A kind of characterization method of graphene

A graphene and characterization technology, applied in the field of graphene material characterization, can solve the problems of low repeatability, high cost, difficult characterization, etc., and achieve the effect of high repeatability, reduced characterization cost, and large characterization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] see figure 1 and figure 2 , the invention provides a graphene characterization method.

[0037] Firstly, a graphene single crystal grown directly on a copper substrate by chemical vapor deposition (CVD), such as figure 1 Shown is an optical microscope image of a single crystal of graphene on a copper substrate. The points pointed by the black arrows in the figure are individual graphene single crystals, including a single hexagonal graphene single crystal and two connected hexagonal graphene single crystals, which are distributed in different positions on the copper substrate and do not form continuous graphene. membrane.

[0038] Then put the graphene single crystal together with the copper substrate under it into FeCl with a mass concentration of 1g / L 3 In the solution, keep it for 1 hour, so that the Cu substrate reacts properly. If the reaction time is too short, the ideal observation morphology will not be achieved, and if the reaction time is too long, the g...

Embodiment 2

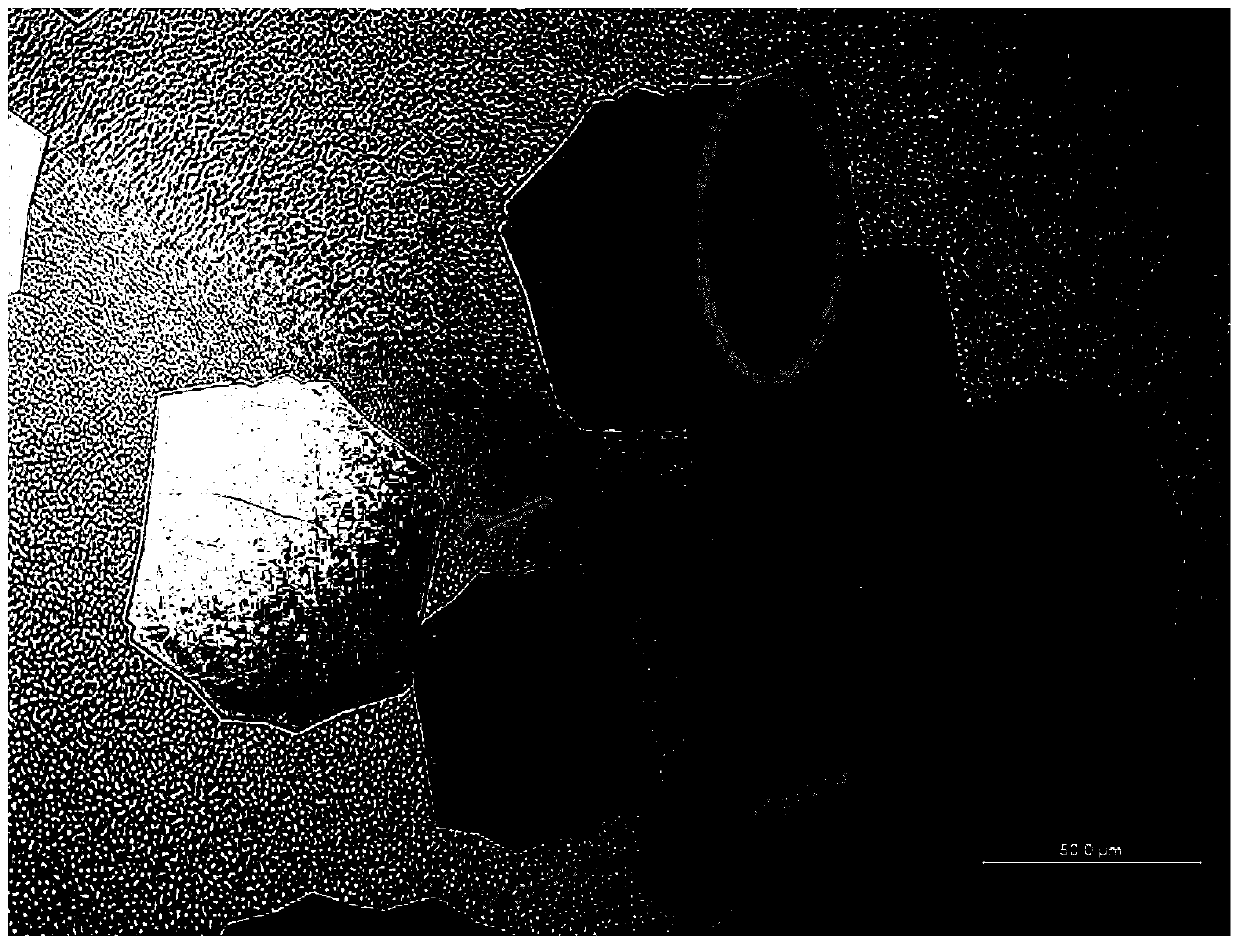

[0042] see Figure 3 to Figure 5 , the invention provides a graphene characterization method.

[0043] Firstly, a graphene single crystal grown directly on a copper substrate by chemical vapor deposition (CVD), such as image 3 Shown is an optical microscope image of a single crystal of graphene on a copper substrate. The points pointed by the black arrows in the figure are individual graphene single crystals, and some graphenes are formed by connecting two or three small-sized graphene single crystals.

[0044] It should be pointed out that, image 3 The light-colored fringes in the area indicated by the dashed box in the middle are the fringes of the copper substrate itself, rather than the graphene single crystal wrinkle or breakage.

[0045] Then the graphene single crystal on the copper substrate is oxidized in the air, so that the folds appear damaged, such as Figure 4 As shown, it is shown as an optical microscope picture of a graphene single crystal on a copper su...

Embodiment 3

[0049] Replace the copper substrate in Embodiment 1 or Embodiment 2 with an insulating substrate, such as silicon dioxide, hexagonal boron nitride, cubic boron nitride, etc., and replace the corrosion solution with the corrosion solution of the corresponding material, using basically the same The method characterizes graphene and finds the damaged part of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com