transmission, an electric control workbench is installed under the output end of the feeding frame. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com