Torque-speed sensing device for center shaft of electric bicycle

A technology for electric bicycles and speed sensing, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve the problems of inconspicuous changes in displacement, decreased working stability and reliability of sensors, and inaccurate output of induced potential signals, etc. problems, to achieve the effect of good consistency and versatility, stable and reliable working performance, and stable driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

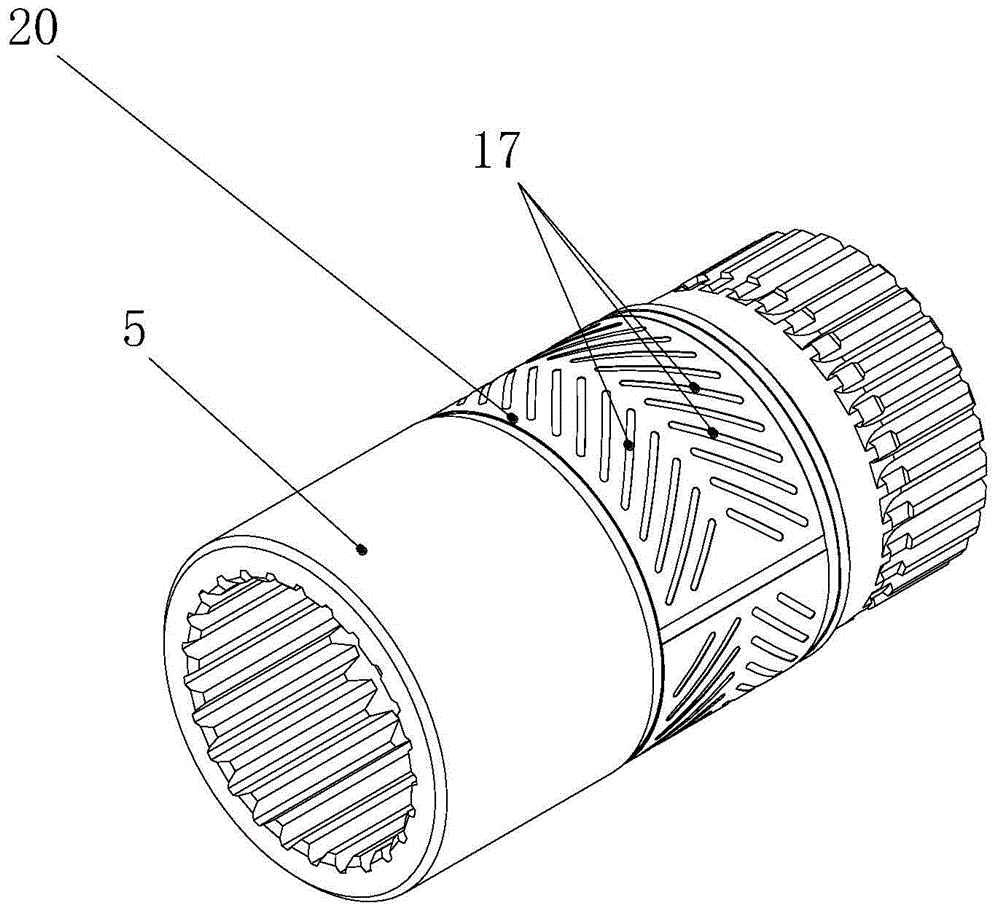

[0028] Figure 1 to Figure 4 A specific embodiment of the torque speed sensor device for the central axis of this electric bicycle of the present invention is shown, which is mainly composed of a left wrist 1, a right wrist 2, a central axis 4, a torque sleeve 5, a signal processing circuit board 6, a guide Magnetic alloy sheet, magnetic gasket 8, lead wire 9, positioning bushing 10, steel wire circlip 11, speed induction magnet 12, left crank 13, right crank 14, bolt 15, chainring 16, magnetic alloy sheet 17 , Speed induction Hall 18, these parts of speed induction magnet 12 are formed.

[0029] Same as the conventional technology, when assembling, the central shaft 4 will be passed through the bottom bracket (not shown in the figure), and the two ends of the central shaft 4 are respectively fixedly connected to the left crank 13 and the right crank 14 by bolts 15, Simultaneously described central axis 4 is sleeved with chainring 16, and this chainring 16 is positioned at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com