Compressor impeller defect phased array ultrasonic detection method

A compressor impeller and ultrasonic detection technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of complex geometry of the impeller, mismatch of the surface shape of the probe wedge impeller, and difficulty in actual detection, etc., and achieve high detection energy , Easy detection, low missed detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

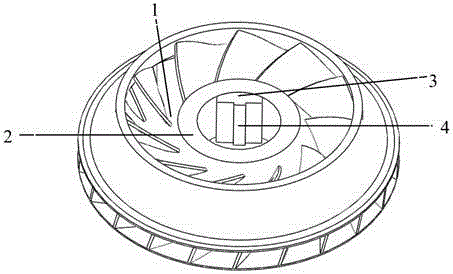

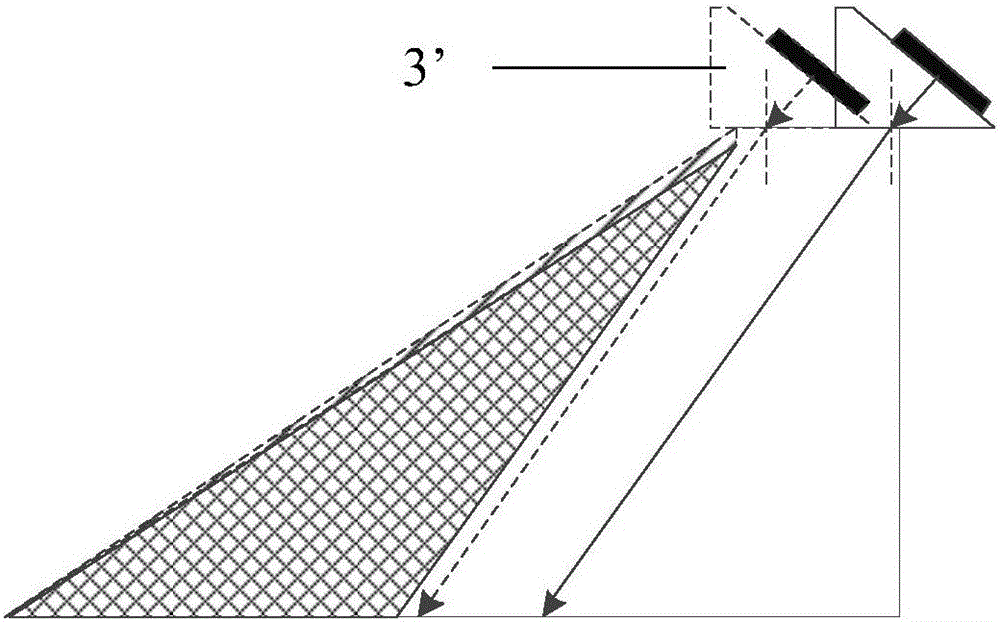

[0027] Such as figure 1 As shown, when the probe 4 is placed on the upper surface of the compressor impeller disc 2, the internal defects of the disc 2 can be detected, but since the probe 4 needs to be connected to the wedge 3' in the detection, the phased array probe The wedges are generally relatively large, while the small plane area on the upper surface of the wheel disc 2 restricts the placement of the probe 4 . For defects inside the blade root 1, when the probe 4 is connected to a wedge block 3' for detection, due to the structural discontinuity of the entire impeller, it has been verified by multiple tests that it is difficult for ultrasonic waves to propagate to the position of the blade root 1. It is difficult to detect the defects inside the blade root, and there are missed detections.

[0028] Therefore, when the probe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com