Multi-pass shell-and-tube flooded heat exchanger

A flooded, heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, refrigeration and liquefaction, etc., can solve the problem of poor stability of the oil return system, large increase in unit cost, and high cost Not inferior to other problems, to achieve the effect of easy anti-corrosion treatment, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

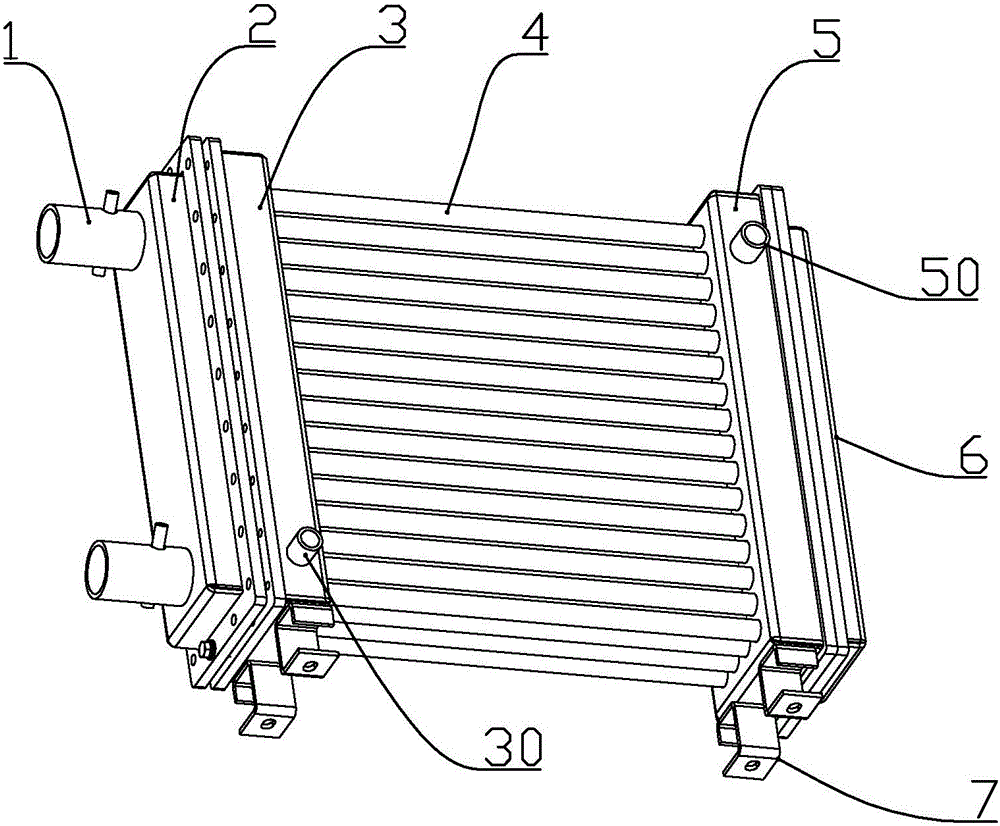

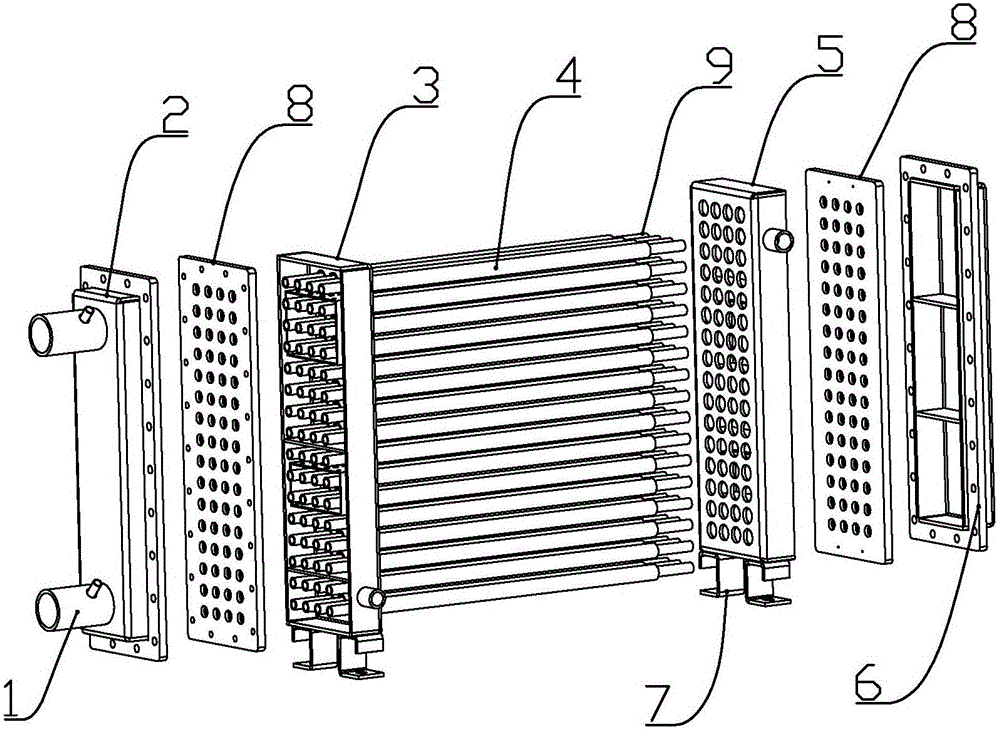

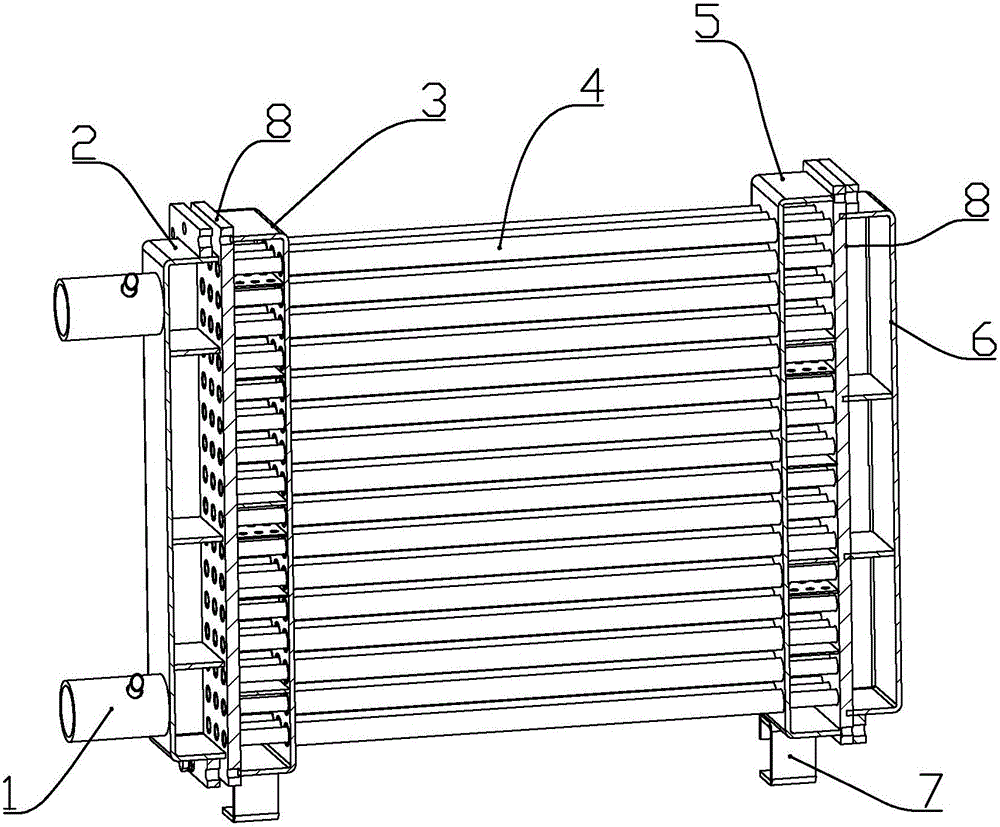

[0018] according to Figure 1 to Figure 5 As shown, the present embodiment is a multi-shell tube flooded heat exchanger, including a plurality of shell tubes 4 distributed in an array, a plurality of heat exchange tubes 9 passing through each shell tube, and the two ends of each shell tube respectively A first outer tube box 3 and a second outer tube box 5 are connected and communicated, and two tube sheets respectively connected to both ends of each heat exchange tube and connected to the outside of the first outer tube box and the second outer tube box 8, and a first inner tube box 2 and a second inner tube box 6 respectively connected to the outside of the two tube sheets; the two ends of the shell tube are sealed with the first outer tube box and the second outer tube box respectively Insertion, the two ends of the heat exchange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com