Structure for rapidly restoring hinge joint of hollow slab bridge and construction method thereof

A hollow slab bridge and construction method technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve the problems of affecting traffic, affecting the clearance height under the bridge, increasing the difficulty of construction, etc. The effect of shear capacity, the ability to increase transverse bending and tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

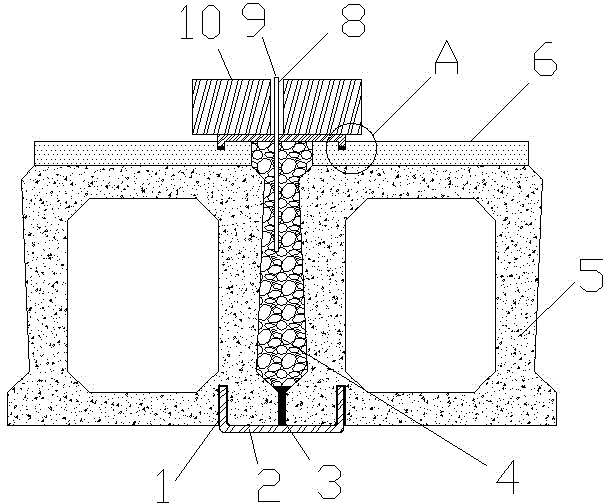

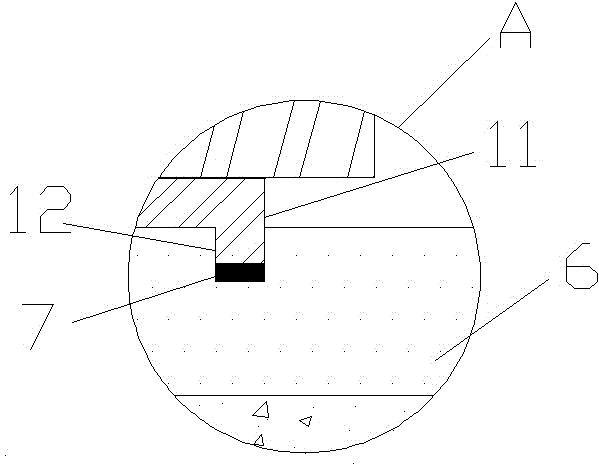

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The repair structure and construction method corresponding to the first embodiment of the present invention are as follows:

[0025] Step 1. Peel off the bridge deck surface on both sides of the damaged hinge joint, the stripping width is 50mm greater than the width of the sealing plate, and chisel away the hinge joint concrete in the damaged hinge joint;

[0026] Step 2. On the lower surface of the bottom plate, determine the position of the U-shaped ribs (2) at a distance of 250mm along the hinge joint, and the two planting holes (1) corresponding to the same U-shaped bar (2) are marked under the base plate symmetrically to the hinge joint On the surface, according to the drawing or using a steel bar locator, determine the position of the prestressed steel bars and ordinary steel bars in the bottom plate near this position. If the hole position conflicts with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com