U-shaped suspension ring structure

A U-shaped, lifting ring technology, applied in building construction, construction, building materials processing and other directions, can solve the problems of general lifting ring tensile strength, large material consumption, large lifting ring diameter, etc., to save materials and high tensile strength. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

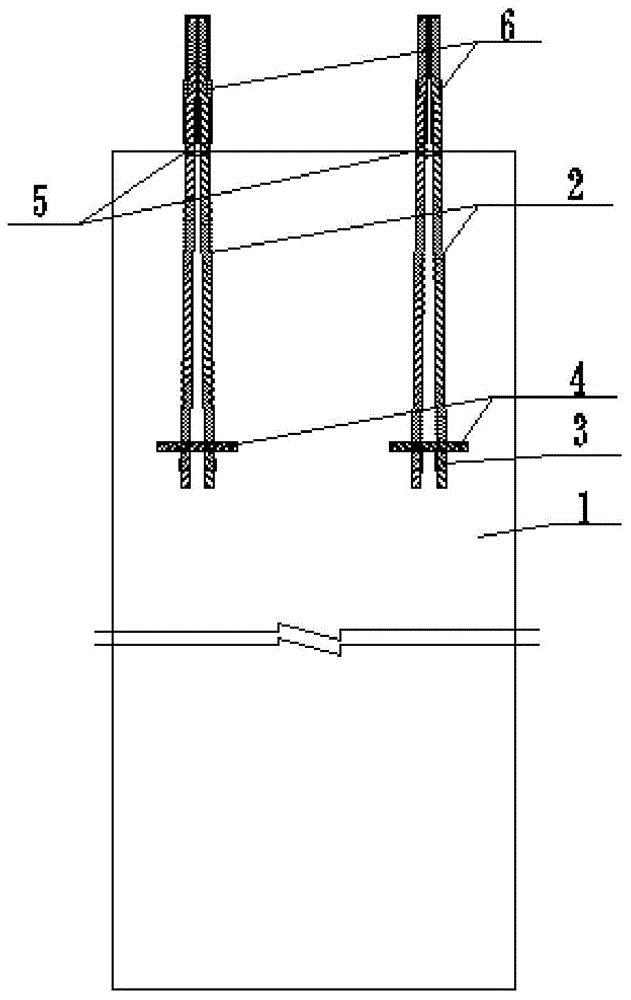

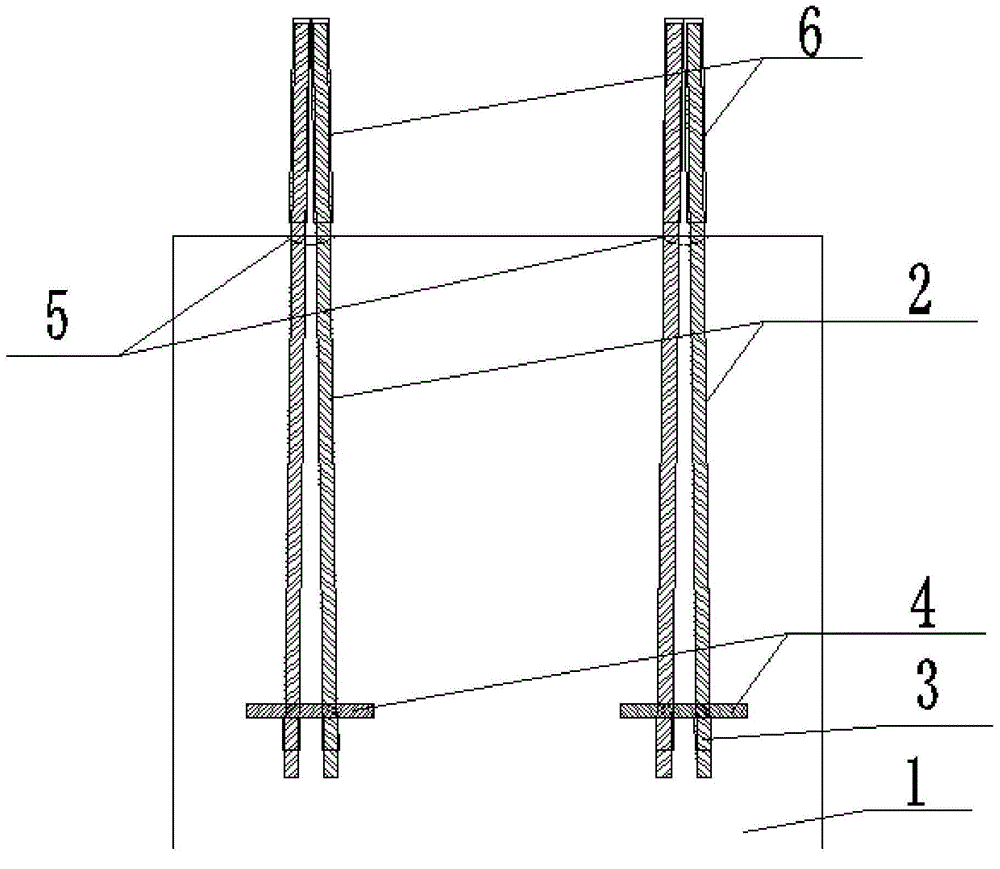

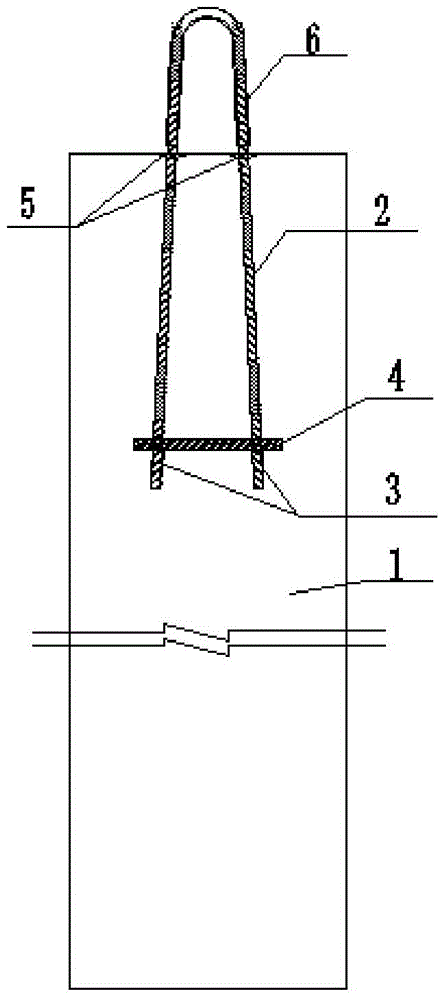

[0015] Such as Figure 1-Figure 3 As shown, a specific embodiment of the present invention, a U-shaped suspension ring structure, includes a prefabricated component 1 and a U-shaped suspension ring 2, the U-shaped suspension ring 2 is pre-embedded in the prefabricated component 1, and the U-shaped suspension ring 2 is a U-shaped steel strand. The end of the U-shaped suspension ring 2 in the component 1 is provided with an extrusion sleeve 3, and a steel anchor plate 4 is provided between the extrusion sleeve 3 and the U-shaped suspension ring 2, and the embedding point of the U-shaped suspension ring 2 on the surface of the prefabricated component 1 A circular bevel 5 is provided at the position, and a sleeve 6 is sheathed on the outside of the U-shaped suspension ring 2 exposed to the outside of the prefabricated component 1 .

[0016] In the further optimized technical solution of the present invention, the U-shaped suspension ring 2 is a U-shaped steel strand, and the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com