Through operation platform for railway engineering truck

A technology for operating platforms and engineering vehicles, which is applied to railway car bodies, railway inspection cars, railway car body components, etc., and can solve the problems of many operators, low operating efficiency, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

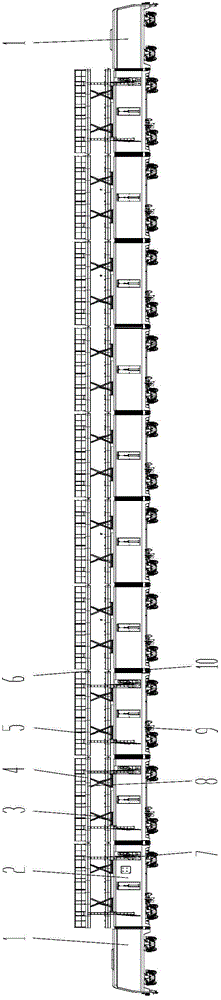

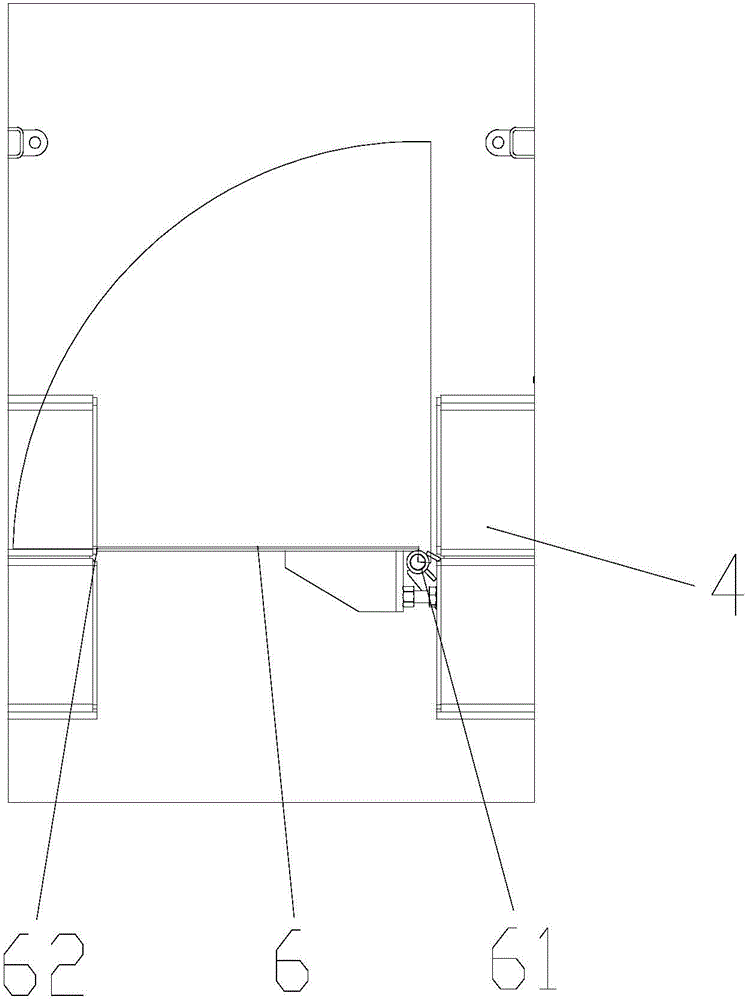

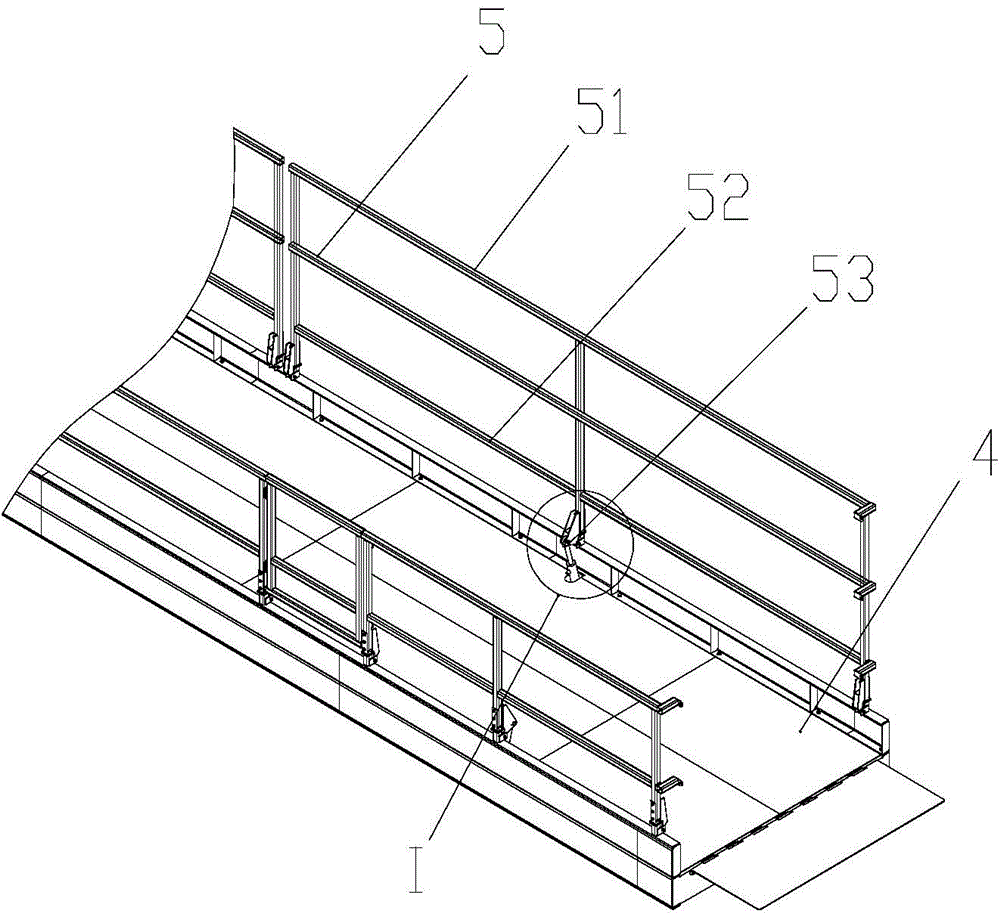

[0022] Attached below Figure 1-7 An embodiment of the present invention is described.

[0023] The through work platform used for railway engineering vehicles has a tractor 1 and a working vehicle 2 that provide power for the operation of the whole vehicle. The two tractors 1 are respectively placed at both ends of the vehicle, and the multiple working vehicles 2 are connected in series in sequence. Place them in the middle of two tractors 1 in a row, and connect between the plurality of working vehicles 2 and between the tractor 1 and the working vehicles 2 through folding windshields 10. The tops of each of the working vehicles 2 are equipped with a Lifting operating platforms 4, each of the operating platforms 4 is connected to the top of the vehicle body of the corresponding working vehicle 2 through bolts, and the lower part of each of the operating platforms 4 is provided with a scissor device 3 that drives the platform up and down. The bottom of each working vehicle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com