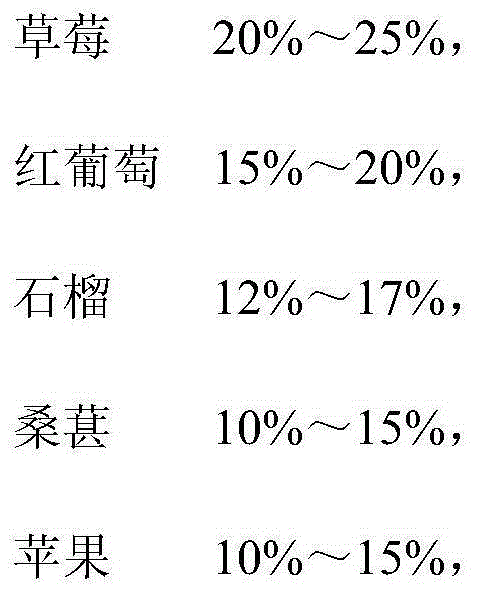

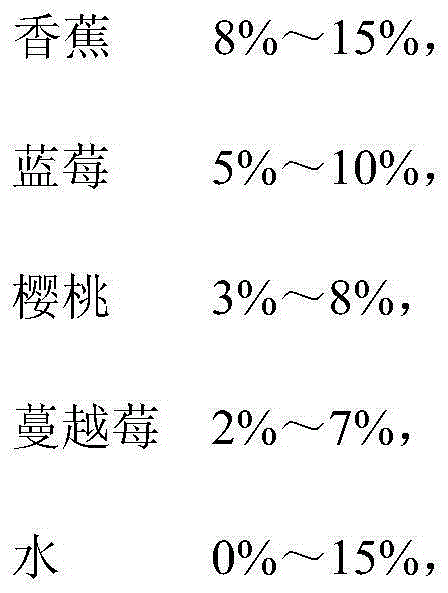

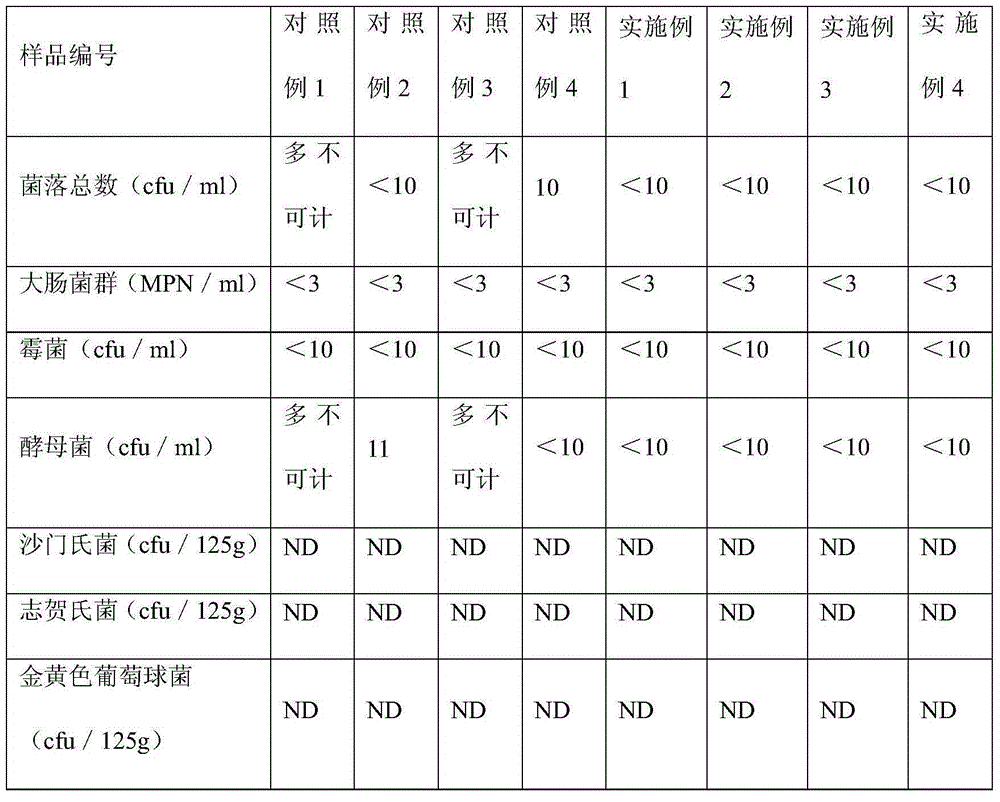

Compound fruit juice beverage and production process thereof

A compound fruit juice and production process technology, which is applied in food science, food preservation, application, etc., can solve the problems of high equipment and environmental requirements, increase the production cost of beverages, etc., reduce the risk of microorganisms, make the pulp uniform and delicate, and facilitate transportation stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of compound juice beverage, according to mass percentage, comprises 20% strawberry, 16% red grape, 14% pomegranate, 15% mulberry, 15% apple, 9% banana, 6% blueberry, 3% of cherries, 2% of cranberries.

[0039] The production technology of above-mentioned compound juice drink, comprises the following steps:

[0040] 1) Raw material pretreatment: Ripe strawberries and blueberries are beaten respectively to obtain strawberry pulp and blueberry pulp; after ripe apples are peeled and cored, pulping is performed to obtain apple pulp; after ripe bananas are peeled, Perform beating treatment to obtain banana pulp; the particle diameter of strawberry pulp, blueberry pulp, apple pulp, and banana pulp is less than 0.5mm, and then the obtained strawberry pulp, blueberry pulp, apple pulp, and banana pulp are homogenized at 40°C and 5Mpa. quality.

[0041] Ripe red grapes, pomegranates, mulberries, cherries, and cranberries are respectively squeezed to obtain red grape juice...

Embodiment 2

[0045] A kind of compound fruit juice beverage, according to mass percentage, comprises 25% strawberry, 15% red grape, 12% pomegranate, 10% mulberry, 12% apple, 8% banana, 5% blueberry, 6% of cherries, 7% of cranberries.

[0046] The production technology of above-mentioned compound juice drink, comprises the following steps:

[0047] 1) Raw material pretreatment: Ripe strawberries and blueberries are beaten respectively to obtain strawberry pulp and blueberry pulp; after ripe apples are peeled and cored, pulping is performed to obtain apple pulp; after ripe bananas are peeled, Perform beating treatment to obtain banana pulp; the particle diameter of strawberry pulp, blueberry pulp, apple pulp, and banana pulp is less than 0.5mm, and then the obtained strawberry pulp, blueberry pulp, apple pulp, and banana pulp are homogenized under 50°C and 20Mpa conditions. quality.

[0048] Ripe red grapes, pomegranates, mulberries, cherries, and cranberries are respectively squeezed to o...

Embodiment 3

[0052] A kind of compound juice beverage, according to mass percentage, comprises 20% strawberry, 20% red grape, 13% pomegranate, 10% mulberry, 10% apple, 15% banana, 5% blueberry, 3% cherries, 2% cranberries and 2% water.

[0053] The production technology of above-mentioned compound juice drink, comprises the following steps:

[0054] 1) Raw material pretreatment: Ripe strawberries and blueberries are beaten respectively to obtain strawberry pulp and blueberry pulp; after ripe apples are peeled and cored, pulping is performed to obtain apple pulp; after ripe bananas are peeled, Perform beating treatment to obtain banana pulp; the particle diameter of strawberry pulp, blueberry pulp, apple pulp, and banana pulp is less than 0.5mm, and then the obtained strawberry pulp, blueberry pulp, apple pulp, and banana pulp are homogenized at 65°C and 30Mpa. quality.

[0055] Ripe red grapes, pomegranates, mulberries, cherries, and cranberries are respectively squeezed to obtain red gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com