Photovoltaic power generation greenhouse capable of adjusting light transmittance

A photovoltaic power generation greenhouse and light transmittance technology, applied in the field of photovoltaic greenhouse, can solve the problems of photovoltaic module growers having difficulty in power generation and production time, inability to adapt to adjustment, and high temperature, so as to improve land utilization, move smoothly and reliably, improve adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Traditional photovoltaic power generation greenhouses are limited by the fixed installation of photovoltaic modules, and cannot find an optimal balance between power generation and crop growth. The inventor proposed an idea after research, and designed a controllable and efficient photovoltaic power generation greenhouse from the perspective of changing the light transmittance, so as to break through the limitation bottleneck of the development of existing technologies and provide new opportunities for the development of photovoltaic power generation greenhouses. ideas and directions.

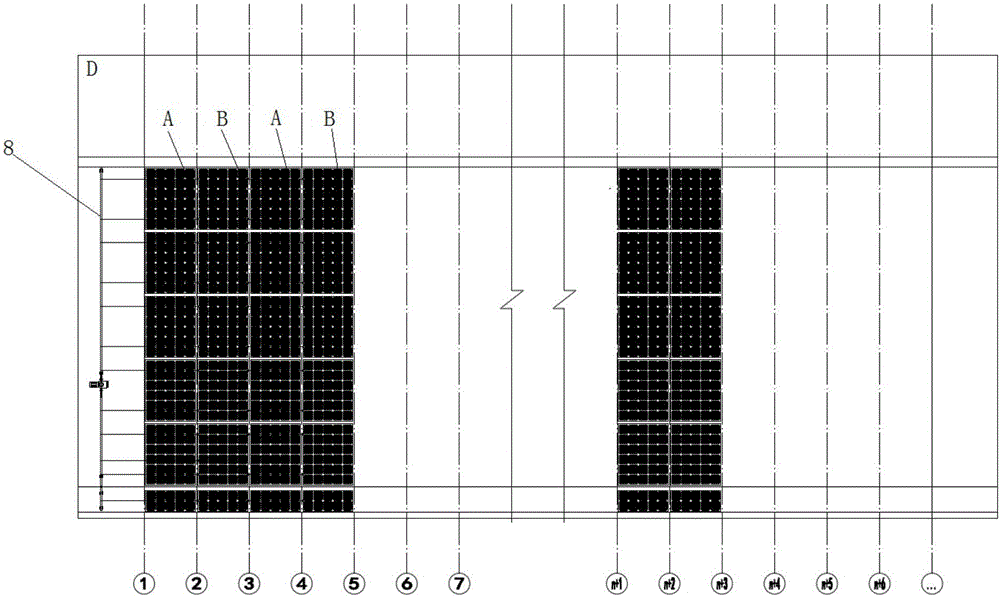

[0037] A photovoltaic power generation greenhouse with adjustable light transmittance, comprising an east gable 2, a west gable 7, a pair of side walls, and a lighting surface skeleton D installed on the top of the east gable 2, west gable 7, and side walls, the lighting surface The bottom of the framework D is provided with a lighting covering film C, and the top of the framework D on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com