Noise reduction method for vibration signal of mechanical equipment

A technology of vibration signal and mechanical equipment, applied in the field of noise reduction, can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

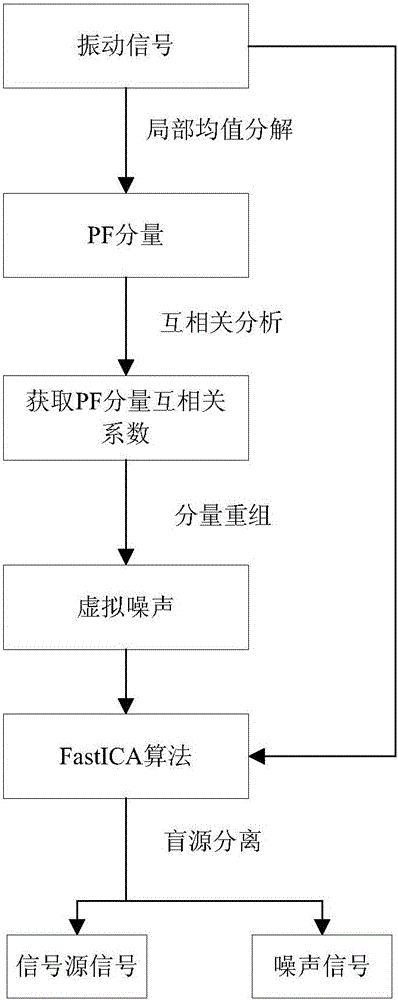

[0025] Such as figure 1 As shown, the present invention provides a noise reduction method for vibration signals of mechanical equipment, which is a method for joint noise reduction of vibration signals based on local mean decomposition and independent component analysis, which includes the following steps:

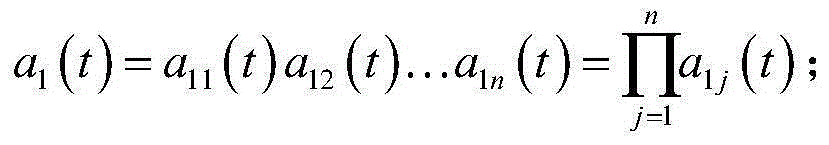

[0026] (1) Perform local mean value decomposition on the non-stationary vibration signal x(t), the steps are as follows:

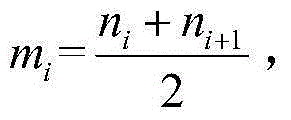

[0027] (1.1) Determine all local extremum points (including maxima and minima) n on the vibration signal x(t) i , calculate the average value m of all adjacent two extreme points i :

[0028] m i = n i + n i + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com