A kind of rapid dehydration method of iron concentrate powder

A technology for fast dehydration of iron concentrate powder, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high moisture content in the final product, large investment in the dehydration system, high production cost, etc., and achieve a small footprint , Reduce investment and production costs, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of fast dehydration method of iron concentrate powder of the present embodiment, its steps are:

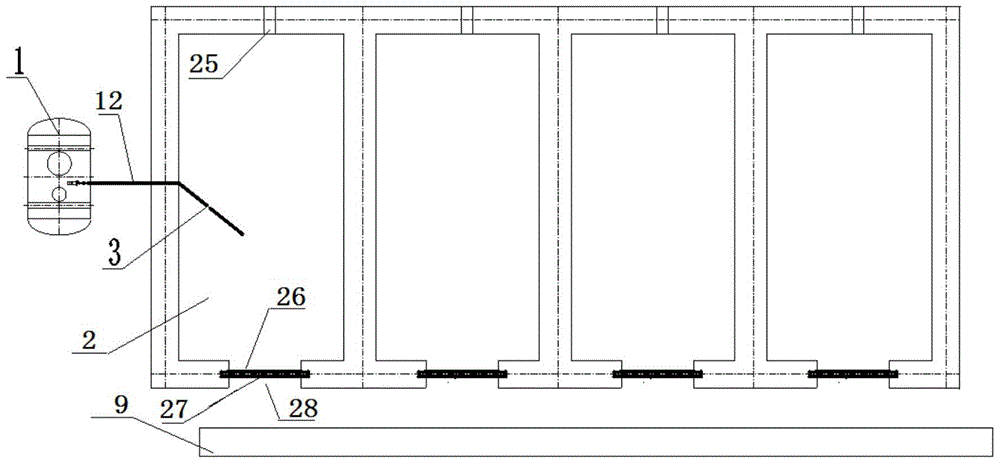

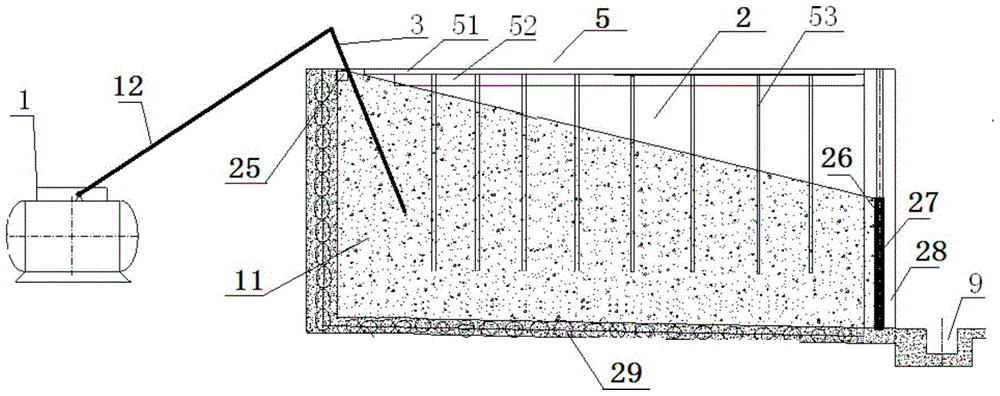

[0046] A. If figure 1 As shown, four sedimentation tanks 2 are arranged side by side; the sedimentation tank 2 includes a pulp inlet 25, a pulp spacer 27, a sedimentation tank discharge port 28 and a slope bottom 29 of the sedimentation tank; the pulp inlet 25 is opened in the sedimentation tank 2 On one side of the top, the ore discharge port 28 of the sedimentation tank is opened at the bottom of the other side wall of the sedimentation tank 2; the slurry spacer 27 is set on the inside of the ore discharge port 28 of the sedimentation tank; the bottom of the sedimentation tank 2 is a The slope bottom 29 of the sedimentation tank with a low inclination angle is 1%; the top of the sedimentation tank 2 is provided with a solar heating device 5;

[0047] B. Grouting: inject the slurry of iron concentrate powder 11 from the slurry inlet 25 of the sedimentation tank 2, ...

Embodiment 2

[0055] The basic steps of the rapid dehydration method of iron concentrate powder in this embodiment are the same as those in Embodiment 1, and the improvement is that the iron content grade of the iron concentrate powder 11 used is 68%. In step C, the filtering device 6 is a pulp spacer 27 with mesh. Such as figure 2 As shown, in step E, the solar heating device 5 includes a heat collecting layer 51, a heat storage layer 52 and a heat conducting rod 53; the heat collecting layer 51 is arranged on the top, and the heat storage layer 52 is placed below, and the fixed connection is an integral structure; the heat conducting rod The fixed end of 53 is vertically inserted into the heat storage layer 52 and fixedly connected with the heat collection layer 51, and the free end is vertically inserted into the iron concentrate powder 11 inside the sedimentation tank 2 to conduct heat to the iron concentrate powder 11, and the heat collection layer 51 is Flat-plate solar heat collect...

Embodiment 3

[0058] A kind of fast dehydration method of iron ore powder of this embodiment, its basic steps are the same as embodiment 2, the difference is: add electric heater in the pond peripheral wall, the inner wall material of sedimentation pond 2 pond wall is metal, increases the conduction of heat As a result, the outer wall is made of concrete, and the heat loss is slow, avoiding unnecessary waste of heat. The inclination slope of the slope bottom 29 of the sedimentation tank is 3%. In step D, let stand for 40 minutes. The heat conduction rod 53 is non-stretchable, and metal rods are arranged vertically and evenly on its surrounding wall to form a stirrer, which conducts heat while stirring the iron ore concentrate powder, so that the heat can be evenly distributed, thereby making the dehydration more uniform and further improving the dehydration efficiency .

[0059] In the rapid dehydration system of iron ore powder in this embodiment, an electric heater is added to the surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com