A powder spreader for rapid prototyping

A powder spreading device and fast technology, applied in the direction of manufacturing auxiliary devices, additive manufacturing, manufacturing tools, etc., can solve the problems of low density of molded parts, affecting the quality of molded parts, uneven thickness of powder layer, etc., to achieve powder thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail:

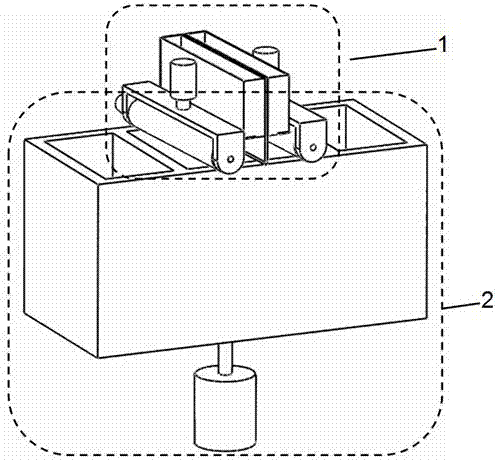

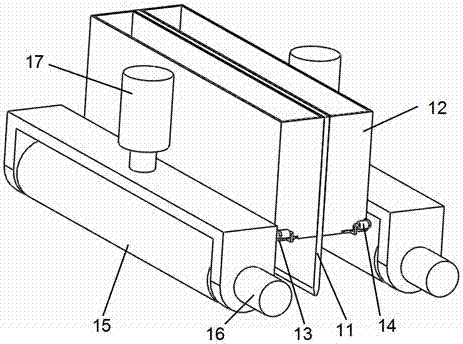

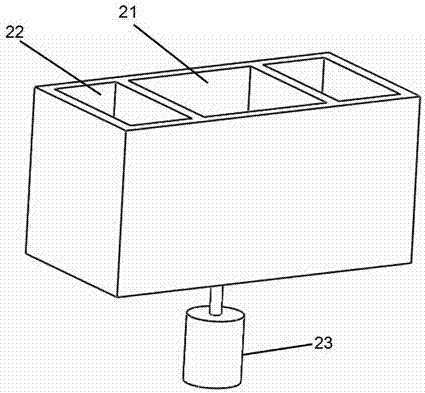

[0022] As shown in 1, a powder spreading device for rapid prototyping manufacturing includes a powder spreading compaction system 1 and a molding system 2 . Among them, the powder spreading compaction system 1 such as figure 2 As shown, it includes a scraper 11, a hopper 12 arranged on both sides of the scraper, a baffle 13 located at the lower end of the hopper, an unloading motor 14 that drives the baffle to open the hopper for unloading, a lifting drive device arranged on the hopper, and a setting Press roller assembly at the output of the lift drive. Wherein, the lifting driving device adopts the air cylinder 17, and the pressing roller assembly includes a pressing roller seat, a pressing roller 15 arranged on the pressing roller seat, and a pressing roller driving motor 16. Forming system 2 such as image 3 As shown, it includes a molding cylinder 21, a recovery cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com