Mechanical automation crown sealing equipment for trees and nursery stocks

A seedling and tree technology, applied in the field of mechanical automation crown sealing equipment, can solve the problems of high crown damage rate, low work efficiency, unreliable rope winding, etc., to reduce labor intensity, save labor costs, and improve the effect of crown sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

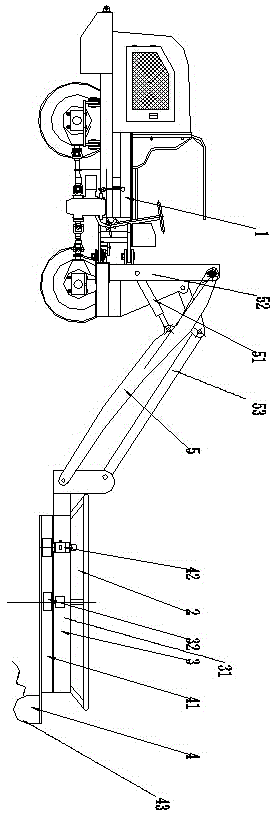

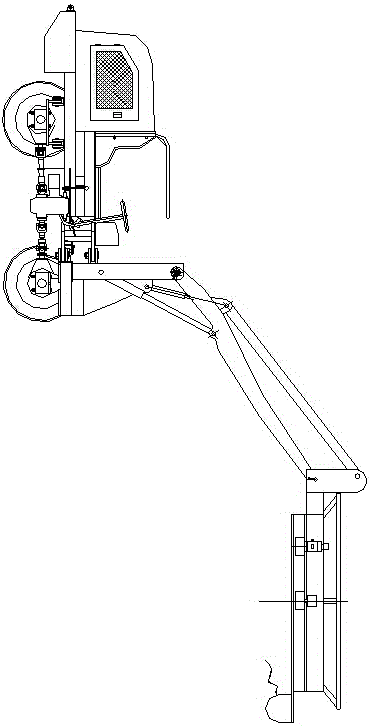

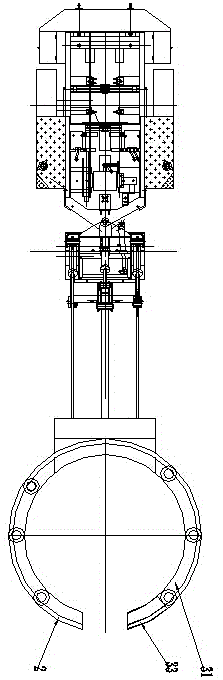

[0017] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0018] like Figure 1-6 As shown, this mechanical automatic crown sealing equipment for trees and seedlings includes a center positioning device 2, a track device 3, a rope winding crown sealing device 4 and a lifting device 5 that are arranged on the vehicle body 1. The lifting device The device 5 is fixedly arranged at the rear of the vehicle body 1, the center positioning device 2 and the track device 3 are both arranged in a circular shape with an opening, and the center positioning device 2 is correspondingly arranged on the upper part of the track device 3 and is fixed as a whole, After the central positioning device 2 locates the crowns of trees and seedlings, the track device 3 forms a closed circular track, and the rope winding crown sealing device 4 is arranged on one side of the track device 3. The end of the lifting device 5 is rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com