Garment tailoring and cloth spreading support

A technology for spreading cloth and clothing, which is applied in the field of clothing cutting and spreading supports, which can solve the problems of low efficiency, slow spreading speed, and unfavorable development of high-efficiency production of enterprises, and achieve the effect of improving production efficiency and scientific and practical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

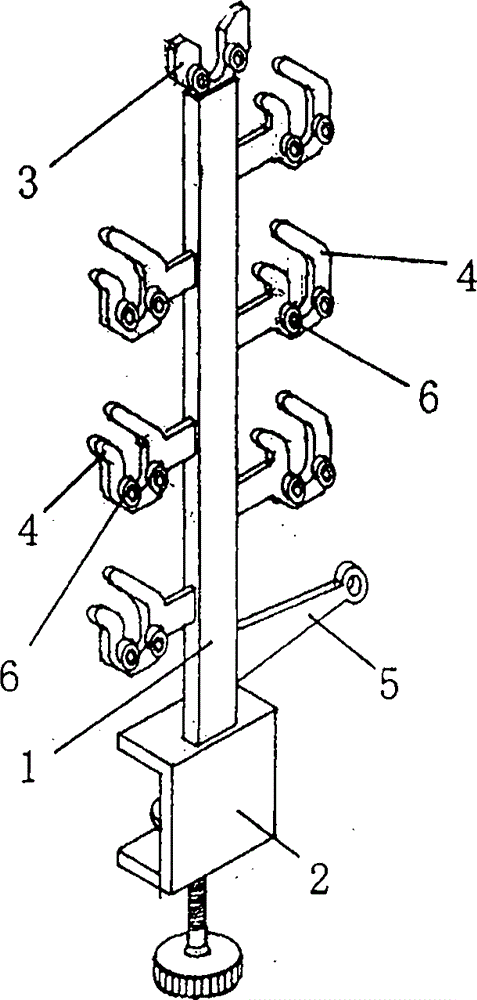

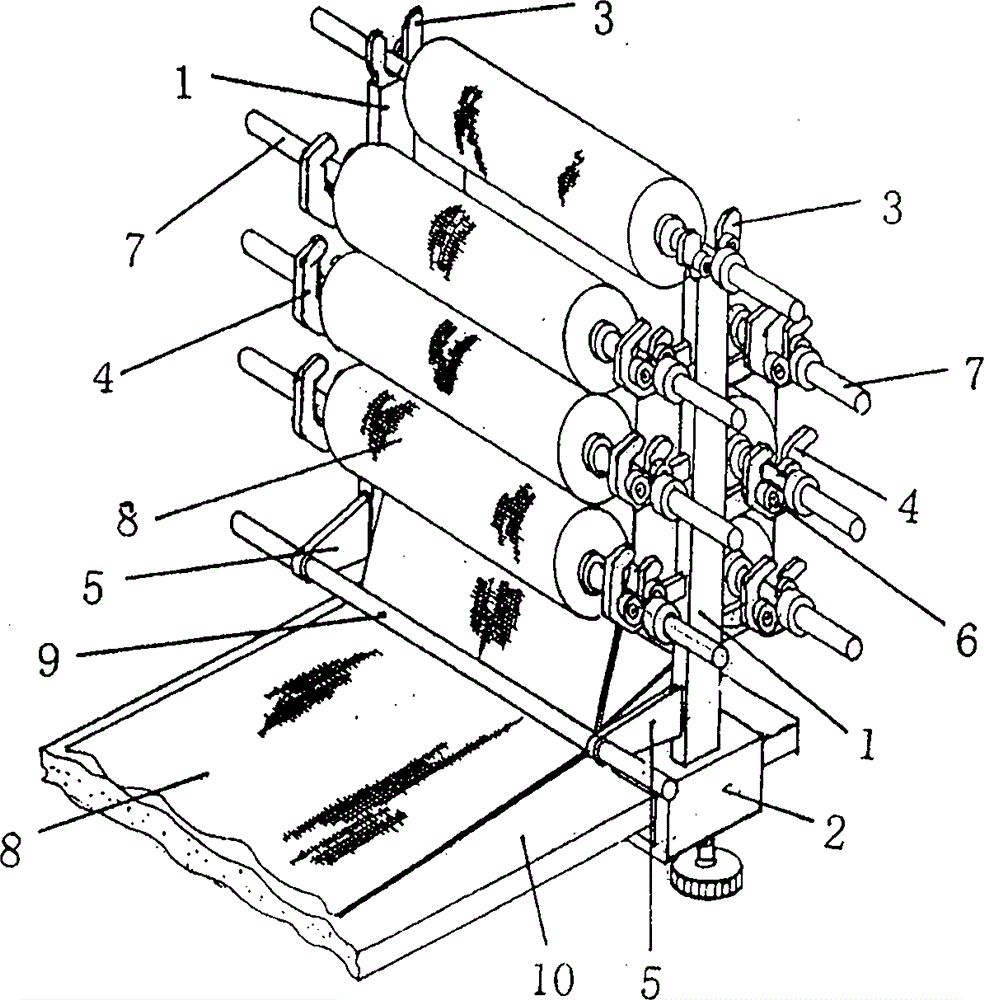

[0011] figure 1 , 2 As shown: there are several side forks 4 distributed on both sides of the pillar 1, and a cloth guide frame 5 is provided on the lower side. The distributed side fork 4 is equipped with the bearing 6 that flexibly rotates the cloth reel 7.

[0012] attached figure 2 As shown: the pillar 1 is fixed on both sides of the table 10 through the adjustment card 2, the fork 3 on the top and the several side forks 4 on both sides are placed with the cloth reel 7 with the cloth roll 8, and the several cloth placed Its cloth head of roll 8 is pulled downwards through the supporting rod 9 that is installed on the support 5 and is superimposed into several layers and tiled on the platen 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com