Industrial stable high-performance bolt steel and manufacturing method thereof

A high-performance, stable technology for high-strength bolt steels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0085] Table 1. Chemical composition of example and comparative steels, % by weight

[0086]

[0087]

[0088] Table 2 embodiment rolling process

[0089]

[0090] Table 3 embodiment heat treatment process

[0091] Numbering Quenching temperature tempering temperature a 880 500 b 880 550 c 880 600 d 880 650 e 880 400 f 880 450

[0092] Table 4 specific embodiment and test result

[0093]

[0094]

[0095]

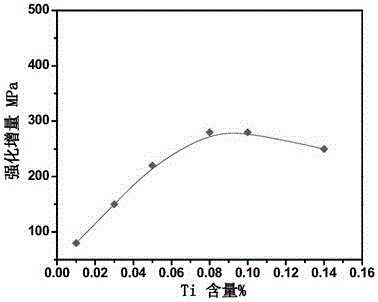

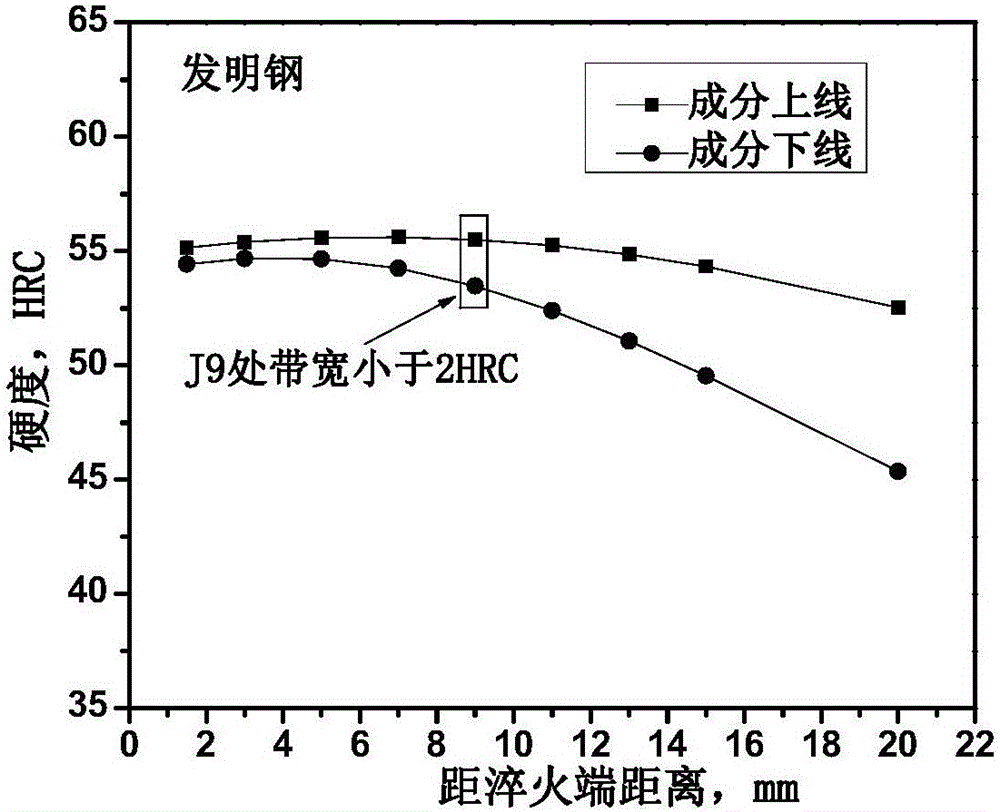

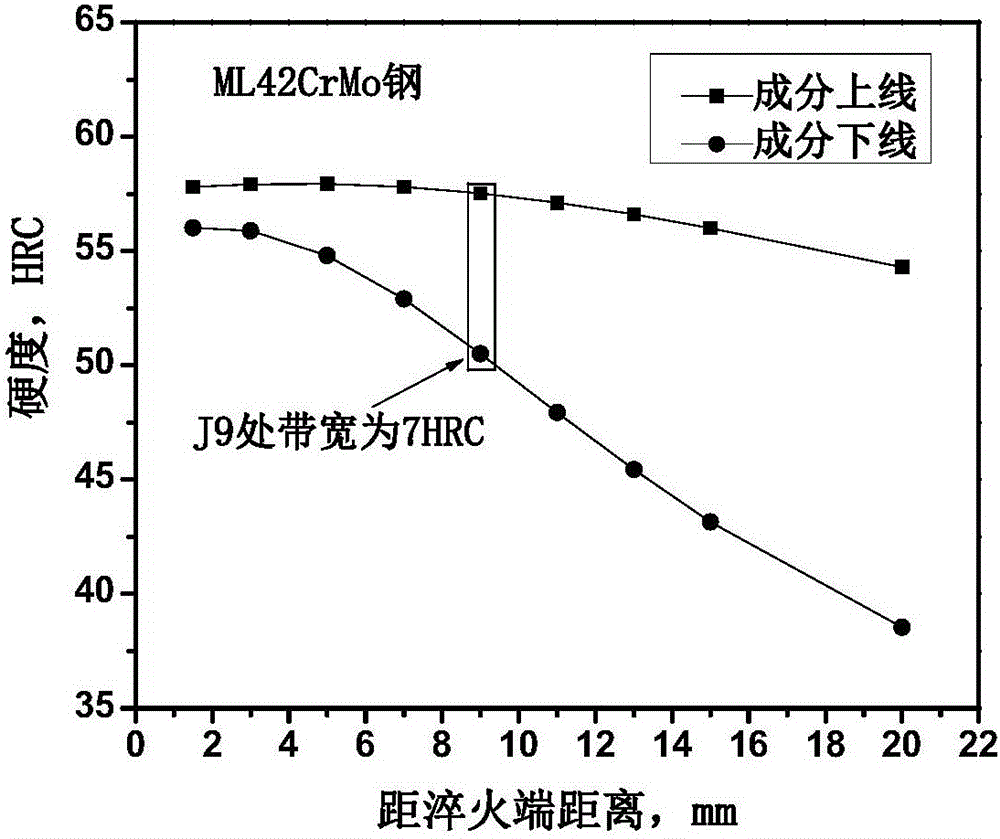

[0096] It can be seen from Table 4 that the delayed fracture performance of the steel of the present invention is significantly improved compared with the comparison steel 42CrMo at the strength level of 1040-1450MPa, showing excellent delayed fracture resistance, and the steel of the invention adopts precipitation strengthening instead of solid solution strengthening, The C content in steel is reduced from 0.42% to 0.28-0.37%, which can obtain good cold heading performance, and it can be estimated th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com