Anode bar brushing equipment

An anode rod and brushing technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as affecting product quality, increasing production costs, and spilling precious metal oxides, and improving surface quality and coating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

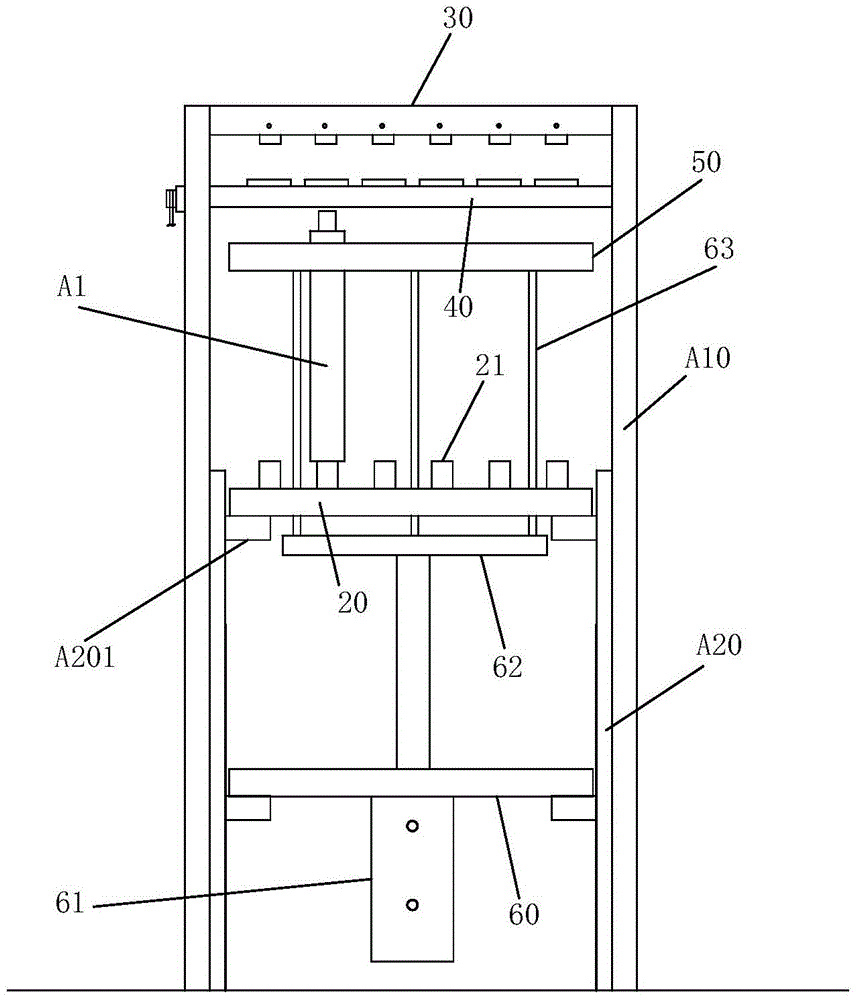

[0024] The technical scheme that the present invention takes is as figure 1 , 2 As shown in , 3 and 4, a kind of equipment for brushing anode rods includes a frame A20 and a fixing device for fixing the rods, the middle part of the frame A20 is provided with a vertically arranged bracket A10, and the rods A1 stand vertically fixed on the fixing device, the bar A1 includes the bar body A11 and the trunnion A12 provided at the upper and lower ends of the bar body A11 respectively, the fixing device includes a tooling plate 20, and the tooling plate 20 is arranged at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com