A passive high-temperature pressure sensor based on the principle of microwave scattering and its preparation method

A pressure sensor, microwave scattering technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., to achieve the effect of good stability, high sensitivity, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

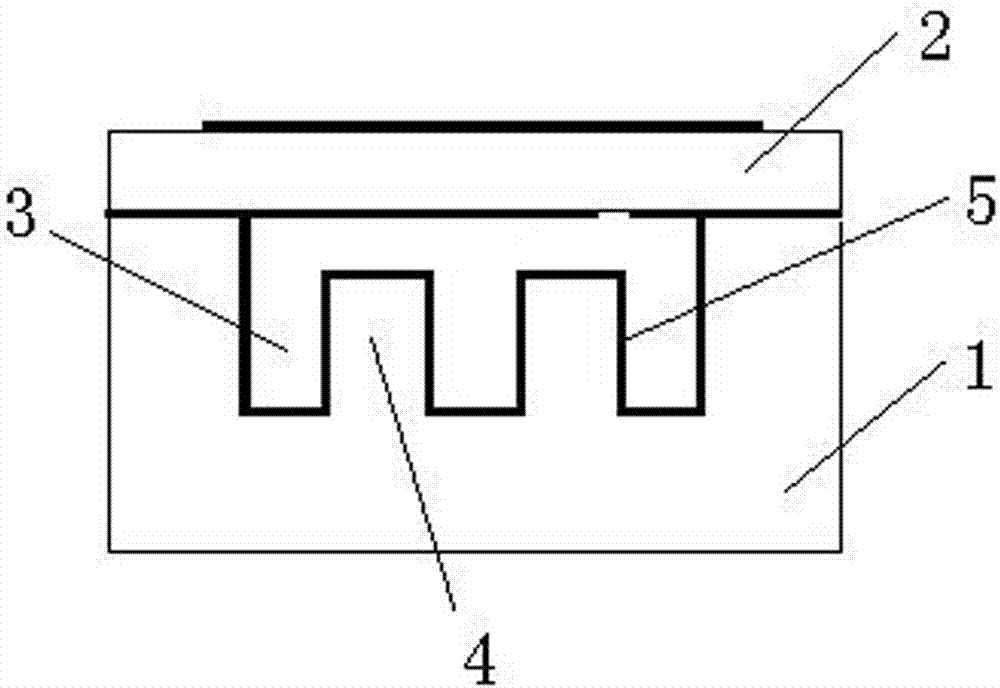

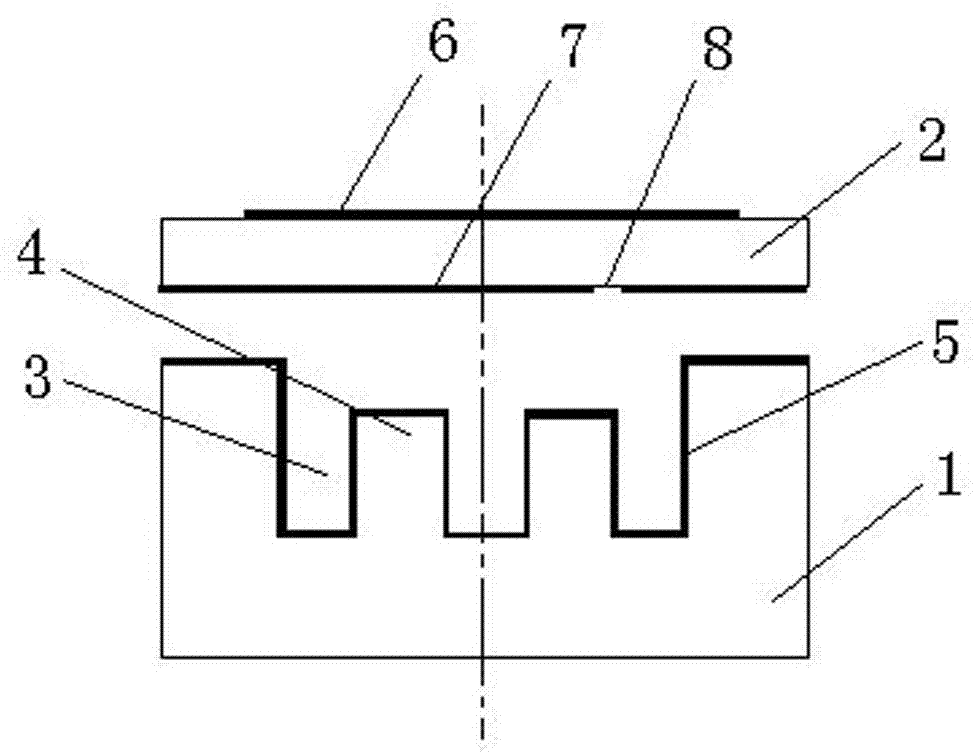

[0022] A passive high-temperature pressure sensor based on the principle of microwave scattering measurement, such as figure 1 , 2 As shown, it includes a cylindrical base structure 1 and a cylindrical sealing diaphragm 2 arranged from bottom to top, such as Figure 5 , 6 As shown, a concave cylindrical cavity 3 with an upward opening is set in the base structure, and four symmetrically raised inner cylinders 4 are arranged in the concave cylindrical cavity to reduce the center frequency of the concave cavity, and the height of the inner cylinder is lower than that of the concave cylindrical The upper end surface of the cavity, the upper end surface of the base structure, the inner surface of the concave cylindrical cavity, and the upper surface of the inner cylinder are sputtered with a metal layer 5, and the metal layer is a silver metal layer with a thickness of 0.1-0.2um; image 3 As shown, the upper surface of the sealing diaphragm is sputtered with a metal paste patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com