Calcium hypochlorite filter cake drying device

A drying device, calcium hypochlorite technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of long drying time, uneven drying, incomplete drying, etc., to achieve thorough drying, Even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

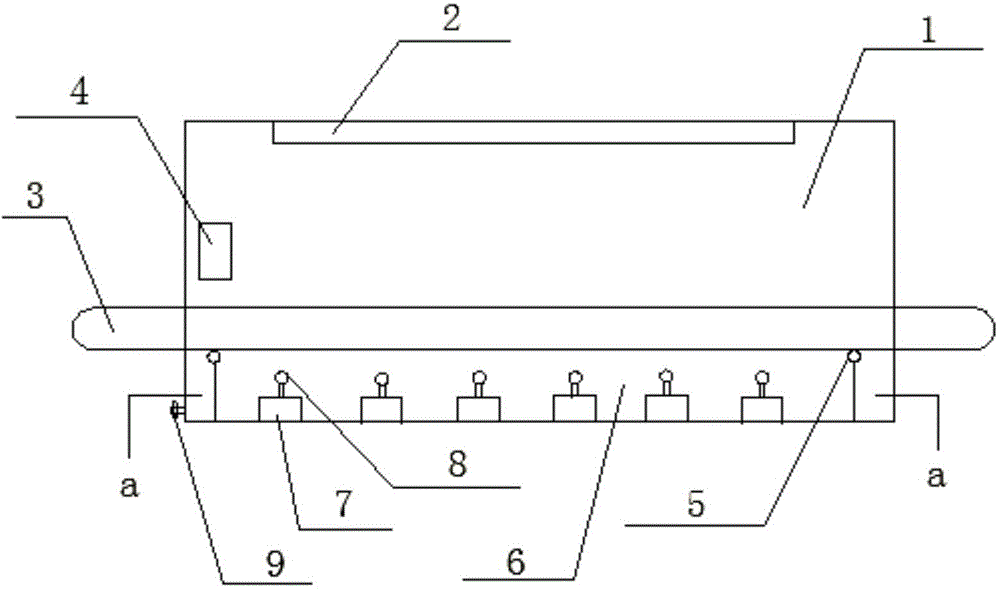

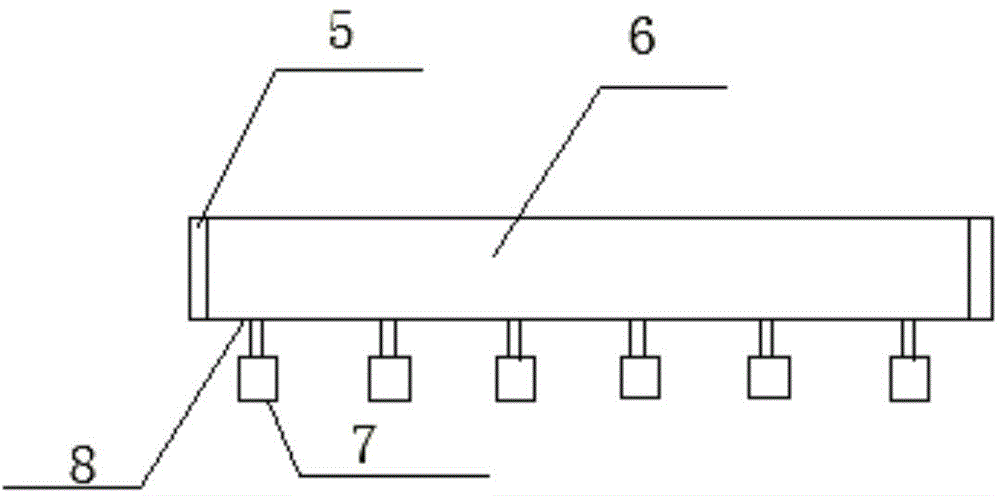

[0014] Such as figure 1 , 2 As shown, a calcium hypochlorite filter cake drying device includes a body 1, a fan 2 on the upper end of the body 1, a control device 4 outside the body 1, heating plates on the inner walls on both sides of the body 1, and a transmission at the lower end of the body 1. Mesh belt 3, the bottom of the transmission mesh belt 3 is provided with a water tank 6 with an open upper end equivalent to the surface area of the transmission mesh belt 3, and one side of the water tank 6 is provided with some suction nozzles 8 near the upper end. Several suction nozzles 8 have the same spacing as the upper and lower ends of the water tank 6, and each suction nozzle 8 is connected to an air pump 7, and the bottom of one end of the water tank 6 is provided with a drain valve 9, which can be opened when there is a lot of water in the water tank 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com