Belt transmission characteristic parameter teaching model demonstrator

A technology of characteristic parameters and teaching models, applied to teaching models, instruments, educational tools, etc., can solve the problems of discontinuous increase in load, increase in teaching investment, and inability to measure the initial tension, so as to improve hands-on and operation ability and improve teaching The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

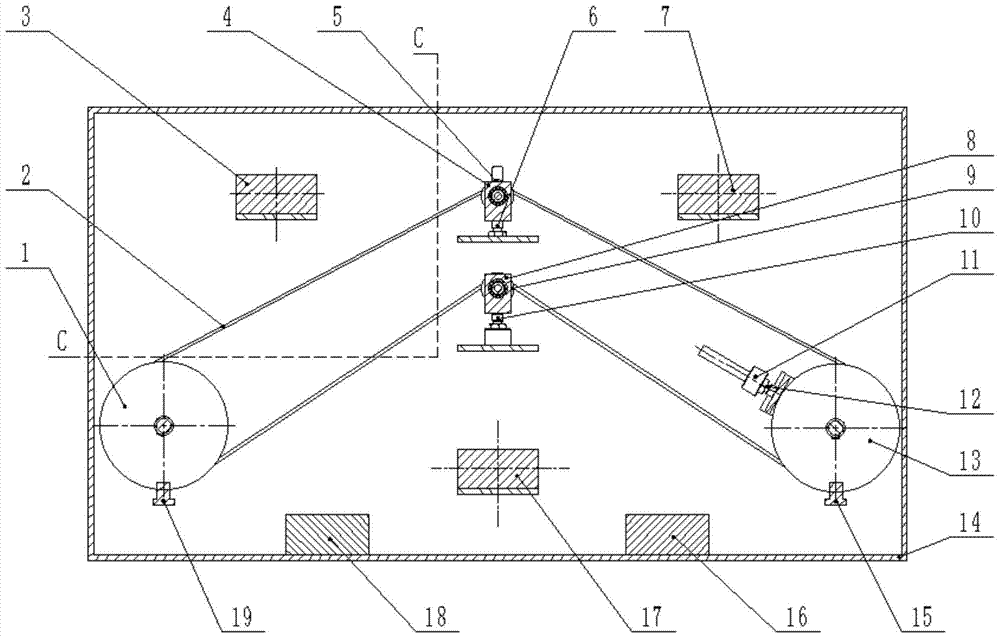

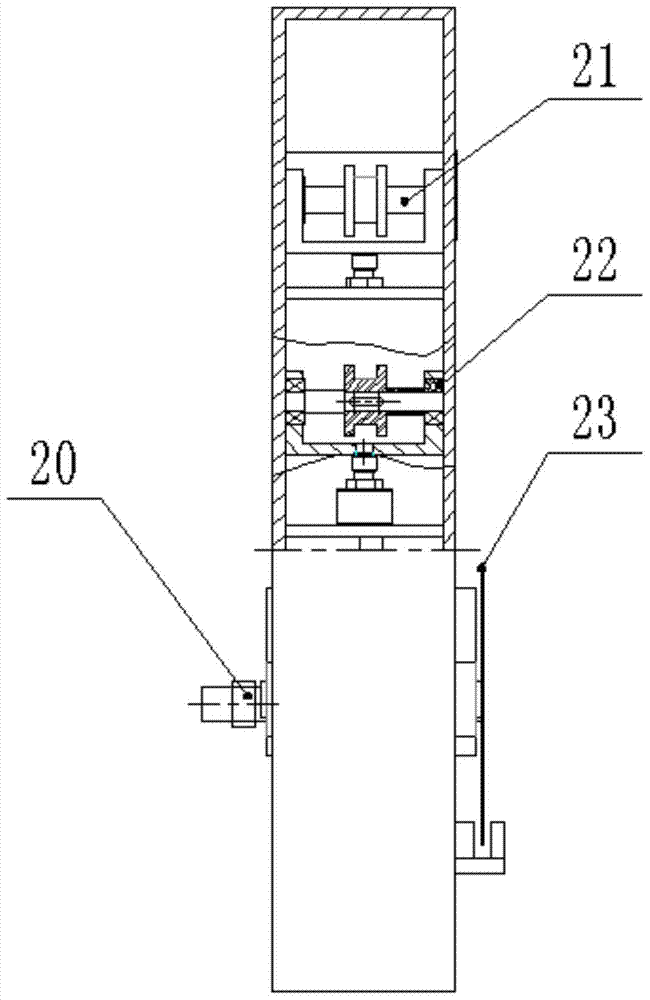

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

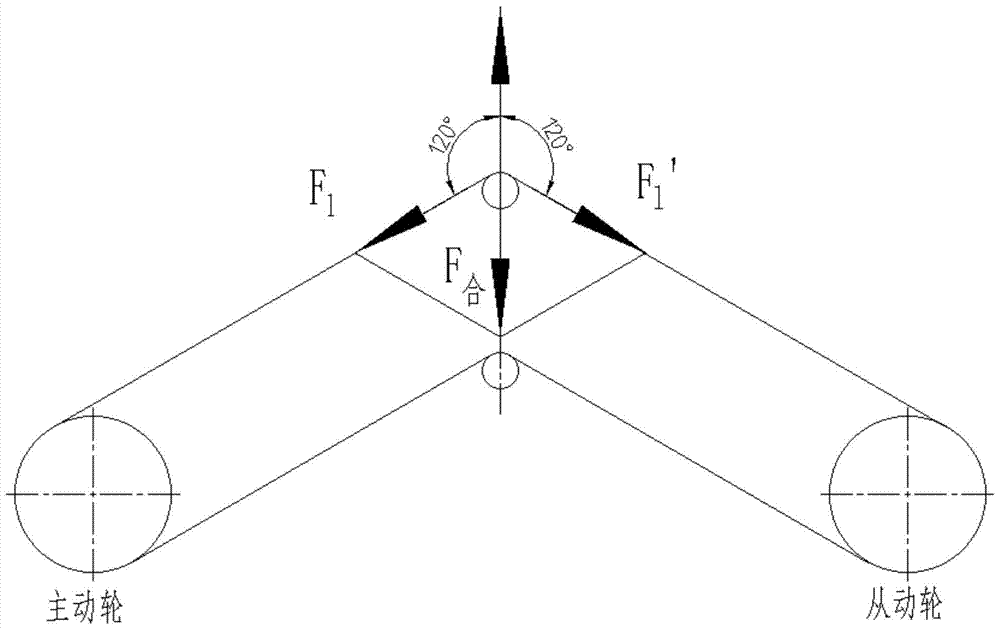

[0026] Implement a teaching and demonstration device for measuring the characteristic parameters of belt transmission, including driving wheels and driven wheels arranged horizontally and symmetrically. The passing wheel and the lower passing wheel of the belt form a belt transmission mechanism, and the angle between the belt when the upper passing wheel and the lower passing wheel position of the belt is 120°. The driving wheel is fixed on the plexiglass box through the shaft and the bearing, and the power is provided by the frequency conversion speed regulation motor connected to the driving pulley shaft at the rear of the box. This motor adopts frequency conversion speed regulation, which can realize stepless speed change. The driven pulley, the upper belt pulley and the lower pulley are respectively fixed on their re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com