Combined type packing

A technology of combined packing and random packing, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of not being able to effectively wet the packing surface and complex rectification is not suitable , mass transfer efficiency reduction and other issues, to achieve the effect of increasing the overall passability and improving the overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

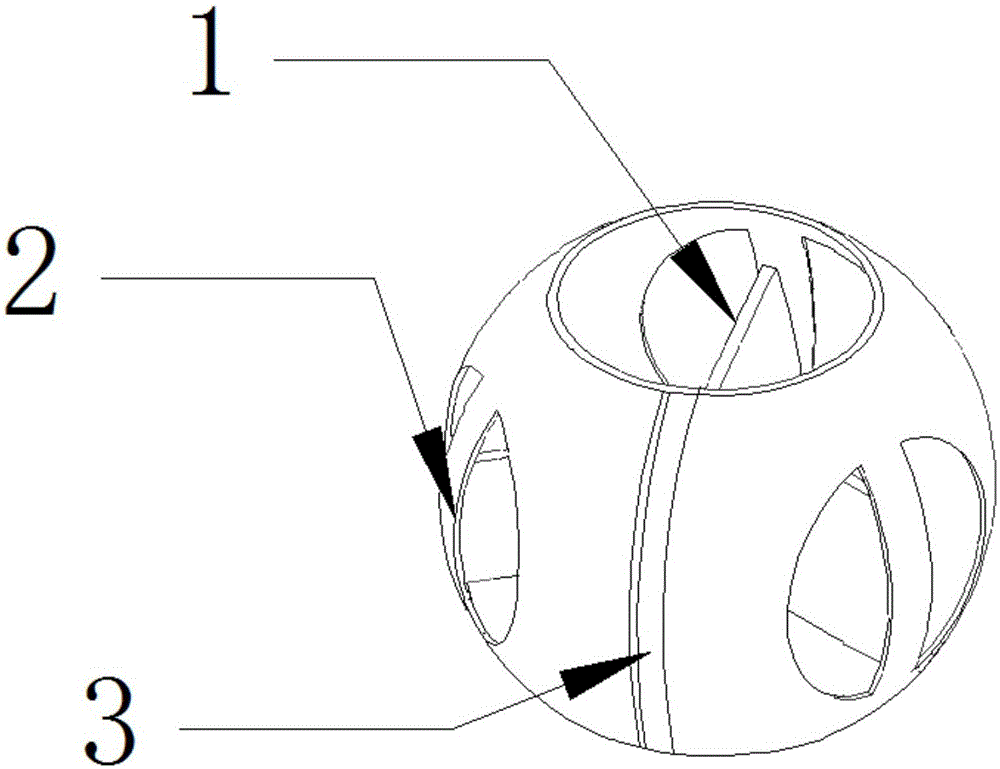

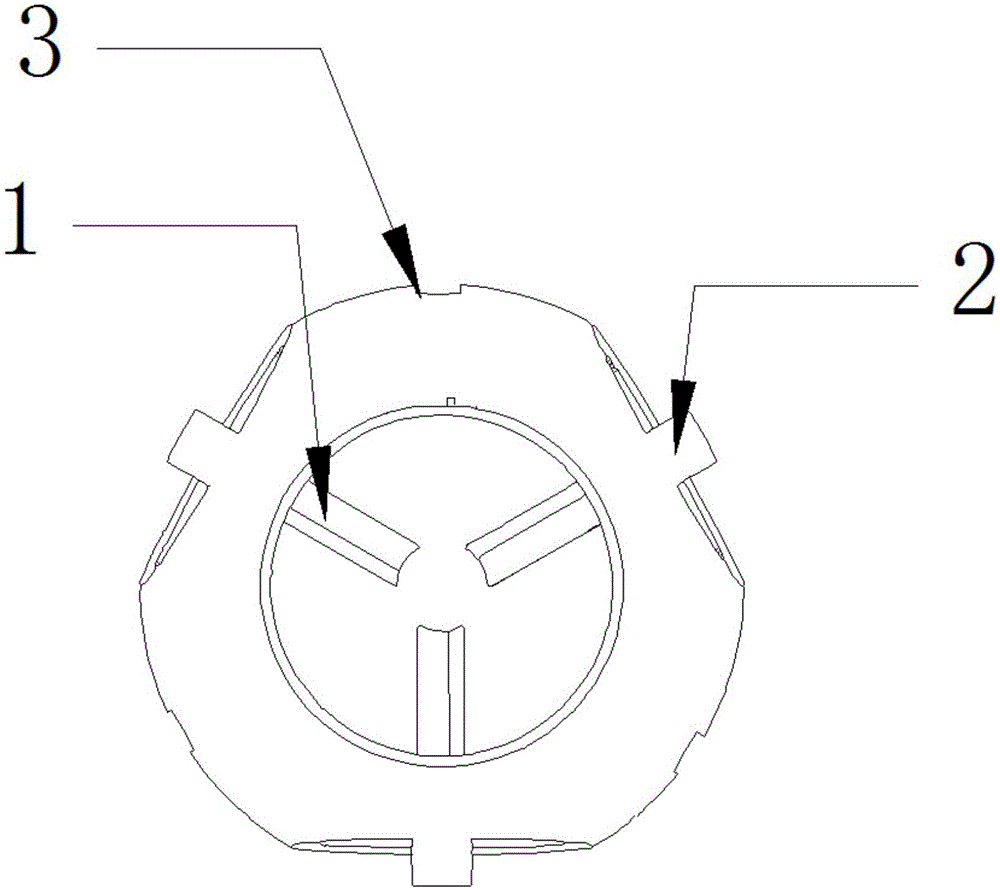

[0019] A combined packing in this embodiment is formed by splicing and combining several random packings. The structure of the random packing is as follows: figure 1 , 2 As shown, the random packing includes a three-dimensional annulus with upper and lower openings and several inner tongues 1, the three-dimensional annulus is also provided with a window, the middle position of the window is provided with a connecting bridge 2, and one end of the inner protruding tongue 1 is arranged on the connecting Bridge 2; between the window and the window is provided with a card slot 3 equal to the width of the bridge 2, and the outer mouth of the card slot 3 is provided with a buckle for connecting the bridge 2 and the card slot 3; The upper and lower ends of the bridge 2 are coated with an oleophilic coating, and the inner protruding tongue 1 is coated with an oleophobic coating.

[0020] The upper end of the combined packing in this embodiment is provided with several funnel-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com