A method for extracting steviol glycosides from biological enzyme fermentation broth

A technology of steviol glycosides and fermented liquid, which is applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc. It can solve the problems of not being able to meet the requirements of consumers, the difficulty of purifying high-purity products, and the restricted supply of raw materials. Achieve the effect of reducing regeneration maintenance cost, ensuring uniformity, preventing over-fermentation or

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

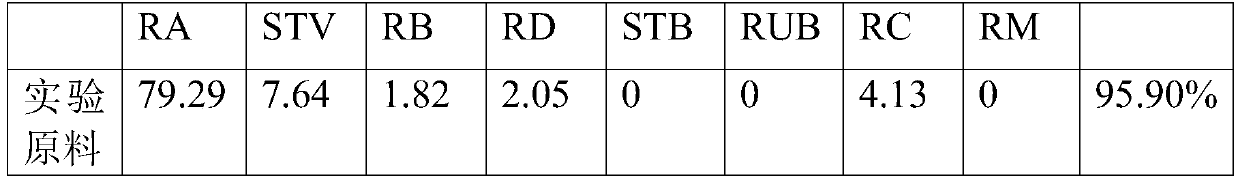

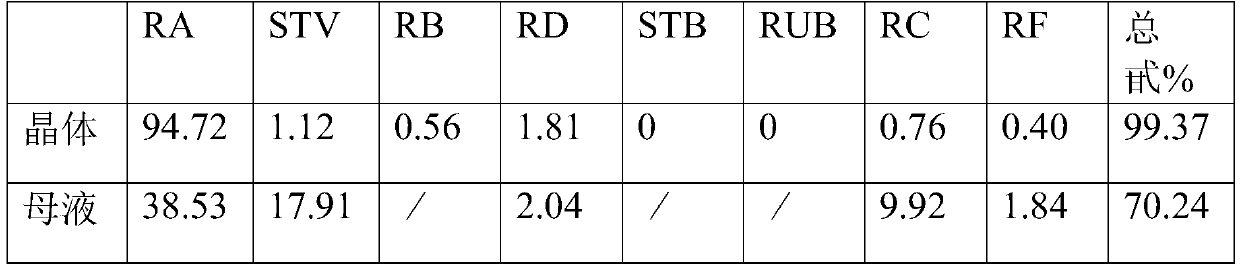

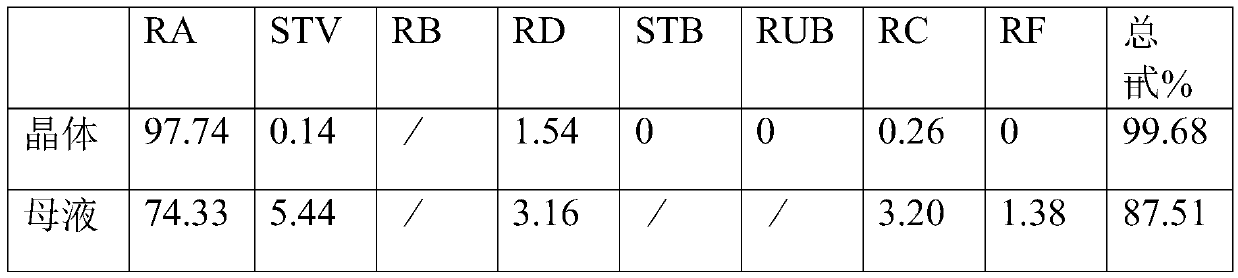

[0027]The monosaccharide bio-enzyme fermentation liquid selected in this embodiment is the fermentation liquid produced by the fermentation of Saccharomyces species. The method of the present invention for extracting high-purity steviol glycoside RA from monosaccharide fermentation liquid, firstly, pretreating the monosaccharide biological enzyme fermentation liquid:

[0028] Using saturated steam, 3502 ml of fermentation broth was heated to 95°C and maintained for 20 minutes. Use circulating cooling water to reduce the temperature of the primary clarified fermentation broth to ≤50°C. Add citric acid to adjust the pH of the monosaccharide fermentation broth to 4.0. Add 8% of the "natural organic polymer polysaccharide composite flocculant" configuration solution, and use a high-speed centrifuge with a separation factor ≥ 5000 to perform a decontamination and separation of the above-mentioned pretreated fermentation broth, with a light transmittance ≥ 80, to obtain a clarifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com