A split-type internal combustion engine combustion cylinder piston locking rebound device

A split type internal combustion engine and combustion cylinder technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high engine combustion chamber temperature, high combustion cylinder pressure, and increased compression ratio, so as to ensure stable operation and responsiveness Timely, unlocking force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

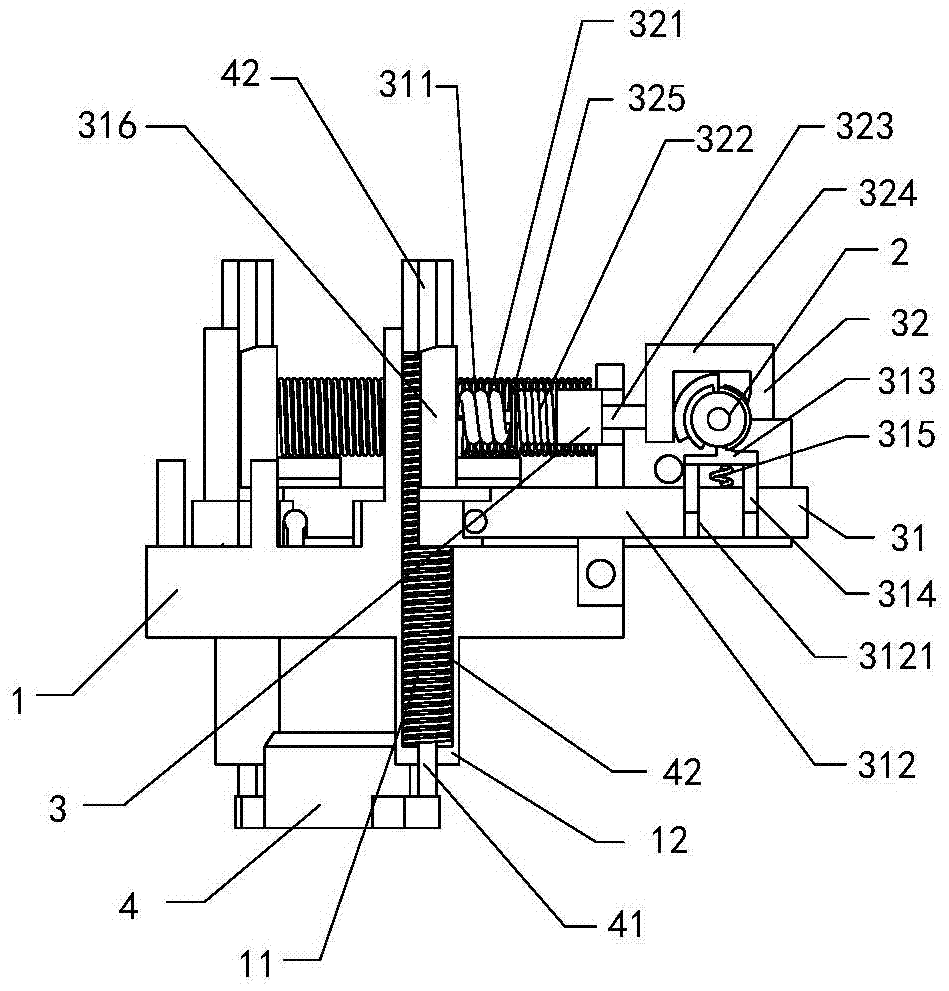

[0022] According to reference figure 1 As shown, a split-type internal combustion engine combustion cylinder piston locking and rebounding device includes: a working cylinder head 1, a camshaft 2 located above the working cylinder head 1, a locking and rebounding device 3 connected to the camshaft 2, a penetrating The piston 4 of the working cylinder cylinder head 1 and the camshaft 2 are used to control the locking rebound device 3, thereby controlling the position of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com