Screw type concrete stirrer

A concrete and agitator technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems affecting the flexibility of construction machinery, damage to blades, and inability to disassemble, so as to save maintenance time and increase flow speed , high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

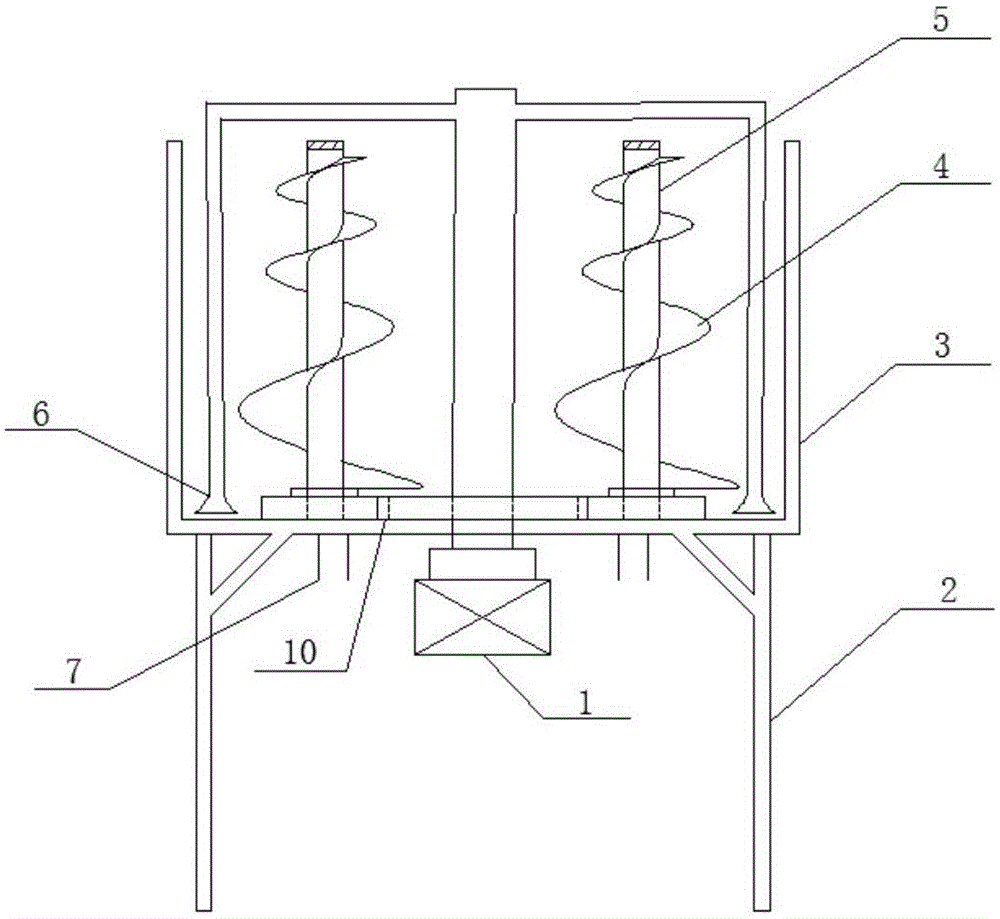

[0011] Such as figure 1 and figure 2 As shown, the spiral concrete mixer of the present invention mainly includes a motor 1, a frame 2, a chassis 10, a mixing bucket 3 and a mixing mechanism. The mixing bucket 3 is installed on the frame, and the chassis 10 is fixed on the bottom of the mixing bucket. There are more than two stirring mechanisms arranged on the chassis, and the motor 1 drives the stirring mechanisms to rotate through the transmission device.

[0012] Each stirring mechanism includes a stirring arm 5 and a spiral blade 4 detachably connected to the stirring arm. The spiral blades on adjacent stirring mechanisms rotate in opposite directions, and a discharge port 7 is provided at the bottom of the stirring barrel.

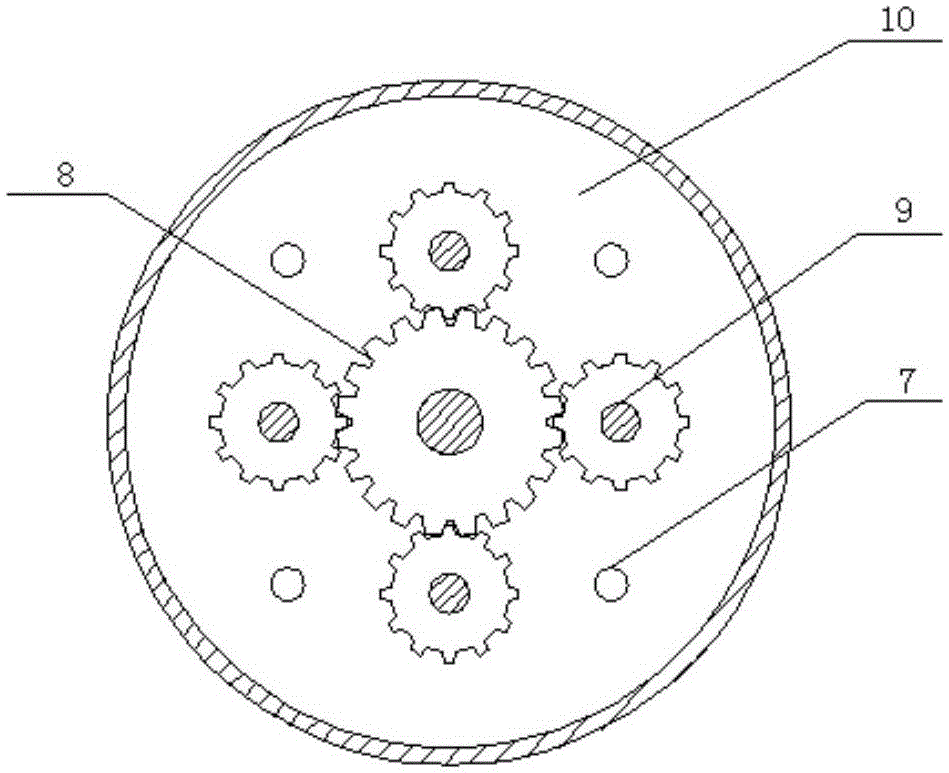

[0013] The transmission device includes a main gear 8 fixed on the chassis, and a secondary gear 9 meshed with the main gear. The number of the secondary gears is the same as that of the stirring arms, so that the stirring efficiency is higher; mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com