Mining rotor type variable shotcrete machine

A technology of concrete spraying machine and rotor type, which is applied in mining equipment, earthwork drilling, wellbore lining, etc., and can solve the problems of low material utilization rate, large material rebound, and ejection pulse of concrete spraying materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

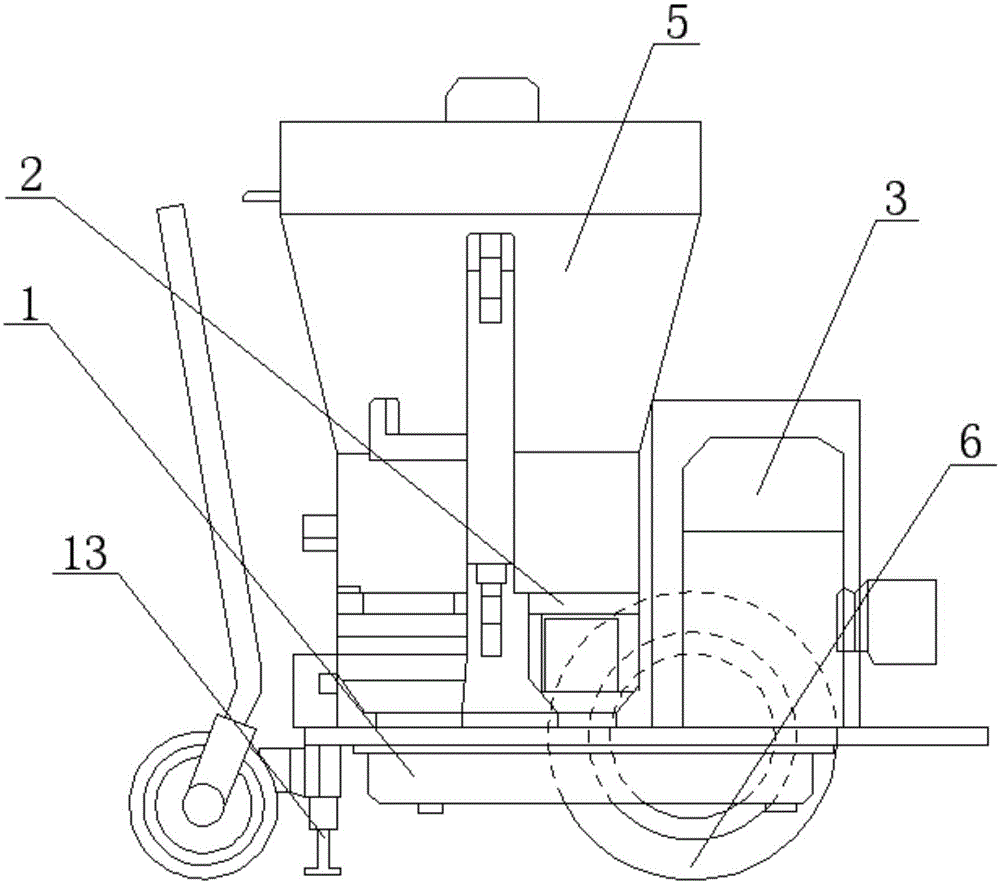

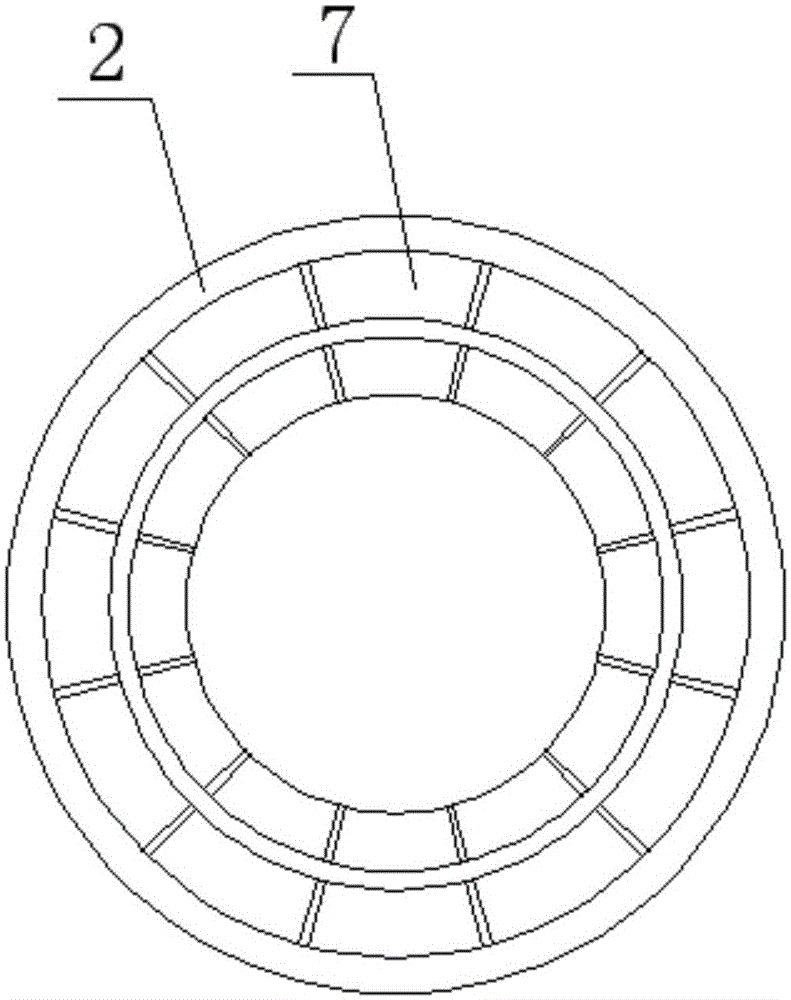

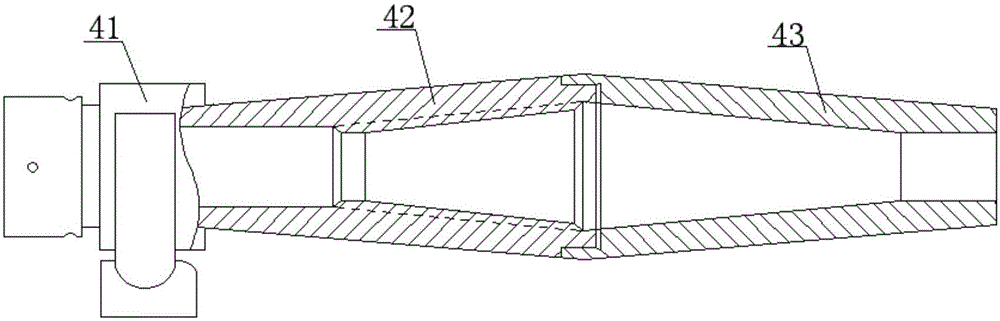

[0016] like Figures 1 to 4 As shown, the mine-used rotor-type variable-variable concrete sprayer of the present invention includes a vehicle frame 1, a rotor body 2 arranged on the vehicle frame 1, a drive motor 3 for driving the rotor body 2 to rotate, and a discharge port at the bottom of the rotor body 2. Gun head spray pipe 4 and hopper 5 located at the top of rotor body 2, wheels 6 are provided at the bottom of frame 1, auxiliary support device 13 is provided at the bottom of frame 1, in order to ensure the stability during construction work, drive motor 3 adopts The variable frequency speed regulating motor can steplessly adjust the feeding amount, which greatly facilitates the optimization of the spraying process parameters during the construction process. The driving motor 3 is connected to the rotating shaft of the rotor body 2 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com