Cases

An electro-acoustic transducer, piezoelectric technology, applied in piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve the problems of increased distortion, sound pressure drop, loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

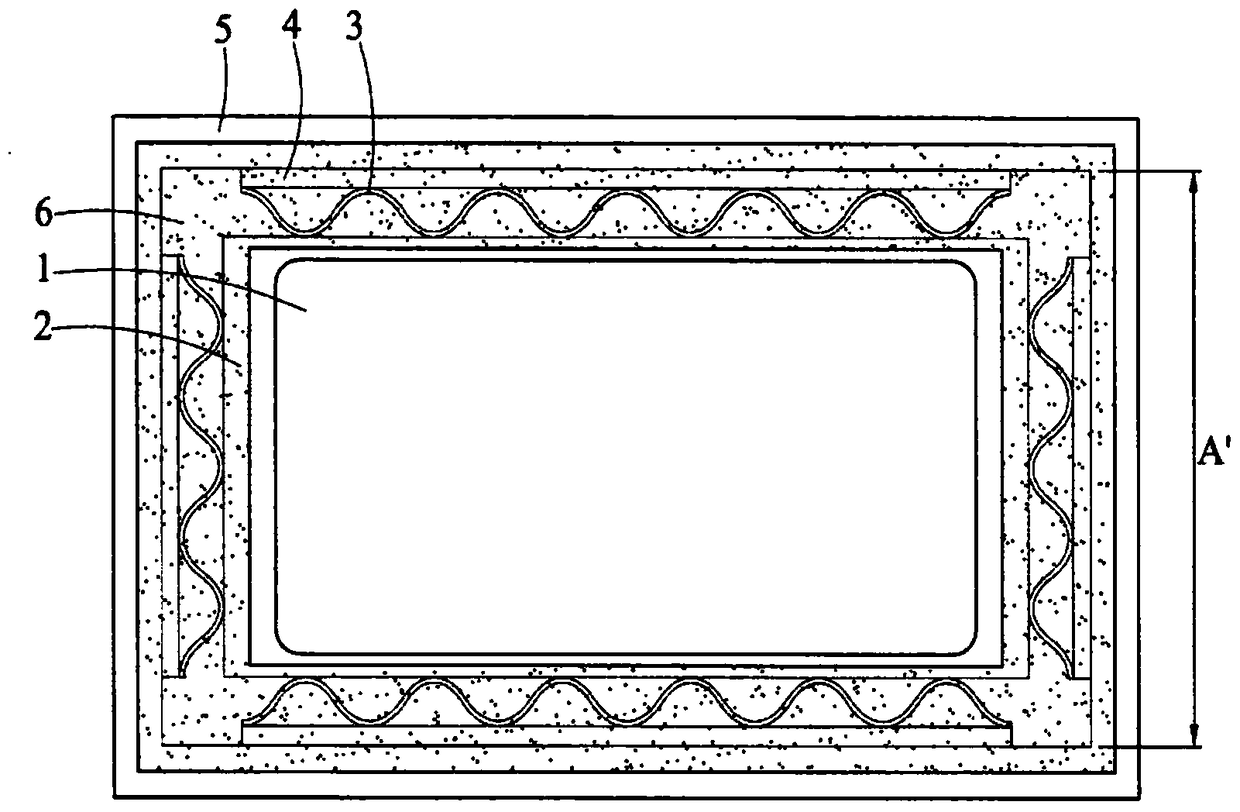

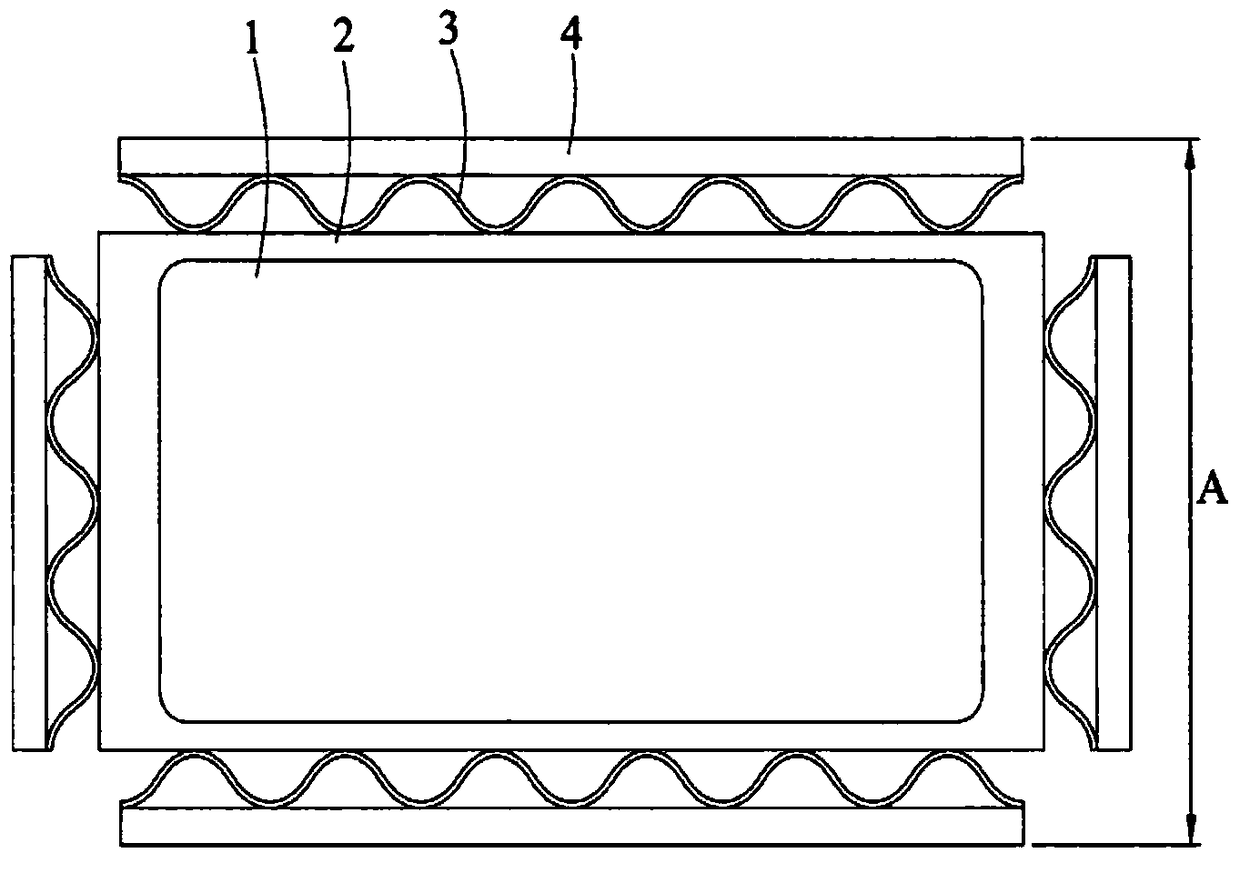

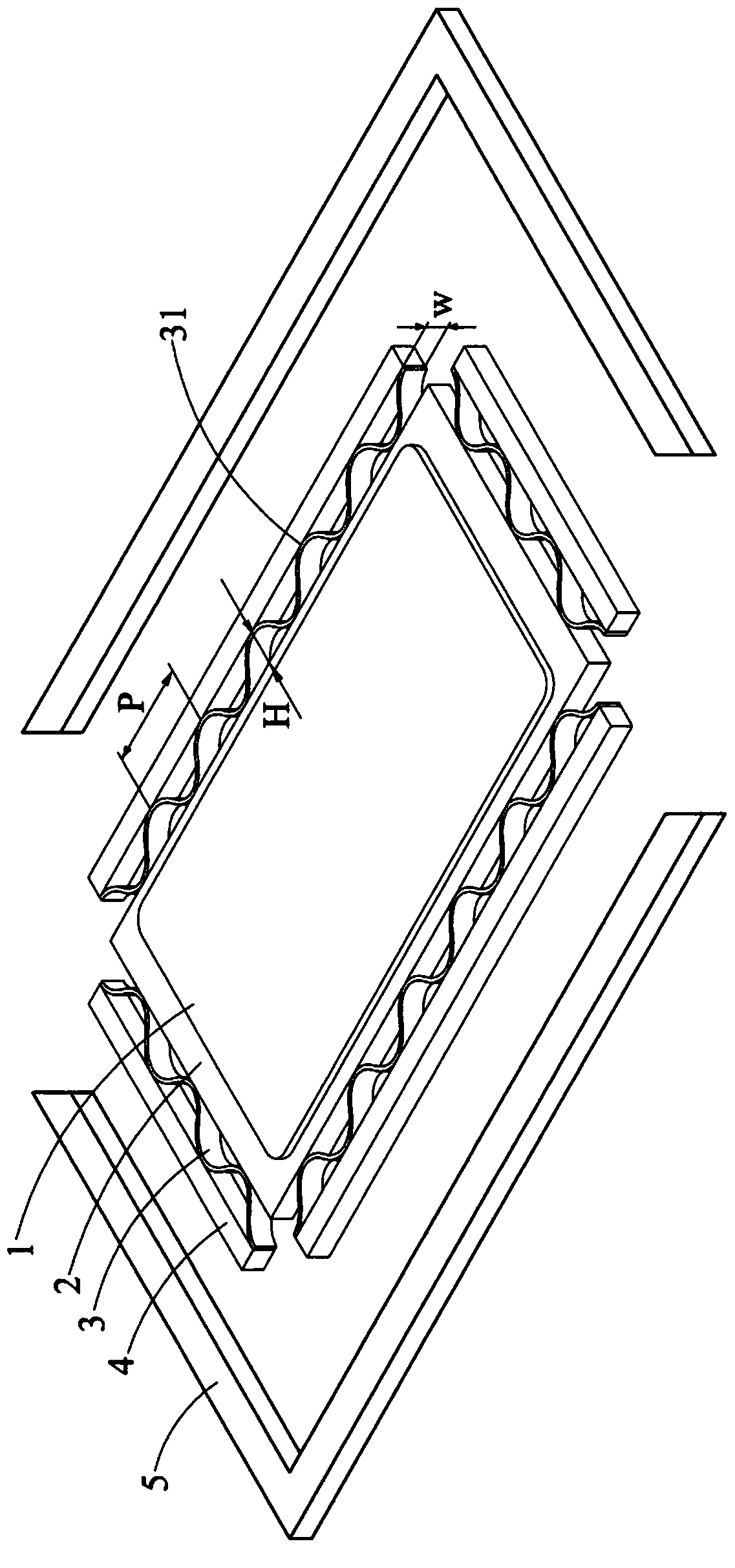

[0044] Embodiment 1, the piezoelectric electroacoustic transducer includes a diaphragm (85mm×42mm×0.1mm), a piezoelectric component (75mm×40mm×0.1mm) attached to the surface of the diaphragm, and is connected around the diaphragm An elastic component with multiple curved structures, a frame surrounding the elastic component, and a buffer body sandwiched between the elastic component and the frame. The distance between the plurality of curved structures is 10 mm, the height of each curved structure is 2 mm, the width is 0.5 mm, and the shape is arc-shaped. The ratio of the projected area of the inner frame of the frame to the combined planar projected area of the diaphragm, the elastic component and the buffer is 1 (that is, no compressive stress is applied). The test electrical parameter is 10Vrms, and the microphone receiving distance is 10cm. The sound pressure level (level) of embodiment 1 and the test result of total harmonic distortion are respectively as Figure 4A...

Embodiment 2

[0045] Embodiment 2: The difference from Embodiment 1 is that the width of the curved structure is 1 mm. The sound pressure level of embodiment 2 and the test result of total harmonic distortion are as Figure 4A and Figure 4B , Figure 5A and Figure 5B , Figure 6A and Figure 6B , Figure 7A and Figure 7B shown.

Embodiment 3

[0046] Embodiment 3: The difference from Embodiment 1 is that the width of the curved structure is 2mm. The sound pressure level of embodiment 3 and the test result of total harmonic distortion are respectively as Figure 4A and Figure 4B shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com