Electric heating writing pad and production method thereof

A writing pad and electric heating technology, applied in writing pads, printing and other directions, can solve the problems of large volume, inconvenient transportation, cold and biting, etc., and achieve the effects of good integrity, superior use comfort, and longer service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

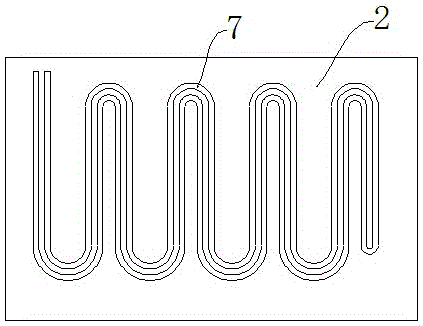

[0014] Such as figure 1 , figure 2 As shown, the electric heating writing pad described in this embodiment includes a non-slip rubber layer 3, a foamed sponge layer 2 and a PU leather layer 1, and a PU leather layer 1 is arranged on the upper surface of the foamed sponge layer 2, and the foamed sponge layer The lower surface of the layer 2 is provided with a non-slip rubber layer 3, and the inside of the foam sponge layer 2 is provided with a wiring groove 7, and a heating wire 4 is arranged in the wiring groove 7; device 5 and plug 6; the heating wire 4 is fixed in the wiring groove 7 by glue; the non-slip rubber layer 3, the foam sponge layer 2 and the PU leather layer 1 are bonded by glue.

Embodiment 2

[0016] In the production method of an electric heating writing pad described in this embodiment, first, a wiring groove 7 is punched in the middle of the foamed sponge layer 2, and the wiring groove 7 runs through the entire foamed sponge layer 2, and then the foamed sponge layer 2 is Bond the non-slip rubber layer 3 with glue; then arrange the heating wire 4 in the wiring groove 7; after the arrangement is completed, put glue in the wiring groove 7, and fix the heating wire 4 in the wiring groove 7; Then glue the PU leather layer 1 on the upper surface of the foam sponge layer 2 to form a composite body of three layers of materials; then use a punch and a mold to cut the shape of the body; the cut body is subjected to static compaction treatment : After a plurality of bodies are stacked, the adjacent bodies are separated by a partition plate, and a 50KG weight is placed on the top to stand still for 3 days, and it is in a normal temperature state; the body after standing and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com