Organic Optoelectronic Device Test Fixture

A technology of optoelectronic devices and test fixtures, which is applied in the direction of the measuring device casing, etc., can solve the problems of cumbersome operation, damage to devices, and the influence of air on photoelectric devices, and achieve the effect of low cost and flexible transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

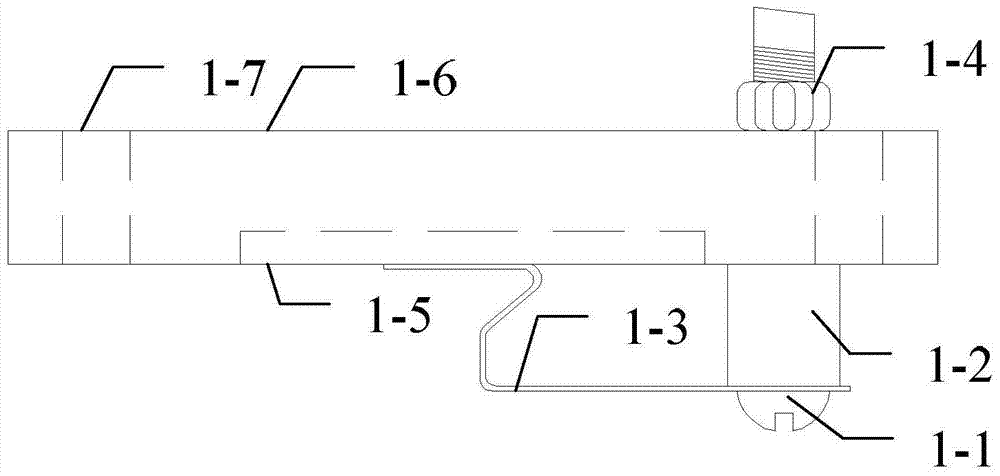

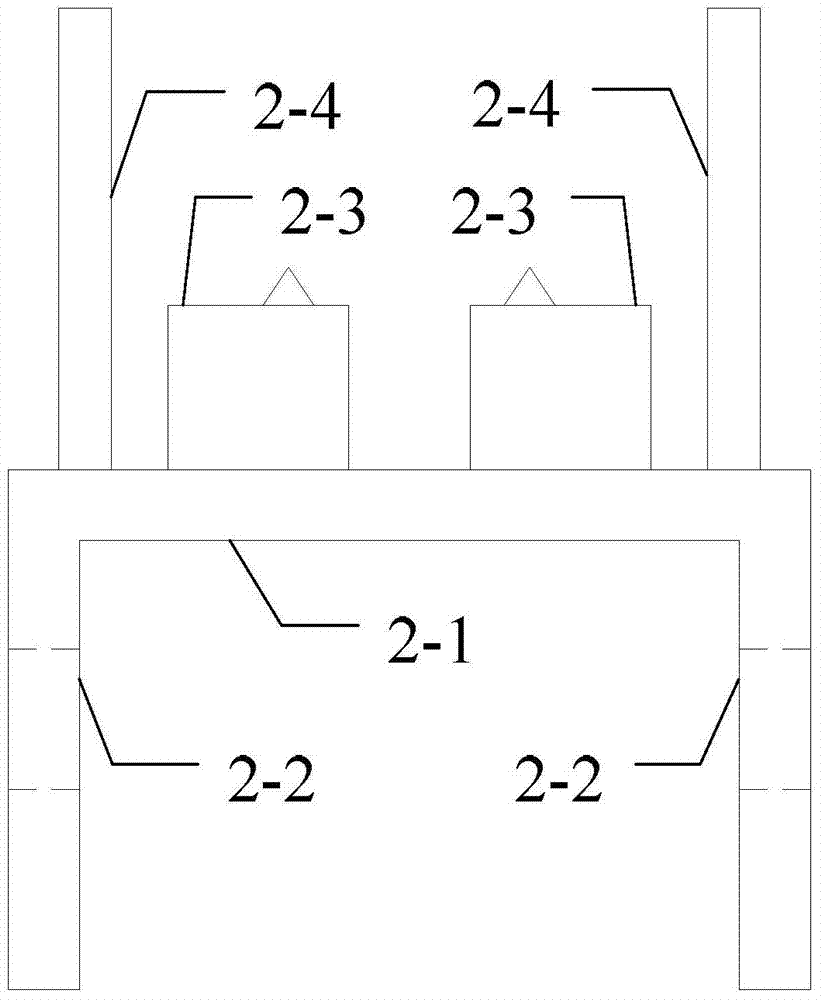

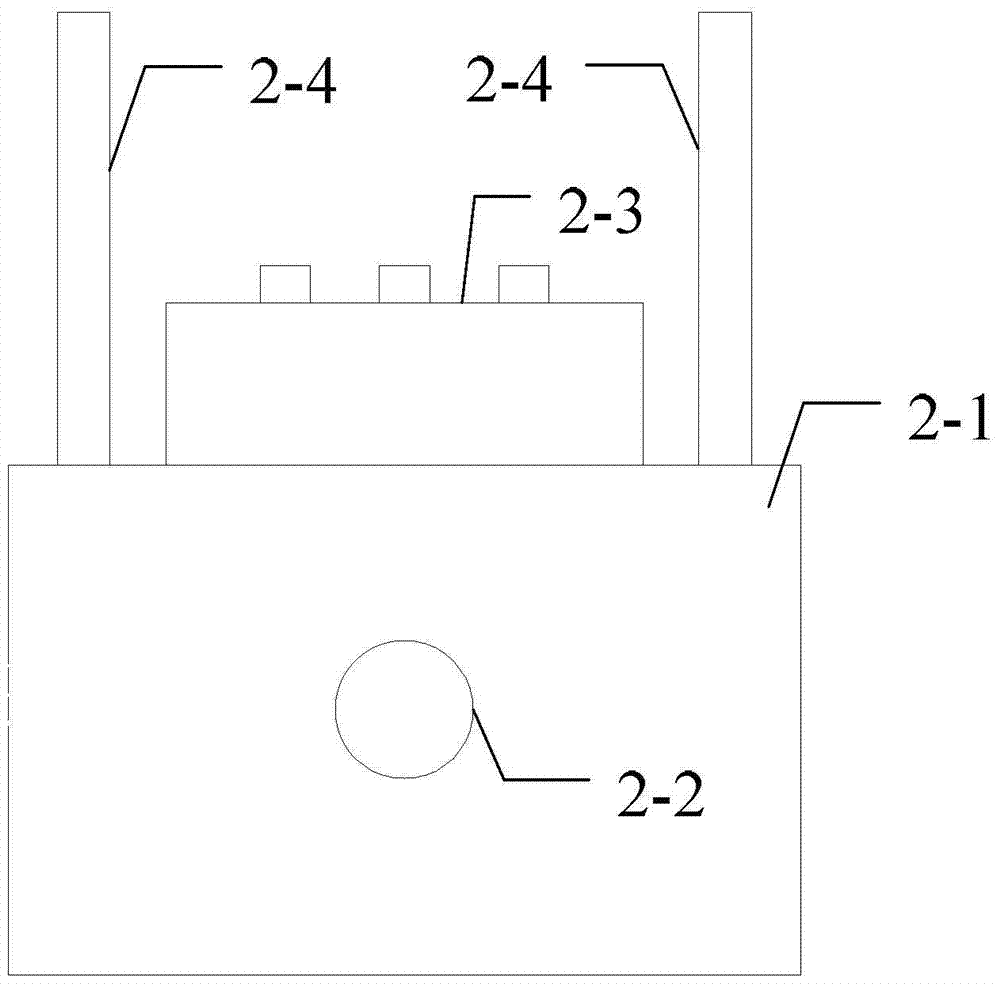

[0020] Specific implementation mode one: refer to Figure 1 to Figure 6 Specifically explain this embodiment, the organic photoelectric device test fixture described in this embodiment, it includes: a clamping part, a supporting part, a casing and an n-position switch 4;

[0021] The clamping part includes: a screw 1-1, a support column 1-2, a straight cantilever spring piece 1-3, a nut 1-4 and a clamping plate 1-6;

[0022] There are screw holes, device slots 1-5 and a plurality of limit holes 1-7 on the clamping plate 1-6 respectively, and a positioning hole is opened at one end of the straight cantilever spring leaf 1-3, and the screws 1-1 pass through in turn The positioning hole of the straight cantilever spring leaf 1-3, the screw hole of the support column 1-2 and the clamping plate 1-6, and the screw 1-1 is fixed on the clamping plate 1-6 by the nut 1-4, and The straight cantilever spring piece 1-3 can rotate around the screw 1-1, and the bent end of the straight cant...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is a further description of the organic optoelectronic device test fixture described in Embodiment 1. In this embodiment, an observation window is provided on the top cover 3-1.

[0033] The observation window in this embodiment is used to detect parameters such as luminance and color of the organic electro-reflective device during the testing process, or used for the light source entrance of the photovoltaic device.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment is a further description of the organic optoelectronic device test fixture described in Embodiment 2. In this embodiment, the material of the observation window is quartz.

[0035] In this embodiment, quartz is used as the light-transmitting material of the observation window, mainly because quartz absorbs less light, and the absorbed wavelength is below 200 nm, which ensures the light transmittance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com