Method based on femtosecond laser technology for peeling GaN film and sapphire substrate

A sapphire substrate, femtosecond laser technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of GaN thin film vulnerable to damage, low yield, low efficiency, etc., to overcome vulnerability to damage, precision and efficiency Increased, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

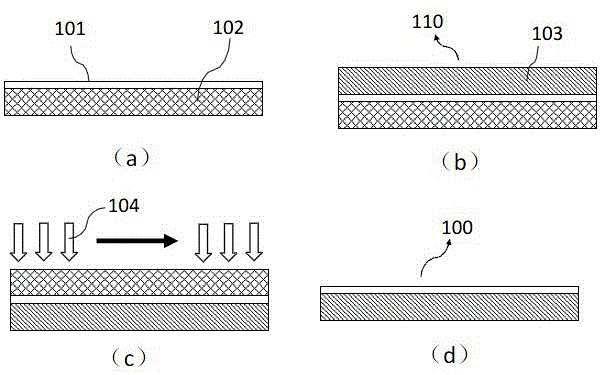

[0040] figure 1 It is a process flow chart of the GaN thin film and sapphire substrate peeling method based on femtosecond laser technology. Use MOCVD technology to deposit and prepare a GaN film 101 with a thickness of 1um on a sapphire substrate 102 with a good surface treatment (both sides of the sapphire substrate is polished), such as figure 1 (a); The target substrate 103 (silicon substrate) is directly bonded to the GaN thin film 101 to obtain a three-layer structure 110 of sapphire / GaN / target substrate, such as figure 1 As shown in (b): adjust the spot size of the femtosecond laser beam 103, and focus on the interface between the GaN film 101 and the sapphire substrate 102, scan from the edge of the three-layer structure 110 for laser irradiation until it is completed, as figure 1 As shown in (c): the three-layer structure 110 is heated to 30°C (the melting point of metal Ga), and the sapphire 102 is removed to obtain the double-layer structure 100 of the GaN film 101...

Embodiment 2

[0043] The difference from Embodiment 1 is that the bonding method between the target substrate 103 (silicon substrate) and the GaN thin film 101 is adhesive bonding.

Embodiment 3

[0045] The difference from Example 1 is that the Ga removal treatment is a femtosecond laser vaporization treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com