Laser cleaning device and method for oxide layers on surfaces of steel plates

A cleaning device and surface oxidation technology, which is applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of acidic waste liquid difficult to handle, physical injury of operators, ecological environment damage, etc., and achieve easy implementation , low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

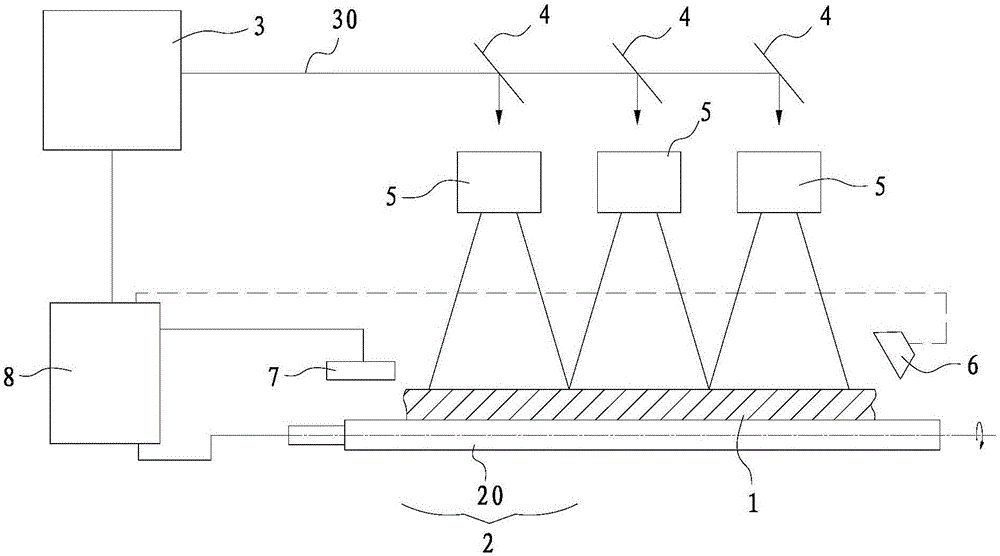

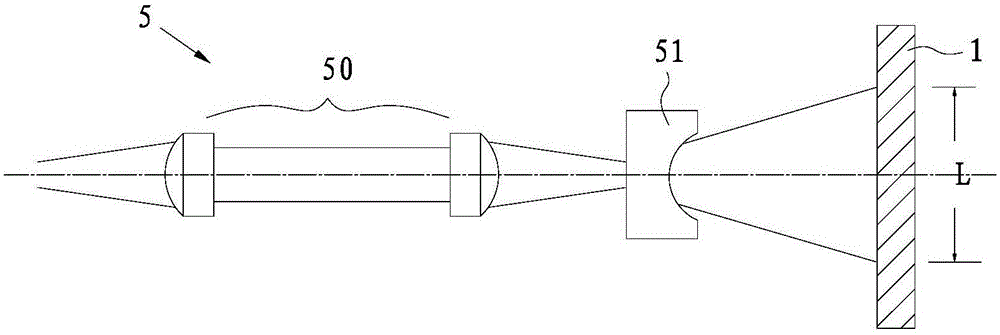

[0022] Such as figure 1 and figure 2 As shown, according to the present embodiment, a laser removal device for an oxide layer on the surface of a steel plate includes a carrying system 2 for placing the steel plate 1 horizontally and capable of driving the steel plate 1 to move along the front and rear directions; a laser capable of emitting a horizontal laser beam 30 3; a plurality of spectroscopes 4 for splitting the laser beam 30 and reflecting downward; one-to-one correspondence with the plurality of spectroscopes 4 and gathering the reflected light and scattering the derusting head 5 on the surface of the steel plate 1; The dust removal system 6 for collecting the removed oxide layer and the protection system 7 for introducing inert gas to the surface of the cleaned steel plate 1; and the central control for controlling the work of the carrying system 2, laser 3, dust removal system 6, and protection system 7 System 8, wherein a plurality of derusting heads 5 are distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com