Economical and practical paint spraying rack for hydraulic cylinder

A technology of spraying racks and hydraulic cylinders, which is applied in the fields of spraying racks and hydraulic cylinders, and can solve the problems of unsightly products, increased labor costs, and low work efficiency, and achieve cost savings, simple structure, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

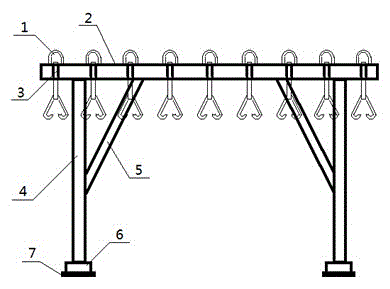

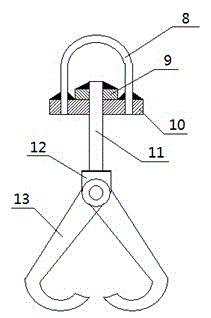

[0017] figure 1 It is a structural schematic diagram of an economical and practical hydraulic cylinder paint spraying rack in an embodiment of the present invention; the paint spraying rack is composed of a rack body and a hanger 1, the hanger 1 is placed on the rack body, and the rack body is a welded part. The main beam 2, the legs 4, the diagonal brace 5, the leg base 6 and the frame bottom plate 7 are welded from top to bottom. The structure of the hanger 1 is a lifting handle 8, a small circle from top to bottom. Shaped plate 9, large circular plate 10, round steel 11, U-shaped plate 12 and hook 13.

[0018] The economical and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com