Mining method for long wall working face of ultra thick seam

A mining method and working face technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of mine pressure mitigation, increase of coal washing amount, and roof rock mixing, so as to reduce production costs and reduce coal washing. The effect of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand the present invention.

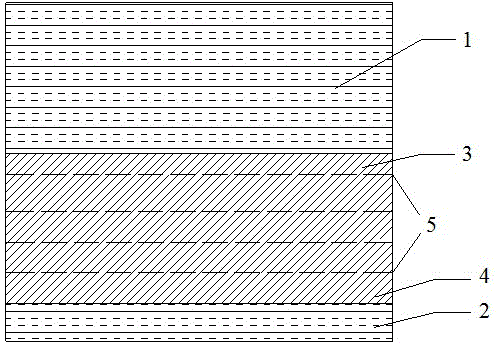

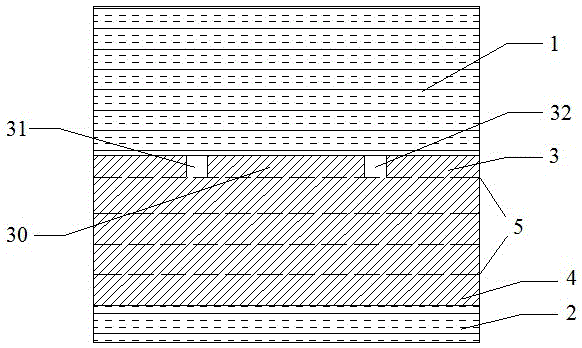

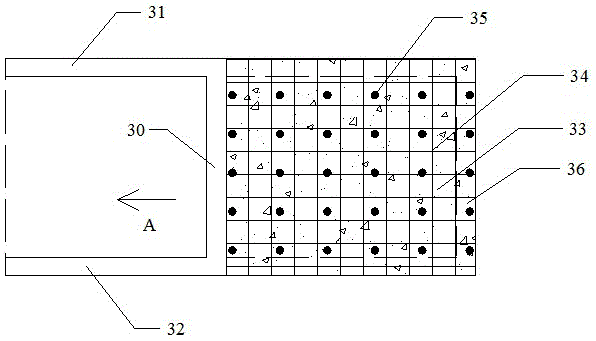

[0030] Such as Figure 1 to Figure 7 As shown, a longwall working face mining method of a huge thick coal seam comprises the following steps:

[0031] a. Layering of extremely thick coal seams: analyze the hydrogeological mining conditions of the roof rock layer 1, floor rock layer 2 and coal seams of the extremely thick coal seams, and divide the extremely thick coal seams into top layer 3, bottom layer 4 and middle Layer 5; the thickness of the top layer 3 is 2.5~4.5 m; the middle layer 5 and the bottom layer 4 are averagely layered according to the parameters of the fully mechanized caving support. The number of layers in middle layer 5 and bottom layer 4 according to the formula n =1+int( M / p ) calculation, where n is the layer number of middle layer 5 and bottom l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com