Butt joint chip removal groove

A chip flute and sub-groove technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as poor sealing of joints, large pollution of cutting fluid, and harsh workshop environment, and achieve production Low cost, long service life, and the effect of ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

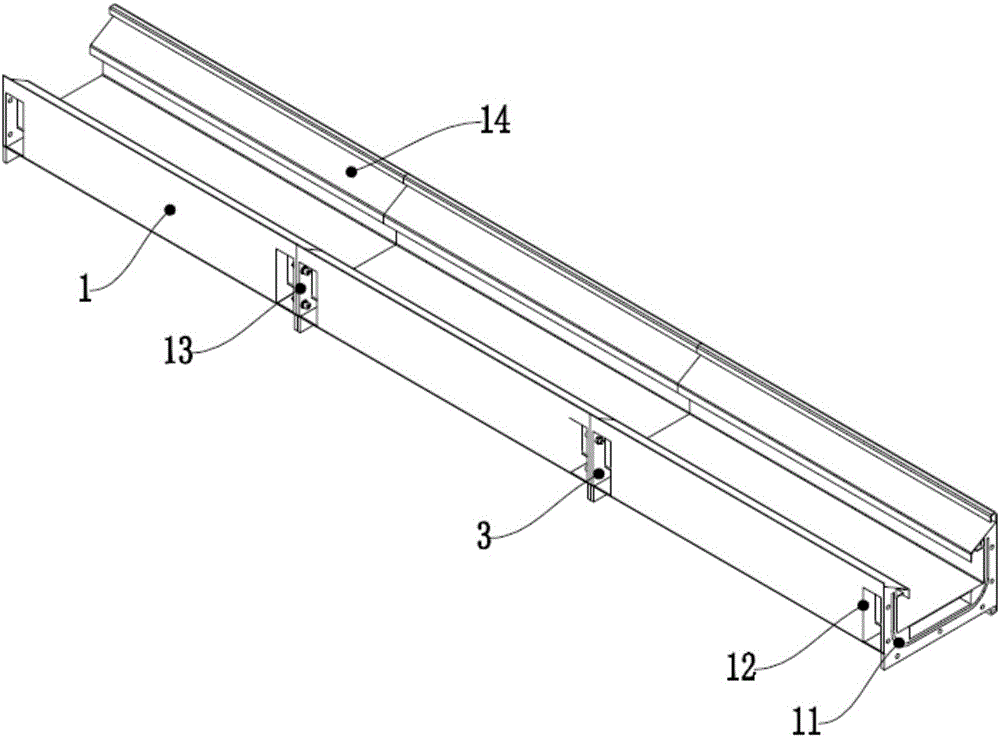

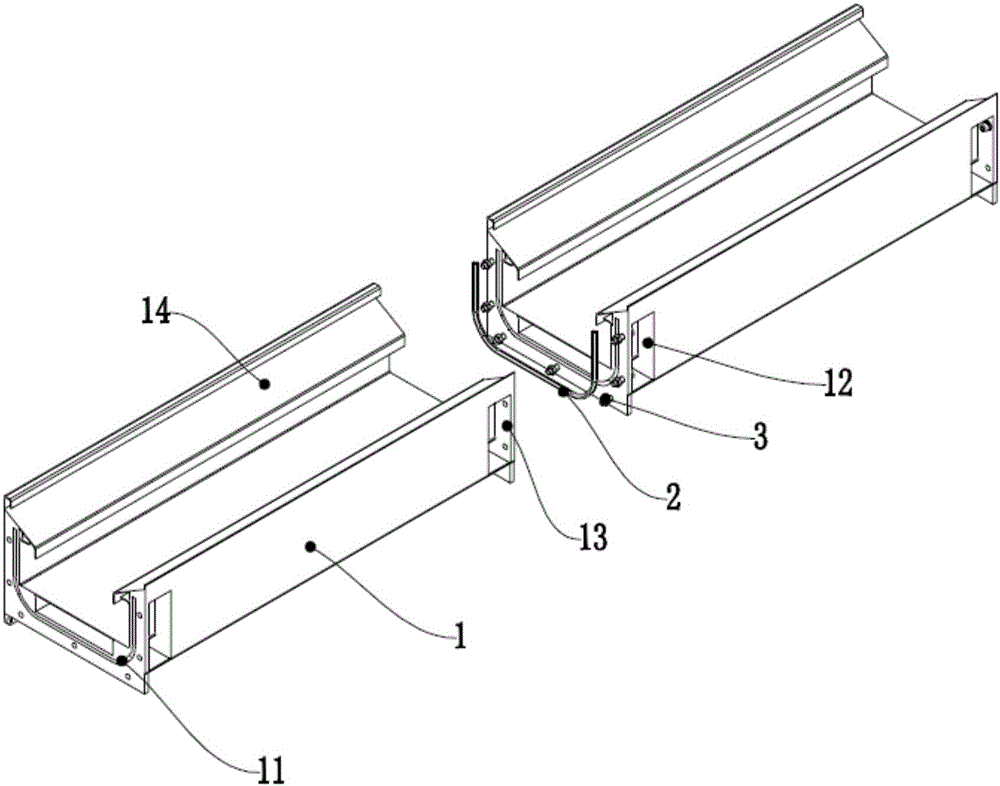

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

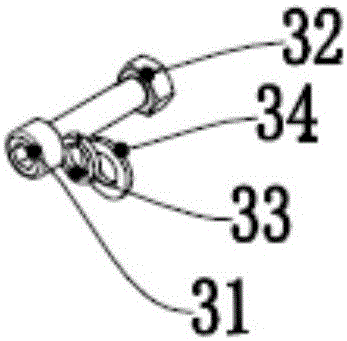

[0021] A butt joint chip removal flute, which is assembled from multiple chip removal sub-grooves 1. The chip removal sub-grooves 1 are U-shaped groove structures with an upward opening, and the assembly surfaces of the chip removal sub-grooves 1 are symmetrically arranged. The U-shaped grooves 11 are sealed and connected between adjacent chip removal sub-grooves 1 through the sealing strip 2 embedded in the above-mentioned U-shaped grooves 11 .

[0022] The drainage chip removal groove is assembled by multi-section chip removal sub-grooves 1, which is easy to install, simplifies the structure, and reduces the cost. The adjacent chip removal sub-grooves 1 are sealed and connected by the sealing strip 2 embedded in the U-shaped groove 11. When installing, the sealing strip 2 is nested and installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com