Steel rail for passenger and freight mixed carrying and production method and application of steel rail

A rail, passenger and cargo technology, applied in the field of mixed passenger and cargo rails, can solve problems such as contact fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

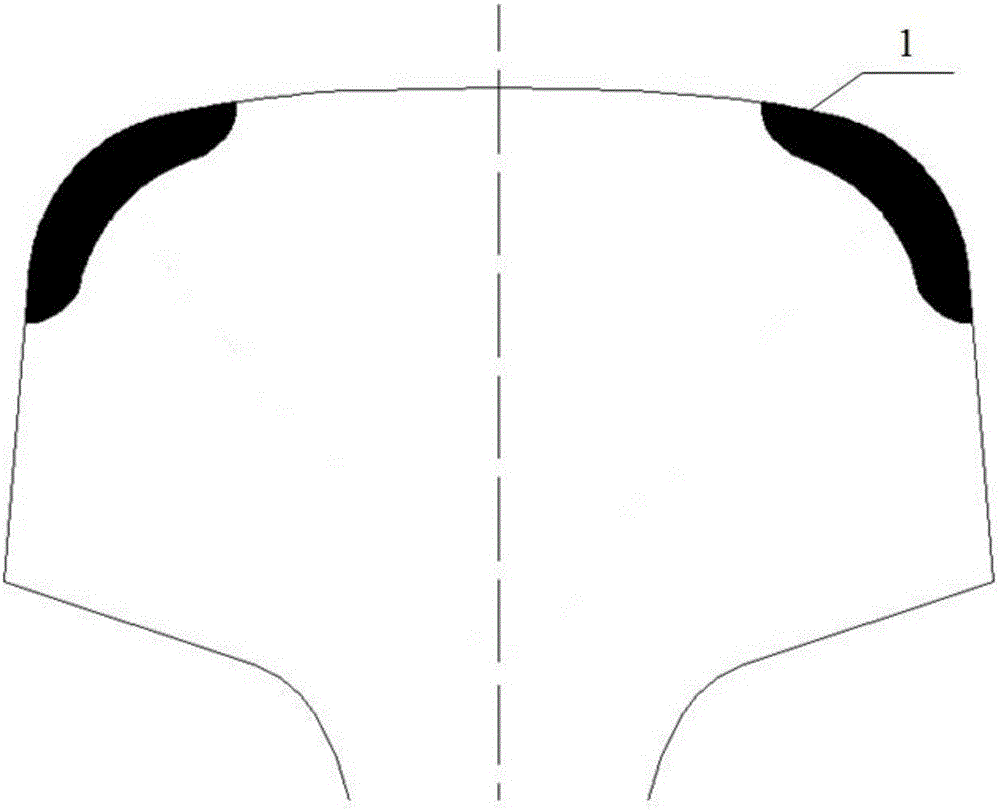

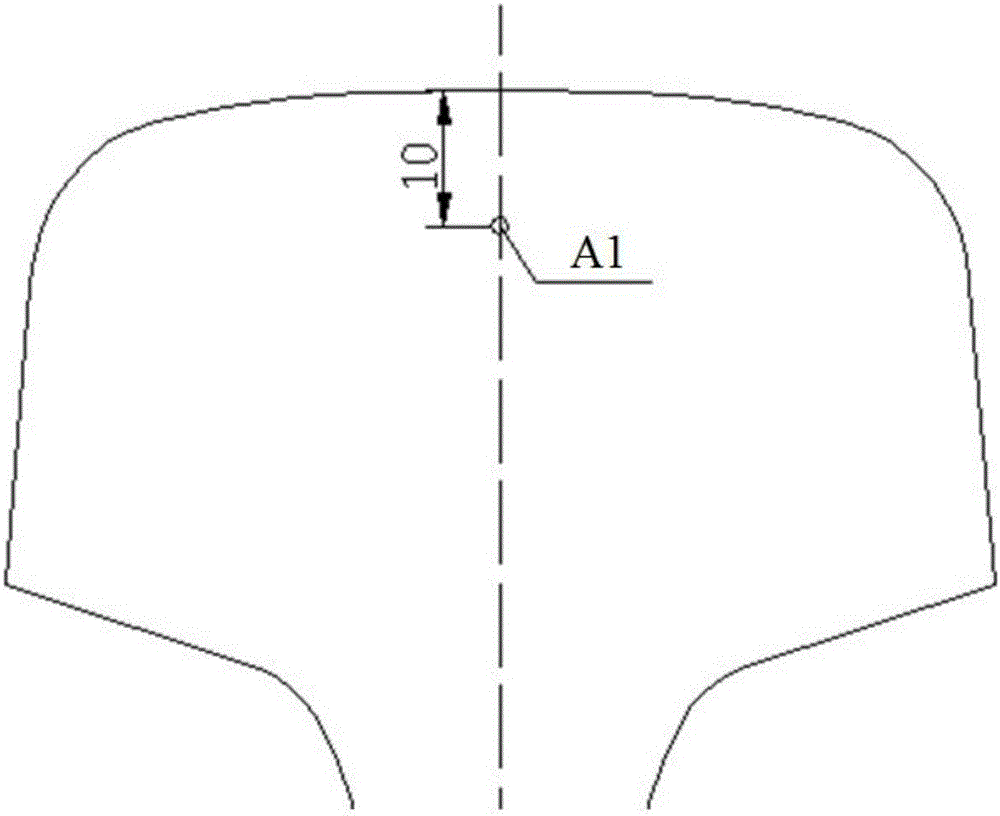

Embodiment 1

[0055] The steel containing the chemical composition No. 1 in Table 1 was blown by converter, LF refined, and RH vacuum treated and then cast into a continuous casting billet. Then the billet was sent to a walking heating furnace to be heated to 1300°C and held for 3 hours. The billet was rolled For the steel rail of the 60kg / m rail type, the steel rail after the final rolling is erected on the roller table by using a turning stand. The Kundao is transported at a speed of 4.8m / s, and the rail is rapidly cooled using a water-steam mixture as the cooling medium. The rapid cooling temperature is controlled to be 860°C, the cooling rate is 5.2°C / s, and the final cooling temperature is 446°C. After rapid cooling, the H 2 、C 2 h 2 and CH 4 The three gases are mixed into combustible gas at a volume ratio of 1:1.5:4, and the volume ratio of combustible gas to oxygen is 1:3, and the part of gauge angle 1 is heated by flame (such as Figure 5 Shown) in the form of rapid heating. Co...

Embodiment 2-5 and comparative example 1-5

[0057] Examples 2-5 follow the method of Example 1, but the operating process control parameters are different from those of Example 1. The specific operating process control parameters are shown in Table 2, and the rails prepared according to the method of Example 2-5 are A2-A5. The difference between the processing method in the comparative example and the embodiment is that the step of rapid heating and heat preservation after the rapid cooling is not carried out. The control parameters of the specific operation process are as shown in Table 2. The steel rail prepared according to the method of comparative examples 1-5 is D1 -D5.

[0058] Table 2

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com