A thin liquid film corrosion test method with automatic control of liquid film thickness

A technology of liquid film thickness and corrosion test, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. The thickness of the liquid film on the surface of the electrode is changed, so as to achieve the effect of high degree of automation, improved performance and life, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific embodiments.

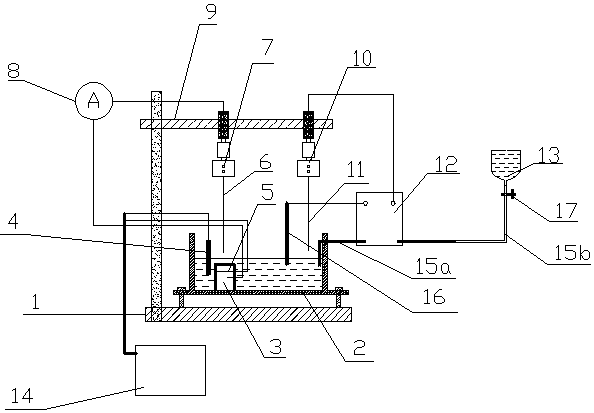

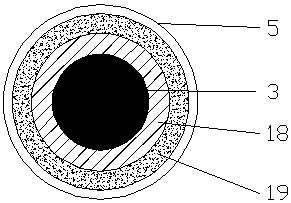

[0036] see figure 1 , the present invention can automatically control the thin liquid film corrosion test method of liquid film thickness, and this test method is carried out based on following test device, and this test device comprises iron frame platform 1, and the triangular seat with tiny horizontal bubble is placed on iron frame platform 1 and can be adjusted to test In the electrolytic cell 2, a spiral micrometer I7 and a spiral micrometer II10 are installed on the horizontal beam 9 above the iron frame 1 through a clamp, and the bottom of the spiral micrometer I7 and the spiral micrometer II10 are correspondingly welded with probes I6 and Probe II11, probe I6 and probe II11 are suspended above the electrolytic cell 2. A liquid storage tank 13 is connected with the liquid inlet of the electromagnetic valve 12 through a water pipe 15a with a control valve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com