Fume cupboard for laboratory

A laboratory fume hood technology, applied in the field of laboratory equipment, can solve the problems of affecting the experimental results, uneven wind speed, excessive wind speed in the work area, etc., and achieve the effect of ensuring safety, convenient operation and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

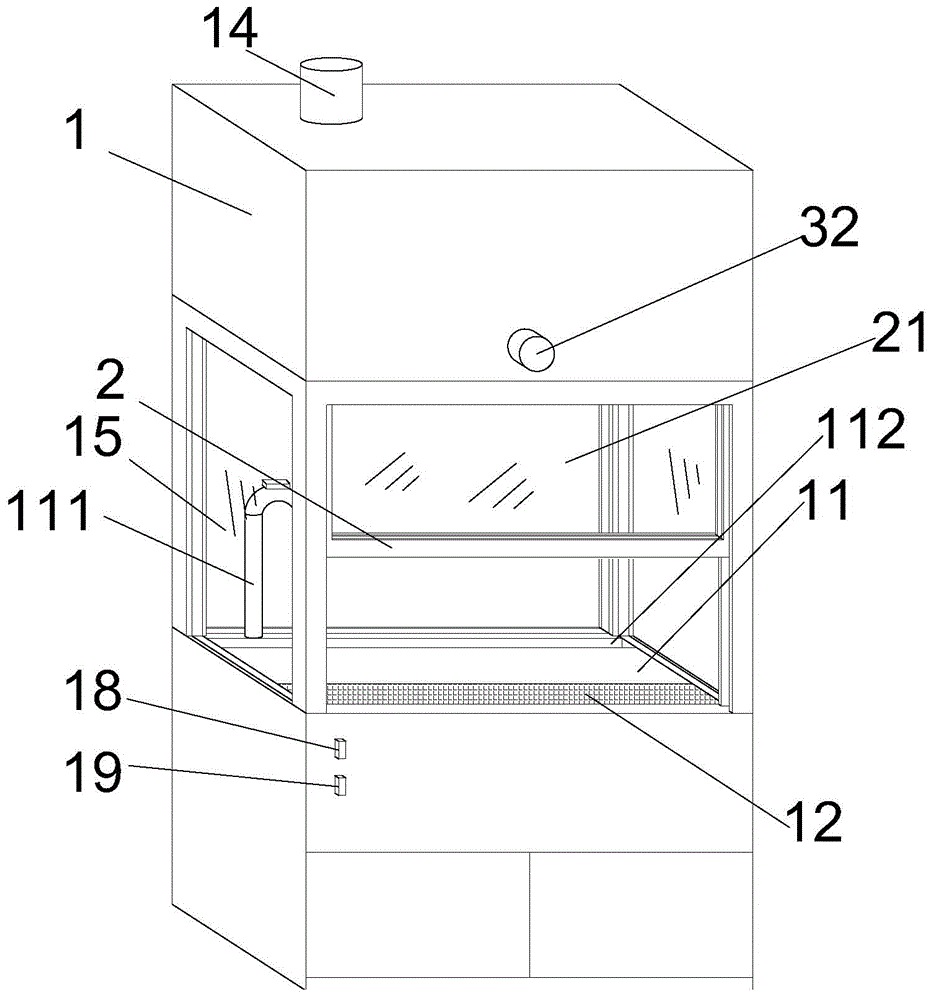

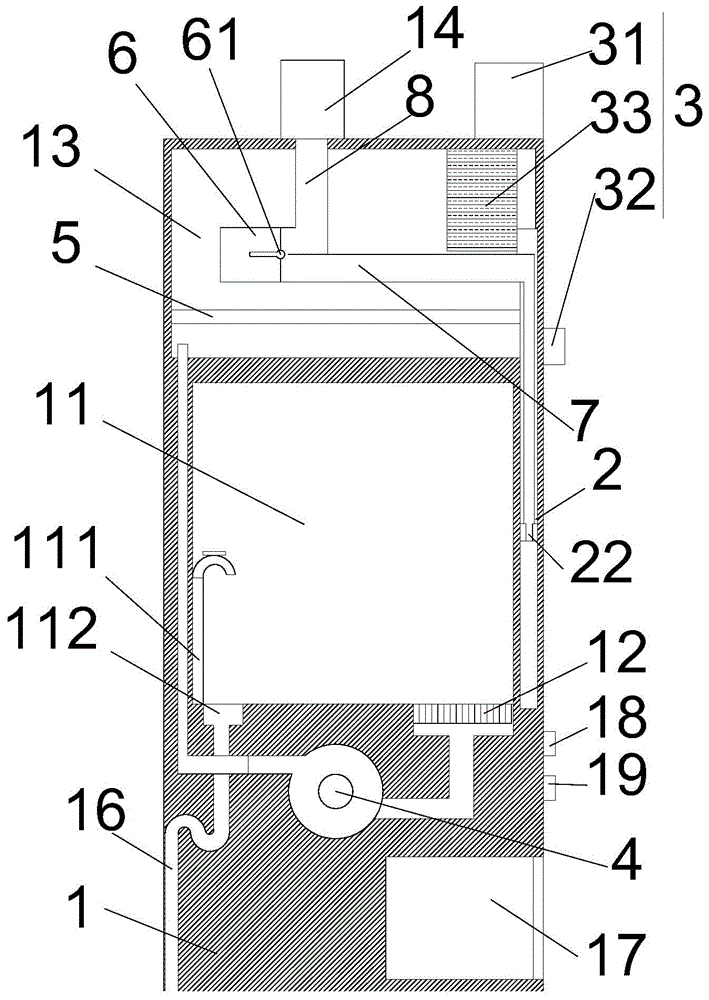

[0018] refer to figure 1 and figure 2 As shown, a kind of laboratory fume hood proposed by the present invention comprises a cabinet body 1, a cabinet door 2 and a control mechanism 3;

[0019] A fan 4, a filter screen 5, a shunt pipe 6, a first air guide pipe 7 and a second air guide pipe 8 are installed in the cabinet body 1; an operating room 11, an air inlet channel 12 and a filter chamber 13 are arranged in the cabinet body 1, The cabinet door 2 is movably installed on the cabinet body 1 and is located on one side of the operating room 11. The movement of the cabinet door 2 can adjust the contact area between the operating room 11 and the external connection. The first observation window 21 is installed on the cabinet door 2; the air inlet channel 12 is located at the bottom of the operating room 11 close to the side of the cabinet door 2, the air inlet channel 12 is connected to the air inlet of the fan 4, and the air outlet of the fan 4 is connected to the filter cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com